A method for improving the strong plasticity of magnesium alloy sheet

A magnesium alloy plate, magnesium alloy technology, applied in chemical instruments and methods, metal layered products, layered products, etc., can solve the problem of increasing the cost of high-strength and high-plastic magnesium alloys, difficult to achieve industrial preparation, and high prices of rare earth elements, etc. problems, to achieve excellent strength and plasticity matching, increase processing costs, and improve the effect of plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment one, a kind of method for improving the strong plasticity of magnesium alloy plate, it comprises the following steps:

[0028] S1, the extruded AZ91 magnesium alloy plate with a thickness of 3mm in the initial state was subjected to solution treatment, the solution temperature was 410°C, and the solution time was 12h to obtain a solid solution magnesium alloy plate, denoted as SS. Part of the magnesium alloy plate in solid solution state was taken for aging treatment, the aging temperature was 180°C, and the aging time was 5h, to obtain an aged magnesium alloy plate, which was recorded as A5.

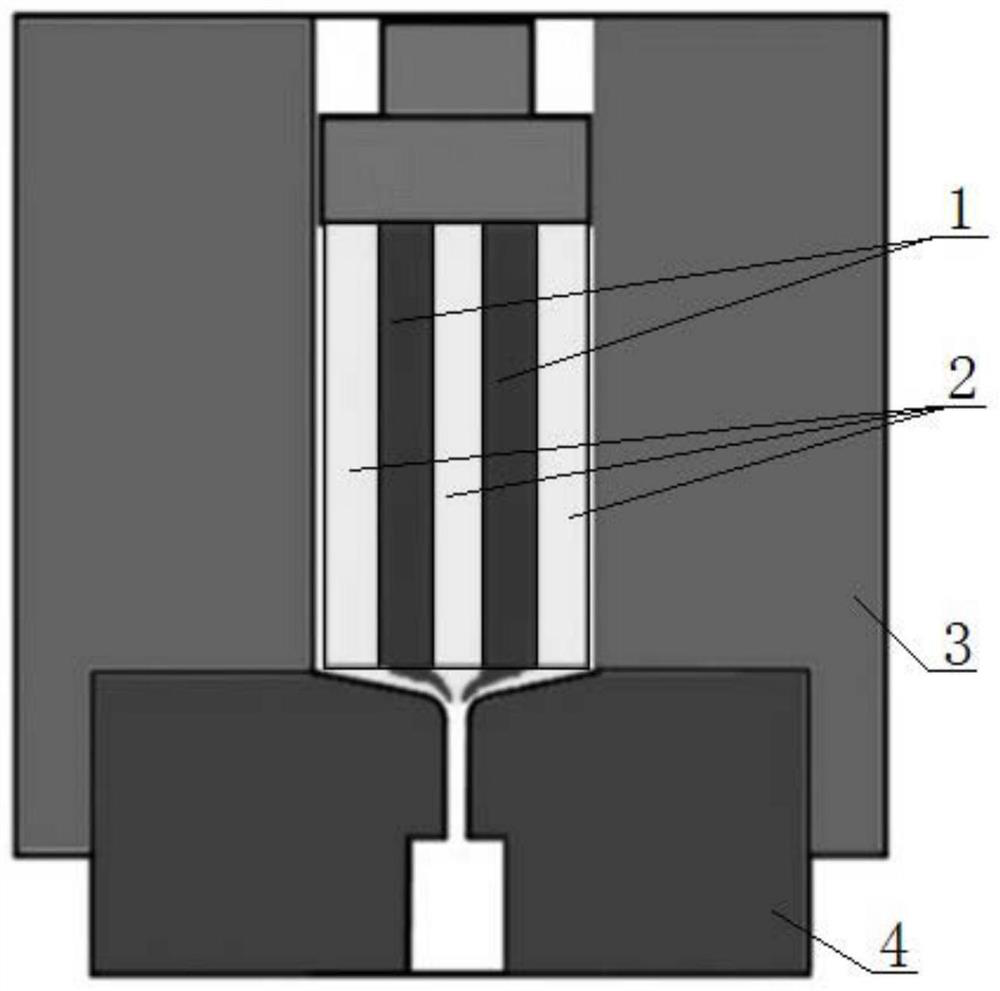

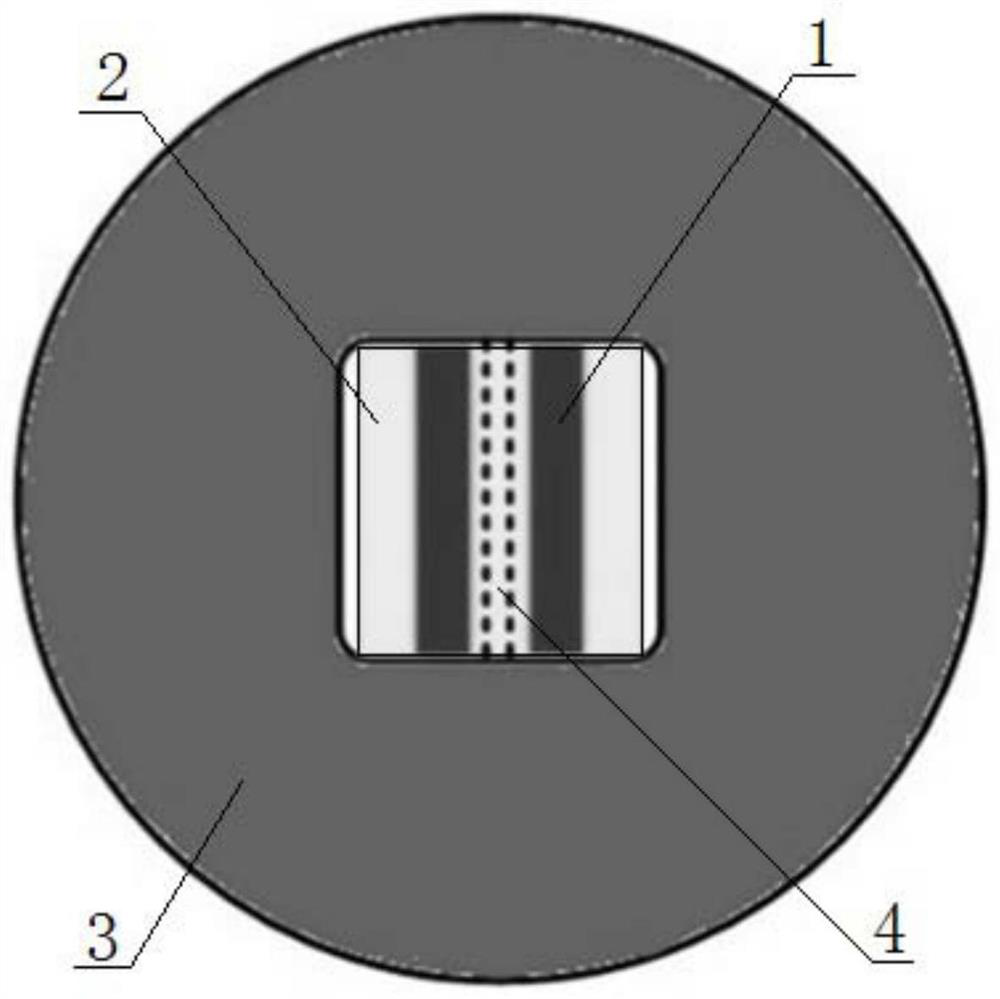

[0029] S2. Cut the solid solution magnesium alloy plate and the aging state magnesium alloy plate into small plates with a size of 35mm×15mm×1.5mm, two solid solution magnesium alloy plates and three aging state magnesium alloy plates, respectively surface Grinding and degreasing treatment. see figure 1 with figure 2 The solid solution magnesium alloy plate 1 and t...

Embodiment 2

[0031] Embodiment 2, a method for improving the strong plasticity of magnesium alloy sheet material, the magnesium alloy sheet material used, the solution treatment process and the extrusion compounding process are all the same as the embodiment 1, except that the aging treatment process parameters are different, and the aging temperature is 180 ° C , the aging time is 10h, the yield strength of the finished product at room temperature is 185Mpa, the tensile strength is 386Mpa, and the elongation at break is 19.6%.

Embodiment 3

[0032] Embodiment 3, a method for improving the strong plasticity of magnesium alloy sheet material, the magnesium alloy sheet material used, the solution treatment process and the extrusion compounding process are all the same as the embodiment 1, except that the aging treatment process parameters are different, and the aging temperature is 180 ° C , the aging time is 20h, the yield strength of the finished product at room temperature is 173Mpa, the tensile strength is 379Mpa, and the elongation at break is 19.5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com