Concrete containing regenerated micro powder and preparation method thereof

A technology of recycled micropowder and concrete, which is applied in the field of concrete, can solve problems such as air pollution and human health effects, and achieve the effects of prolonging service life, enhancing anti-ultraviolet performance, and improving compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

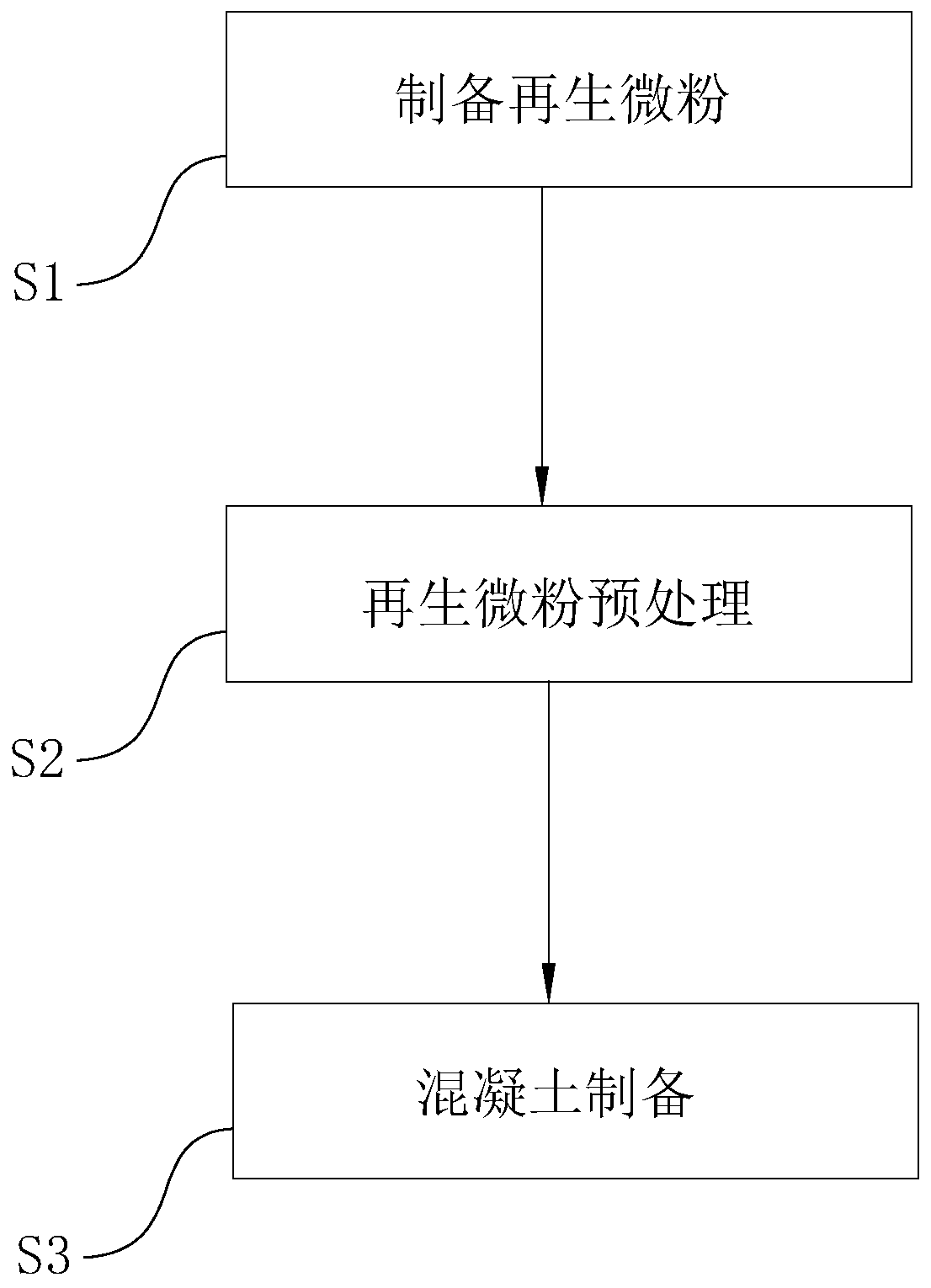

Method used

Image

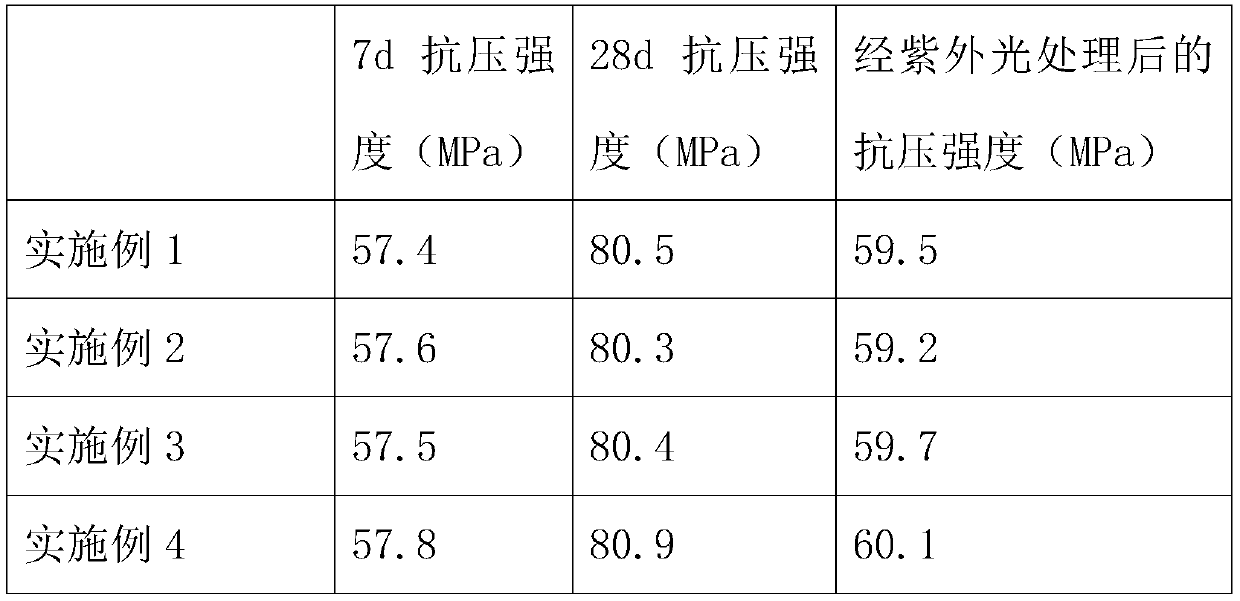

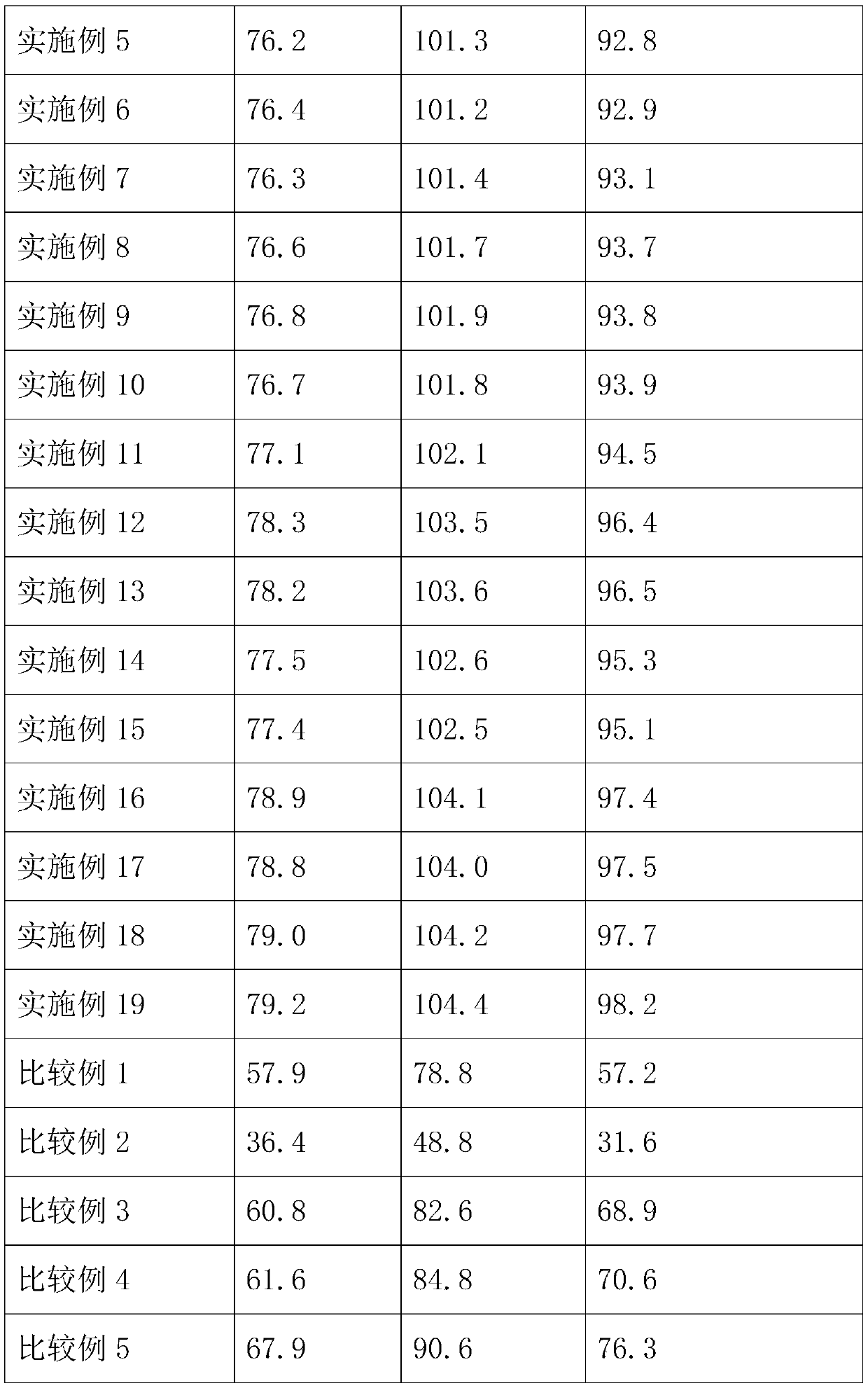

Examples

Embodiment 1

[0069] A concrete containing recycled micropowder, comprising the following components:

[0070] Portland cement 17.5kg; water 6.5kg; sand 32.5kg; stone 42.5kg; recycled micropowder 1kg.

[0071] The preparation method of concrete containing recycled micropowder is as follows:

[0072] S1. Preparation of regenerated micropowder: put construction waste into the crusher and crush it into regenerated micropowder with a particle size of 0.1-0.15 mm, and then use a screen to screen out the particles with too large particle size and put them back into the crusher for recrushing until All particles that are crushed pass through the sieve.

