Refining method of Mg2Si phase in Mg-Al-Si series alloy

A mg-al-si and alloy technology, applied in the field of metal materials, can solve the problems of plasticity decline in mechanical properties of alloys, and achieve the effect of improving strength and plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Taking 10kg as an example, prepare a cast magnesium alloy according to the ratio of Mg-5Al-2Si-0.1Ce (that is, the composition content of the magnesium alloy is: 5% Al, 2% Si, 0.1% Ce, and the rest is Mg and unavoidable impurities) . Specific steps are as follows:

[0034] (1) The Mg-5Al-2Si alloy ingot is melted in a crucible furnace at 690° C. according to the conventional magnesium alloy smelting method;

[0035] (2) Inoculation and modification treatment: when the temperature of the melt rises to 765°C, quickly add the Mg-Ce master alloy into the metal melt to reduce the burning loss of the Ce element, and keep it warm for 25 minutes to ensure that all the added Mg-Ce alloy is melt;

[0036] (3) Stirring and slag removal: keep the temperature of the molten metal at 745°C, and stir the molten metal clockwise from top to bottom twice every 10 minutes. Stirring should be uniform and efficient to ensure that all the added intermediate alloys are melted , and the Ce e...

Embodiment 2

[0040] Taking 10kg as an example, prepare a cast magnesium alloy according to the ratio of Mg-5Al-2Si-0.4Ce (that is, the composition content of the magnesium alloy is: 5% Al, 2% Si, 0.4% Ce, and the rest is Mg and unavoidable impurities) ; Concrete steps are with embodiment 1.

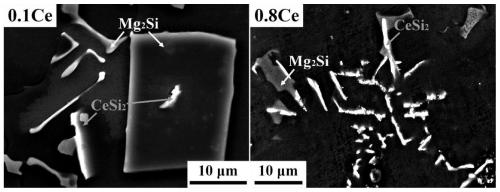

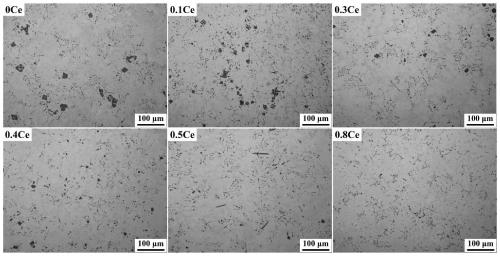

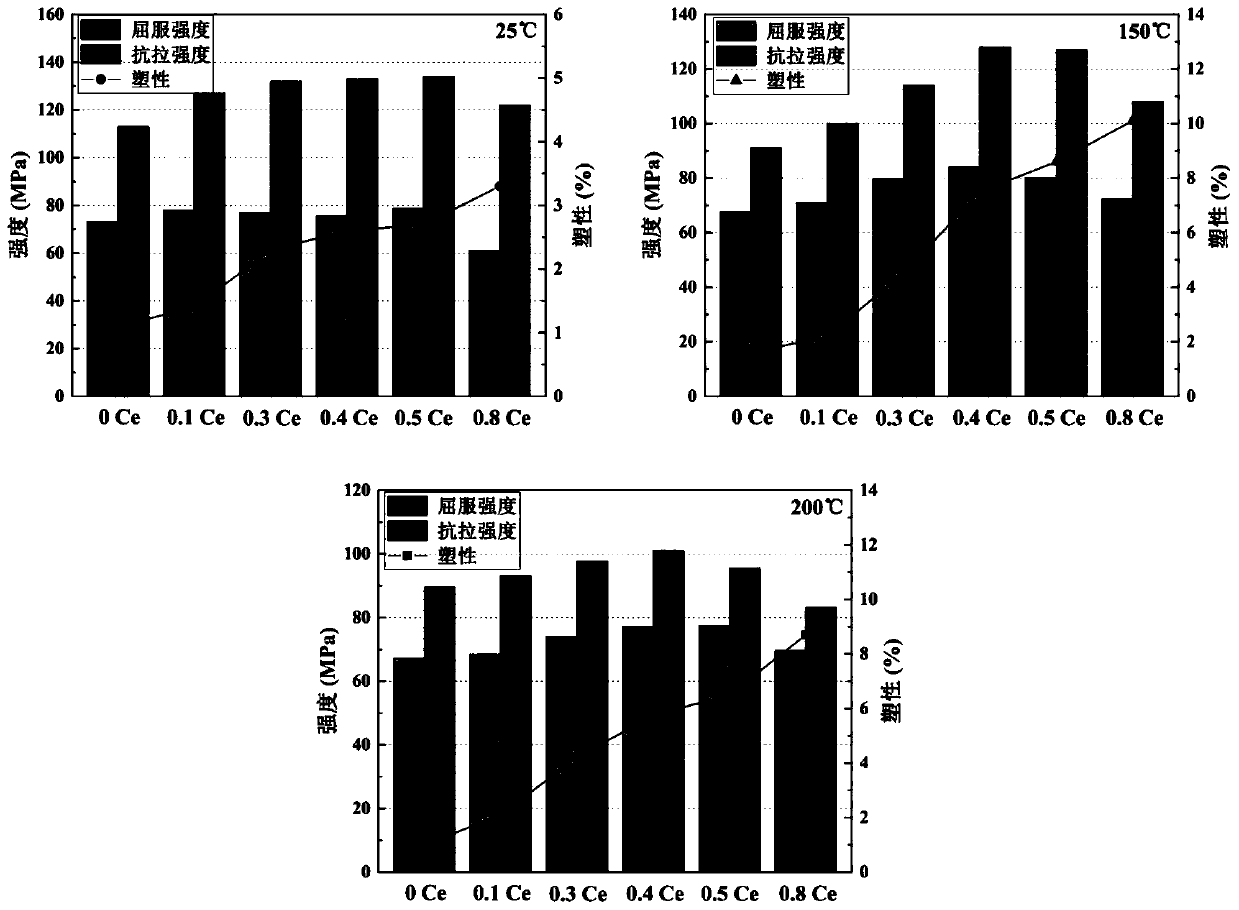

[0041] In the cast magnesium alloy of this embodiment, Chinese character-shaped Mg 2 Si phase length is about 50μm, polygonal shape Mg 2 The Si phase is about 8 μm; at room temperature (25°C), the yield strength is 76MPa, the tensile strength is 133MPa, and the plasticity is 2.6%; at 150°C, the yield strength is 85MPa, the tensile strength is 128MPa, and the plasticity is 7.5%; at 200°C, the yield strength is 78MPa, Tensile strength 101MPa, plasticity 5.8%.

Embodiment 3

[0043] Taking 10kg as an example, prepare a cast magnesium alloy according to the ratio of Mg-5Al-2Si-0.8Ce (that is, the composition content of the magnesium alloy is: 5% Al, 2% Si, 0.8% Ce, and the rest is Mg and unavoidable impurities) ; Concrete steps are with embodiment 1.

[0044] In the cast magnesium alloy of this embodiment, Chinese character-shaped Mg 2 Si phase length is about 30μm, polygonal shape Mg 2 The Si phase is about 3 μm; at room temperature (25°C), the yield strength is 61MPa, the tensile strength is 122MPa, and the plasticity is 3.3%; at 150°C, the yield strength is 72MPa, the tensile strength is 108MPa, and the plasticity is 10.1%; at 200°C, the yield strength is 70MPa, The tensile strength is 83MPa, and the plasticity is 8.7%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com