Organic-inorganic composite membrane based on carboxyl-containing sulfonated polyaryletherketone sulfone and Im-MOF-801 and preparation method of organic-inorganic composite membrane

A technology for sulfonated polyaryletherketone sulfone and sulfonated polyaryletherketone is applied in the field of organic-inorganic composite membranes and their preparation, and can solve the problems of poor compatibility, affecting the performance of proton exchange membranes, and lack of proton conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

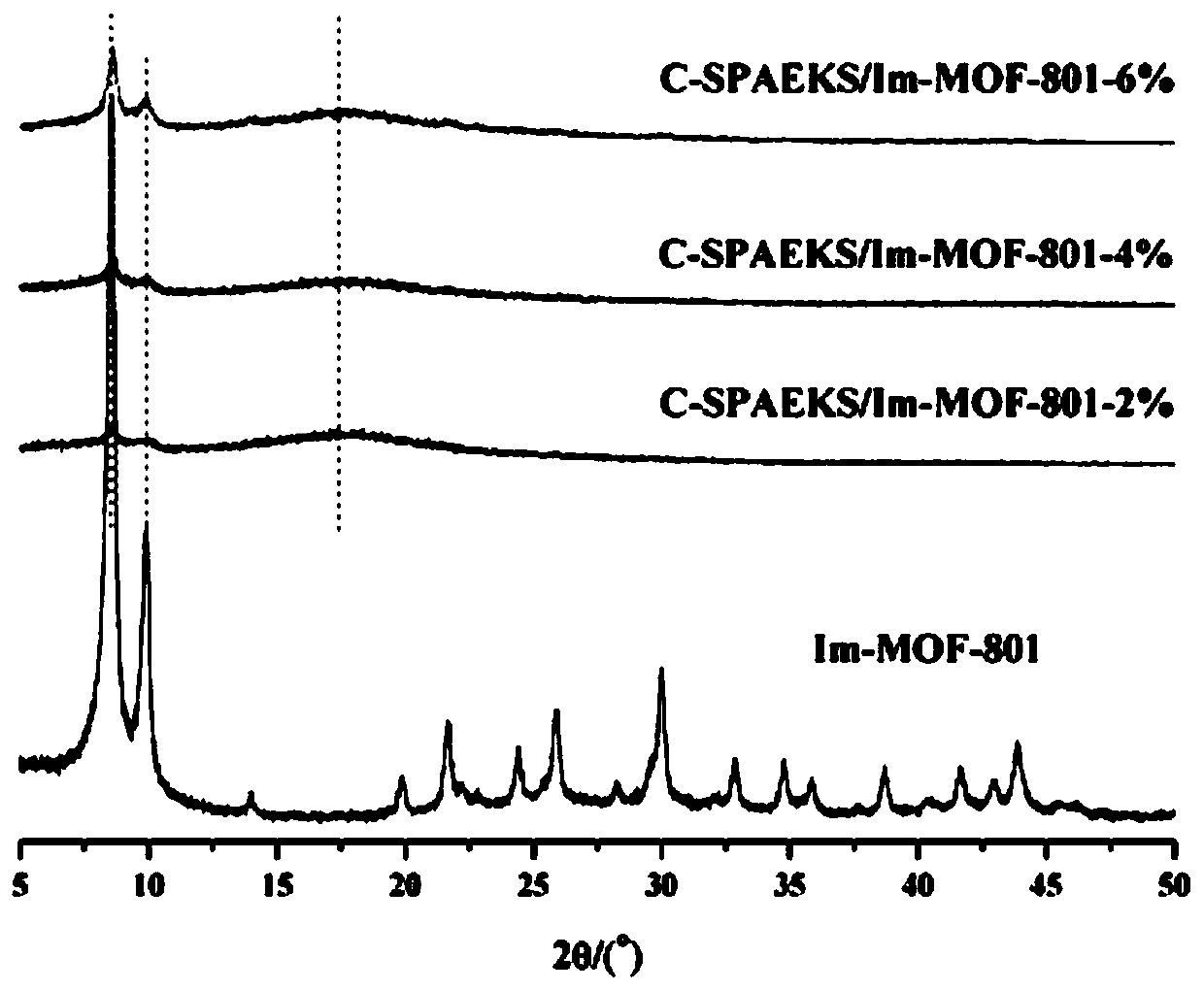

[0031] A method for preparing an organic-inorganic proton exchange composite membrane based on carboxyl-containing sulfonated polyaryletherketone sulfone polymer and Im-MOF-801, the specific steps are as follows:

