4D printing method of in-situ regulation of functional characteristics of nickel-titanium alloy and application

A technology of nickel-titanium alloy and functional characteristics, applied in the field of additive manufacturing, can solve the problems of high cost, difficult to control components, single composition of nickel-titanium alloy, etc., and achieve the effect of uniform performance and rapid manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

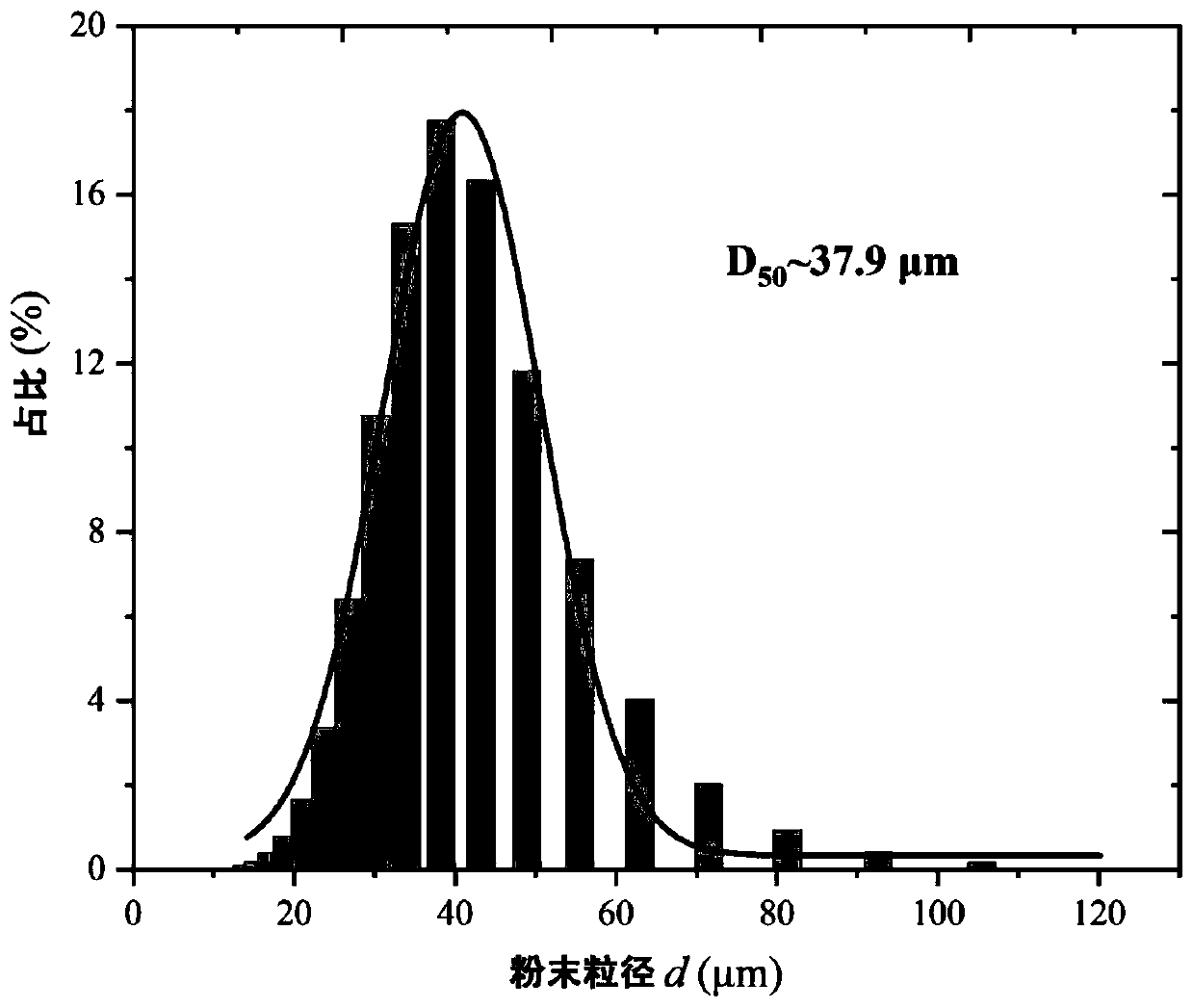

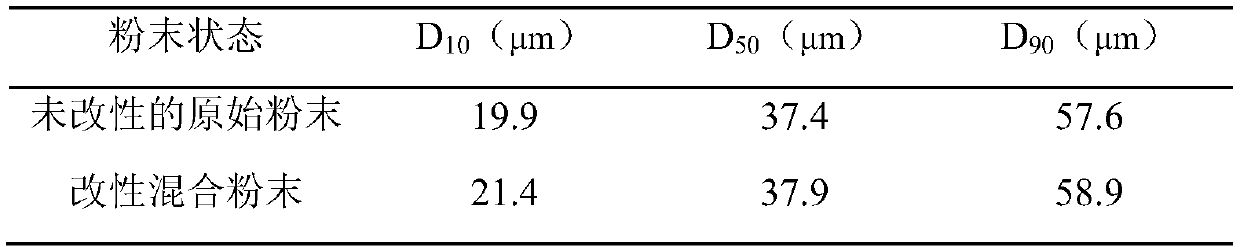

[0027] 1. Atomized powder making. Dosing is carried out according to the following atomic ratio of nickel and titanium: Ti 50.6 at.%, Ni 49.4 at.%. Nitinol rods are smelted under vacuum conditions. The rod is atomized, the obtained raw powder is collected, and screened to control the particle size of the target powder within the range of 15-53 μm.

[0028] 2. Powder modification. The nickel-titanium alloy powder (mass m 1 ) for discharge treatment. The control parameters are: voltage 130V, current 1.4A, electrode rotation speed 800r / min, the duration of each discharge treatment is 0.5h, the interval between two adjacent discharge treatments is 30min, and the number of discharge plasma treatments is 6 times. Subsequently, nickel powder with a particle size of 100 nm was added to the nickel-titanium alloy powder treated by discharge plasma, and the mass m 2 , control m 1 :m 2 =30:1, so that Ti:Ni=49.1:50.9(at.%) in the mixed powder, adjust the electrode speed to 600r / min,...

Embodiment 2

[0036] 1. Milling. Dosing according to the following atomic ratio of nickel and titanium: Ti 60 at.%, Ni 40 at.%. Nitinol rods are smelted under vacuum conditions. The rod is atomized, the obtained raw powder is collected, and screened to control the particle size of the target powder within the range of 15-53 μm.

