Forging method and device of titanium alloy beta forging forming on pressing machine

A titanium alloy and press technology, applied in the field of forging, can solve problems such as narrow process window, achieve fine and uniform grains, improve the degree of dislocation, and match the structure and properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Forging material: TC21, phase transition point 965°C, quantity: 5 pieces, forging size: 250×120×50 Step 1, heat forging at the phase transition point.

[0026] The bar is heated at 40° C. under β and then forged and shaped to obtain a billet 1 with a size of 130×80×210.

[0027] Step 2, heating and forging at the phase transition point.

[0028] The billet 1 was first heated at 40°C under quasi-β for 147 minutes, and kept at 15°C for 25 minutes on the beta to obtain hot billet 2. Hot billet 2 out of the furnace pressing process design forging surface 80 thick upper and lower sides, the deformation of the first pressed side is 10%, flipped 180°, the forging corresponding surface deformation is 17%. Billet 3 is obtained.

[0029] Step two, shaping.

[0030] The square billet 3 is adjusted according to the required size of the drawing, 130×80×210, to obtain a free forging at the transformation point.

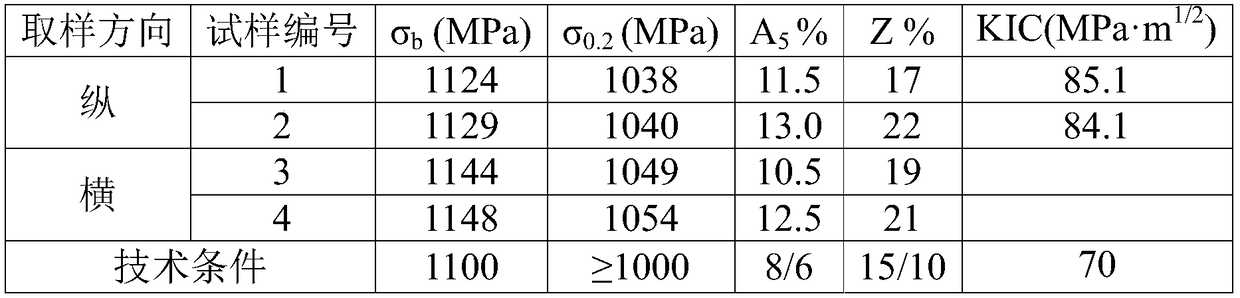

[0031] The tensile properties of table 1 embodiment 1

[0032] ...

Embodiment 2

[0035] Forging material: TC18, phase transition point 880°C, quantity: 10 pieces, forging size: 120×292×577

[0036] Step 1, heating and forging below the phase transition point.

[0037] The bar is heated at 35° C. under β and then forged and shaped to obtain a billet 1 with a size of 160×270×550.

[0038] Step 2, heating and forging at the phase transition point.

[0039] The billet 1 was first heated at 40° C. under the quasi-β for 115 minutes, and kept at 15° C. for 50 minutes on the beta to obtain the hot billet 2 . Hot billet 2 out of the furnace pressing process design forging surface 160 thick upper and lower sides, the deformation of the first pressed side is 8%, flipped 180°, the forging corresponding surface deformation is 15%. Billet 3 is obtained.

[0040] Step two, shaping.

[0041] The billet 3 is adjusted according to the required size of the drawing, 120×292×577, to obtain a free forging at the transformation point.

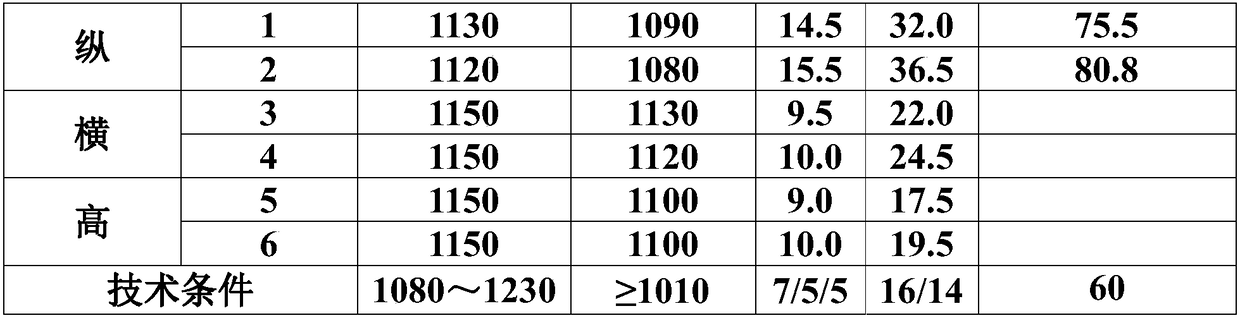

[0042] The tensile properties of tabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com