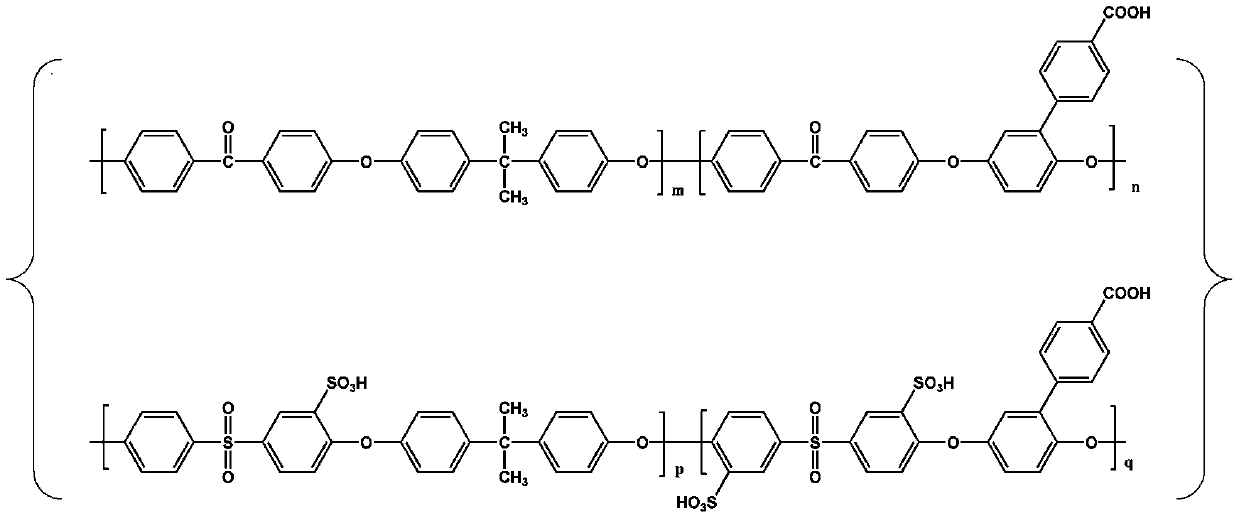

[0032] (1) Weigh 0.5g of C-SPAEKS polymer into a beaker, add 10ml of NMP solvent, stir at room temperature to dissolve the polymer, and obtain a uniform solution. Among them, C-SPAEKS represents carboxyl-containing sulfonated polyarylether ketone sulfone; NMP represents N-methyl-2-pyrrolidone.

[0033] (2) Weigh 0.01g of Im-MOF-801 powder and add it to the homogeneous solution in step (1). The obtained mixed liquid was ultrasonically dispersed for 4 hours, and then stirred for 48 hours to obtain a film-forming liquid. Among them, Im-MOF-801 represents a metal organic framework material containing a coordinated imidazole; the mass fraction of Im-MOF-801 in the C-SPAEKS matrix in the film-forming solution is 2wt%.

[0034] (3) Cast the film-forming solution obtained...

Embodiment 2

[0045] (1) Weigh 0.5 g of C-SPAEKS polymer into a beaker, add 10 ml of NMP solvent, stir at room temperature to dissolve the polymer, and obtain a uniform solution. Among them, C-SPAEKS represents carboxyl-containing sulfonated polyarylether ketone sulfone; NMP represents N-methyl-2-pyrrolidone.

[0046] (2) Weigh 0.02g of Im-MOF-801 powder and add it to the homogeneous solution in step (1). The obtained mixed liquid was ultrasonically dispersed for 4 hours, and then stirred for 60 hours to obtain a film-forming liquid. Among them, Im-MOF-801 represents the metal organic framework material containing coordination imidazole; the mass fraction of Im-MOF-801 in the C-SPAEKS matrix in the film-forming solution is 4wt%.

[0047] (3) Cast the film-forming solution obtained in step (2) onto a clean glass plate, dry it at 80°C for 48 hours, cool it down to room temperature naturally, and remove the film in water to obtain C-SPAEKS / Im-MOF-801 Composite film.

[0048] (4) Soak the C-...

Embodiment 3

[0051] (1) Weigh 0.5 g of C-SPAEKS polymer into a beaker, add 10 ml of NMP solvent, stir at room temperature to dissolve the polymer, and obtain a uniform solution. Among them, C-SPAEKS represents carboxyl-containing sulfonated polyarylether ketone sulfone; NMP represents N-methyl-2-pyrrolidone.

[0052] (2) Weigh 0.03g of Im-MOF-801 powder and add it to the homogeneous solution in step (1). The obtained mixed liquid was ultrasonically dispersed for 4 hours, and then stirred for 72 hours to obtain a film-forming liquid. Among them, Im-MOF-801 represents a metal organic framework material containing a coordinated imidazole; the mass fraction of Im-MOF-801 in the C-SPAEKS matrix in the film-forming solution is 6 wt%.

[0053] (3) Cast the film-forming solution obtained in step (2) onto a clean glass plate, dry it at 80°C for 48 hours, cool it down to room temperature naturally, and remove the film in water to obtain C-SPAEKS / Im-MOF-801 Composite film.

[0054] (4) Soak the C-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com