[0037] 2. Powder modification. The nickel-titanium alloy powder (mass m 1 ) for discharge treatment. The control parameters are: voltage 120V, current control at 1A, electrode rotation speed 1000r / min, duration of each discharge treatment is 1h, interval between two adjacent discharge treatments is 45min, and discharge treatment times are 3 times. Add nickel powder with a particle size of 500nm after the original powder treatment, adding mass m 2 , control m 1 :m 2 =4.91:1, so that the atomic ratio of titanium to nickel in the mixed powder is Ti 49.2Ni 50.8 (at.%), adjust the electrode speed to 700r / min, and control the current at 1.8A, and then continue to ...

Embodiment 3

[0041] 1. Milling. Dosing according to the following atomic ratio of nickel and titanium: Ti 50 at.%, Ni 50 at.%. Nitinol rods are smelted under vacuum conditions. The rod is atomized, the obtained raw powder is collected, and screened to control the particle size of the target powder within the range of 15-53 μm.

[0042] 2. Powder modification. The nickel-titanium alloy powder (mass m 1 ) for discharge treatment. The control parameters are: voltage 125V, current control at 1.4A, electrode rotation speed 800r / min, duration of each discharge treatment is 1.5h, interval between two adjacent discharge treatments is 30min, and discharge treatment times are 3 times. Add nickel powder with a particle size of 300nm after the original powder treatment, adding mass m 2 , control m 1 :m 2 =44.4:1, so that the atomic ratio of titanium to nickel in the mixed powder is Ti 49Ni 51 (at.%), adjust the electrode speed to 500r / min, and control the current at 1.8A, and then continue to d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com