Thermal insulation coating for building exterior walls and preparation method of thermal insulation coating

A technology for thermal insulation and building exterior walls, applied in conductive coatings, reflective/signal coatings, anti-fouling/underwater coatings, etc., can solve the problems of many steps in the production process, complex processes, and thermal insulation properties that need to be improved. Achieve the effects of improving thermal insulation performance, increasing microporosity, good antibacterial and antifungal performance and waterproof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

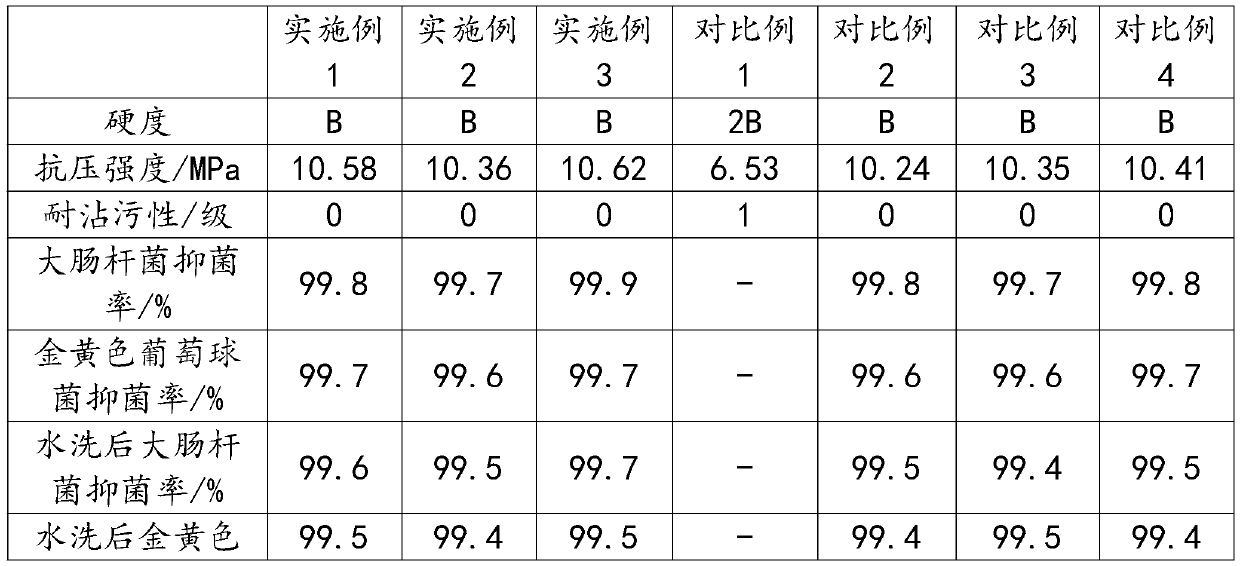

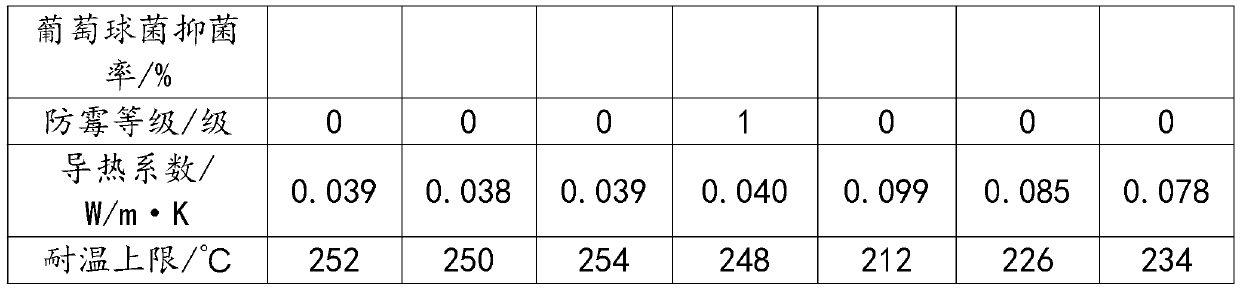

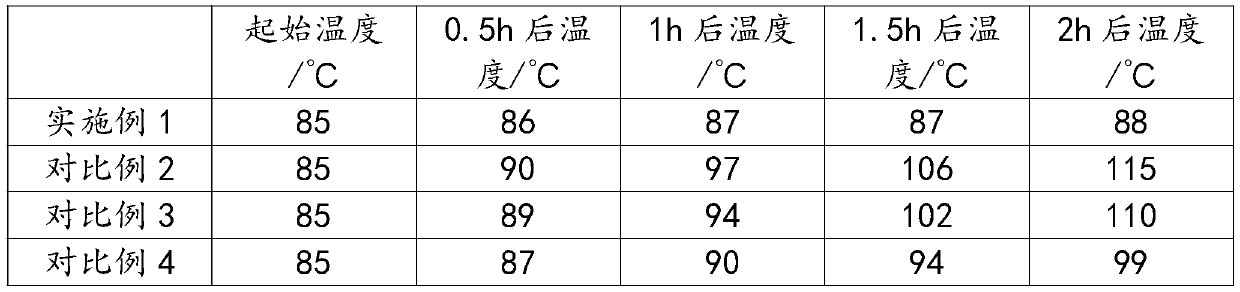

Examples

preparation example Construction

[0045] The preparation method of this coating is as follows:

[0046] Add modified composite airgel, modified polyurethane, floating beads, rutile titanium dioxide, silicon carbide, Glauber’s salt and additives into the reaction kettle in succession, stir at 200r / min for 30-40min, and then pass through a high-speed dispersing grinder Grind for 10-12min, then stir at 3000r / min for 25-30min to obtain thermal insulation coating.

Embodiment 1

[0048] A thermal insulation coating for building exterior walls, made of the following raw materials in parts by weight: 50 parts of modified polyurethane, 30 parts of modified composite airgel, 8 parts of floating beads, 1.5 parts of rutile titanium dioxide, and 1.5 parts of silicon carbide , Glauber's salt 2 parts, auxiliary agent 0.6 part;

[0049] The paint is made by the following method:

[0050] Add modified composite airgel, modified polyurethane, floating beads, rutile titanium dioxide, silicon carbide, Glauber’s salt and additives into the reaction kettle in succession, stir at 200r / min for 30min, and then grind for 10min with a high-speed dispersing grinder , and then stirred at 3000r / min for 25min to obtain the thermal insulation coating.

Embodiment 2

[0052] A thermal insulation coating for building exterior walls, made of the following raw materials in parts by weight: 55 parts of modified polyurethane, 33 parts of modified composite airgel, 10 parts of floating beads, 1.8 parts of rutile titanium dioxide, and 1.8 parts of silicon carbide , Glauber's salt 2.8 parts, auxiliary agent 0.8 part;

[0053] The paint is made by the following method:

[0054] Add modified composite airgel, modified polyurethane, floating beads, rutile titanium dioxide, silicon carbide, Glauber’s salt and additives into the reaction kettle in succession, stir at 200r / min for 35min, and then grind for 11min in a high-speed dispersing grinder , and then stirred at 3000r / min for 27min to obtain the thermal insulation coating.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com