Sulfur-nitrogen co-doped graphene loaded nano-silicon three-dimensional electrode material and preparation method thereof

A three-dimensional electrode, nano-silicon technology, applied in nanotechnology, battery electrodes, nanotechnology, etc., can solve the problems of volume effect limiting practical application, low first cycle Coulomb efficiency, low conductivity of silicon materials, etc., to improve the cycle stability performance. , good cycle stability and excellent electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

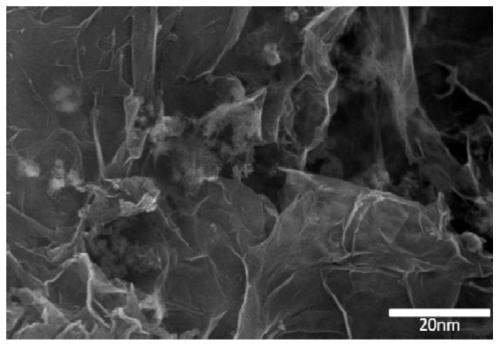

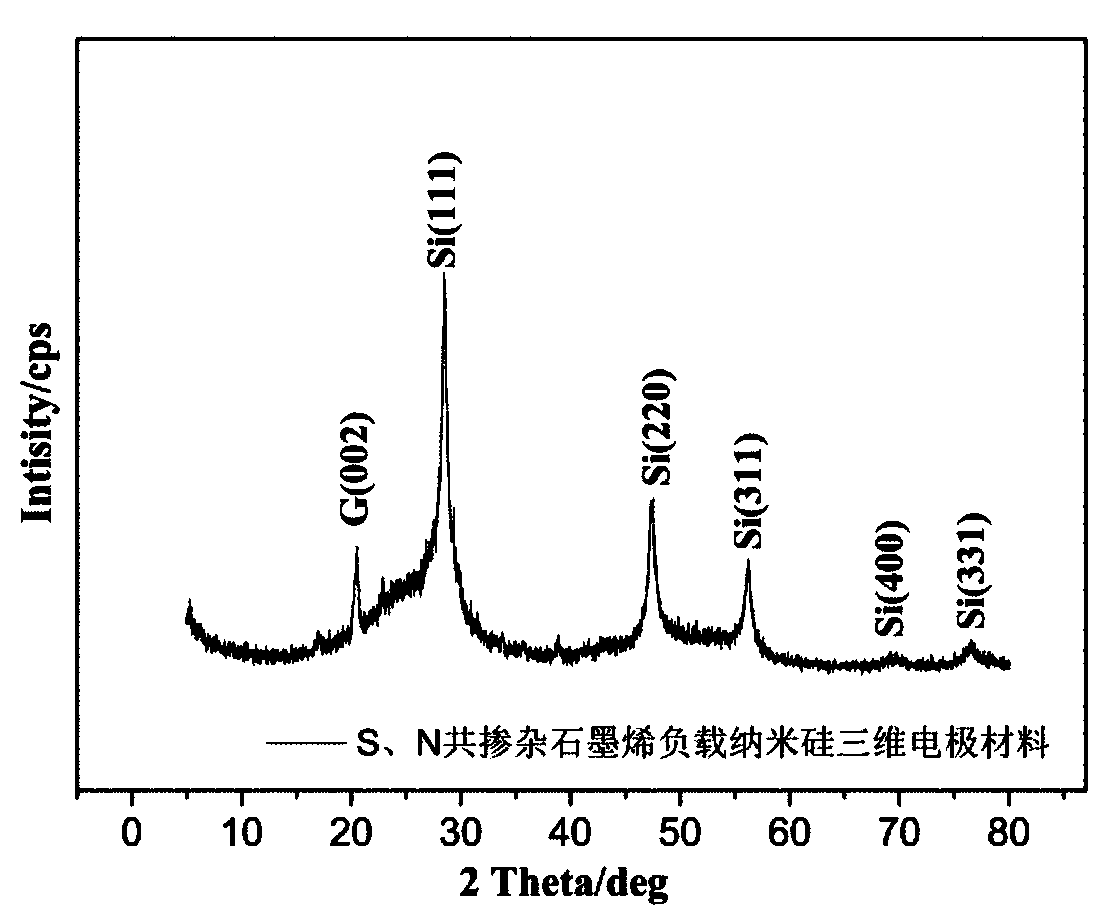

[0034] Embodiment 1: as figure 1 and figure 2 As shown, a sulfur-nitrogen co-doped graphene-loaded nano-silicon three-dimensional electrode material, which includes graphene doped with sulfur atoms and nitrogen atoms, the electrode reactivity of the doped graphene has been significantly improved, and then improved The electrochemical performance of the electrode material is improved; graphene has an intricate three-dimensional network structure, and nano-silicon is distributed between the graphene sheets, which provides a space for silicon to expand during charge and discharge, and greatly improves the cycle stability of silicon electrodes. ; The average particle size of nano-silicon is 3-10nm.

[0035] The doped sulfur atoms exist in the form of sulfide, S-S / S-C, S-O and salt-SOn-, the doped nitrogen atoms exist in three types: pyridinic-N, pyrrolic-N and Quaternary-N, and the doping of S and N atoms The amount is about 2%, and the nano-silicon accounts for about 10-20% of...

Embodiment 2

[0037] Embodiment 2: a kind of method for preparing sulfur and nitrogen co-doped graphene loaded nano-silicon three-dimensional electrode material, it comprises the following steps: (1) select raw material; (2) mix; (3) hydrothermal synthesis; (4) natural Cooling; (5) impurity removal and drying;

[0038](1) Selection of raw materials: Select the sulfur and nitrogen source doping solution, graphene oxide dispersion and nano-silica colloidal solution respectively according to the ratio of 7:1.5:1; the concentration of the sulfur and nitrogen source doping solution is about 100 mg / ml; The concentration in the graphene dispersion is about 4mg / ml; the concentration of the nano-silica colloidal solution is about 3mg / ml;

[0039] The sulfur and nitrogen source doping solution not only provides S and N atoms for electrode materials, but also can be used as a reducing agent for graphene oxide to reduce it to graphene with a three-dimensional network structure, which has the effect of ...

Embodiment 3

[0051] Embodiment 3: a kind of method for preparing sulfur and nitrogen co-doped graphene loaded nano-silicon three-dimensional electrode material, it comprises the following steps: (1) select raw material; (2) mix; (3) hydrothermal synthesis; (4) natural Cooling; (5) impurity removal and drying;

[0052] (1) Selection of raw materials: Select the sulfur and nitrogen source doping solution, graphene oxide dispersion and nano-silica colloidal solution respectively according to the ratio of 5:1.5:1; the concentration of the sulfur and nitrogen source doping solution is about 100 mg / ml; The concentration in the graphene dispersion is about 4mg / ml; the concentration of the nano-silica colloidal solution is about 3mg / ml;

[0053] The sulfur and nitrogen source doping solution not only provides S and N atoms for electrode materials, but also can be used as a reducing agent for graphene oxide to reduce it to graphene with a three-dimensional network structure, which has the effect of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com