[0073] S2. Concrete preparation: Add 17.5kg of Portland cement into a 150L stirring tank, stir at a speed of 250r / min at room temperature, add 6.5kg of water while stirring, and then add sand while stirring 32.5kg, 42.5kg of stone and 1kg of the regenerated micropowder prepared by S1, after stirring evenly, the concrete containing the regenerate...

Embodiment 2

[0075] A concrete containing recycled micropowder, comprising the following components:

[0076] Portland cement 15kg; water 8kg; sand 35kg; stone 40kg; recycled micropowder 1.2kg.

[0077] The preparation method of concrete containing recycled micropowder is as follows:

[0078] S1. Preparation of regenerated micropowder: put construction waste into the crusher and crush it into regenerated micropowder with a particle size of 0.1-0.15 mm, and then use a screen to screen out the particles with too large particle size and put them back into the crusher for recrushing until All particles that are crushed pass through the sieve.

[0079] S2. Concrete preparation: Add 15kg of Portland cement into a 150L stirring tank, and stir at a speed of 250r / min under normal temperature conditions, add 8kg of water while stirring, and after stirring evenly, add 35kg of sand while stirring, 40kg of stone and 1.2kg of regenerated micropowder prepared by S1, after stirring evenly, the concrete ...

Embodiment 3

[0081] A concrete containing recycled micropowder, comprising the following components:

[0082] Portland cement 20kg; water 5kg; sand 30kg; stone 45kg; recycled micropowder 0.7kg.

[0083] The preparation method of concrete containing recycled micropowder is as follows:

[0084] S1. Preparation of regenerated micropowder: put construction waste into the crusher and crush it into regenerated micropowder with a particle size of 0.1-0.15 mm, and then use a screen to screen out the particles with too large particle size and put them back into the crusher for recrushing until All particles that are crushed pass through the sieve.

[0085] S2. Concrete preparation: Add 20kg of Portland cement into a 150L mixing tank, stir at a speed of 250r / min at room temperature, add 5kg of water while stirring, and then add 30kg of sand while stirring, 45kg of stone and 0.7kg of regenerated micropowder prepared by S1, after stirring evenly, the concrete containing regenerated micropowder can b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com