Light steel bar truss floor support plate

A technology for reinforced trusses and floor decks, which is applied to floors, structural elements, building components, etc. It can solve the problems of heavy weight of reinforced truss floor decks, easy sliding and dislocation, and insufficient adhesion, so as to reduce weight and increase stability Sexuality, the effect of reducing dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solutions in the embodiments of the present invention will be apparent from the drawings in the embodiment of the present invention.

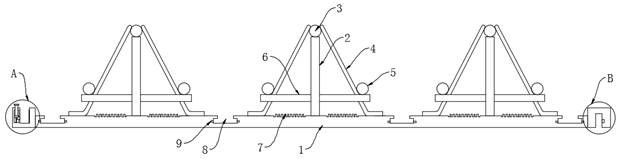

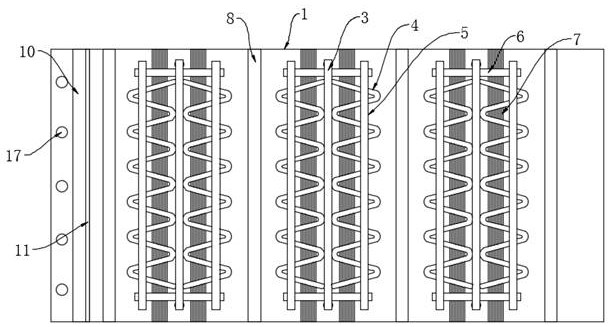

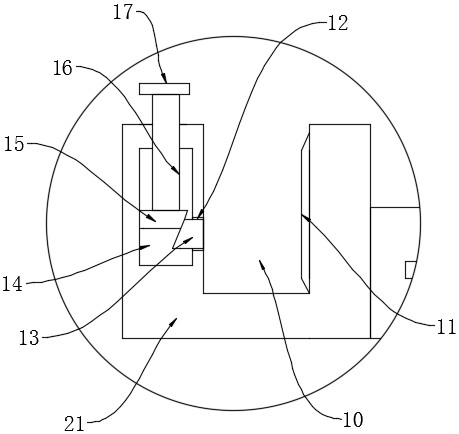

[0022] like Figure 1-5 As shown, the present invention provides a technical solution: a lightweight reinforced truss floor, including a bottom mold steel plate 1, a bottom mold steel plate 1 having a plurality of steel reinforcing components, a plurality of steel reinforcing components uniformly arranged in the bottom mold On the upper surface of the steel sheet 1, a plurality of grasping force increase mechanisms are provided, and the bottom mold steel plate 1 is welded to the U-shaped positioning seat 21 and the U-shaped positioning seat 22, and the two neighbor steel plates 1. Interpretation of the U-shaped positioning seat 22 through the U-shaped positioning seat 21.

[0023] In this embodiment, the specific: steel reinforcing assembly includes a support rearband 2, a string reinforced bar 3, a belly reinforced bar 4, a low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com