Device and method for ultrasonically refining magnesium alloy under vacuum conditions

A technology of vacuum condition and vacuuming device is applied in the field of refining device of magnesium alloy liquid, which can solve the problems of affecting the quality of magnesium alloy, the effect is not obvious, and the strength and plasticity are reduced, so as to achieve low operating cost, improve refining effect, and improve strength. and plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

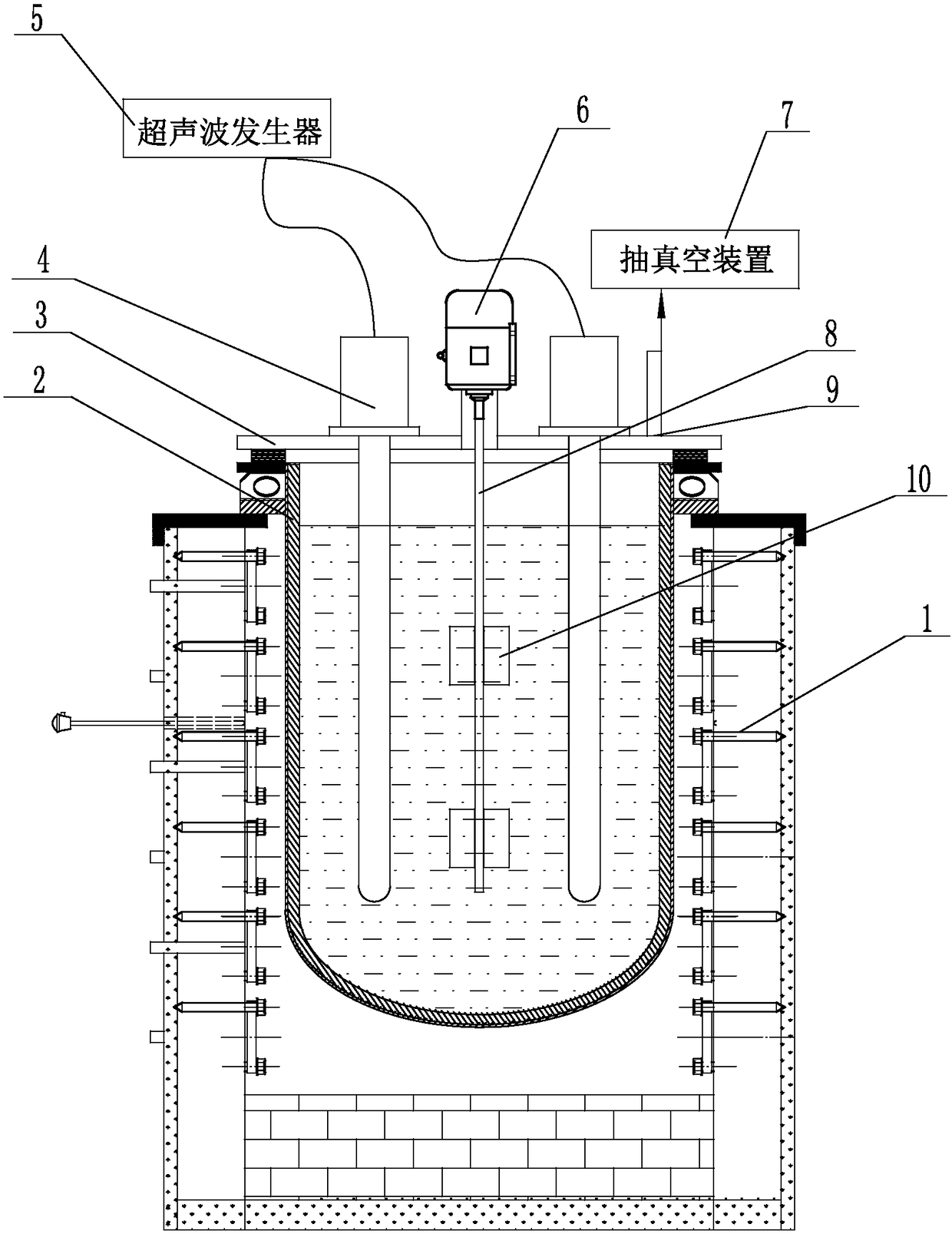

[0023] Embodiments of the present invention are further described below in conjunction with accompanying drawings:

[0024] Such as figure 1 As shown, the device for ultrasonically refining magnesium alloys under vacuum conditions according to the present invention includes an electric furnace 1, a crucible 2 is installed in the electric furnace 1, a sealing cover plate 3 is arranged on the top of the crucible 2, and an acoustic wave vibration part 4 is arranged in the crucible 2 , the upper part of the sound wave vibration part 4 is supported and fixed by the sealing cover plate 3, the sound wave vibration part 4 is connected to the ultrasonic generator 5, the sealing cover plate 3 is also provided with an agitator 6, and the stirring shaft 8 and the stirring paddle 10 of the agitator 6 extend into the In the crucible 2 , a vacuum hole 9 is also provided on the sealing cover plate 3 , and the vacuum hole 9 is connected to the vacuum device 7 .

[0025] The four acoustic vibr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com