Metallic bottle can and method for manufacturing same

A manufacturing method and technology of bottles and cans, applied in the field of metal bottles and cans and its manufacturing, can solve the problems of increased production costs, etc., and achieve the effects of small opening torque, excellent cover openability, and reduced heating frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0078] [Measurement]

[0079] (measure MEK extraction rate)

[0080] The film was removed from the inner surface of the obtained jar by using concentrated sulfuric acid. Then rinse the jar with water and allow the jar to dry. The threaded portion of the bottle and can was cut into a test piece of 30 mm×30 mm, and the test piece was weighed (A). Next, the weighed test piece was immersed in MEK (methyl ethyl ketone), and then boiled and refluxed for 1 hour. After reflow, the test piece was washed twice with virgin MEK, dried and then weighed (B). The finish varnish layer was removed from the already weighed test pieces by using concentrated sulfuric acid. Then, the test piece was washed with water, and dried and weighed (C). Based on the weighed value, the extraction rate was calculated according to the following formula.

[0081] MEK extraction rate (% calculated by mass)=100×(A-B) / (A-C)

[0082] Among them, A is the quality of the test piece before extraction,

[0083] B...

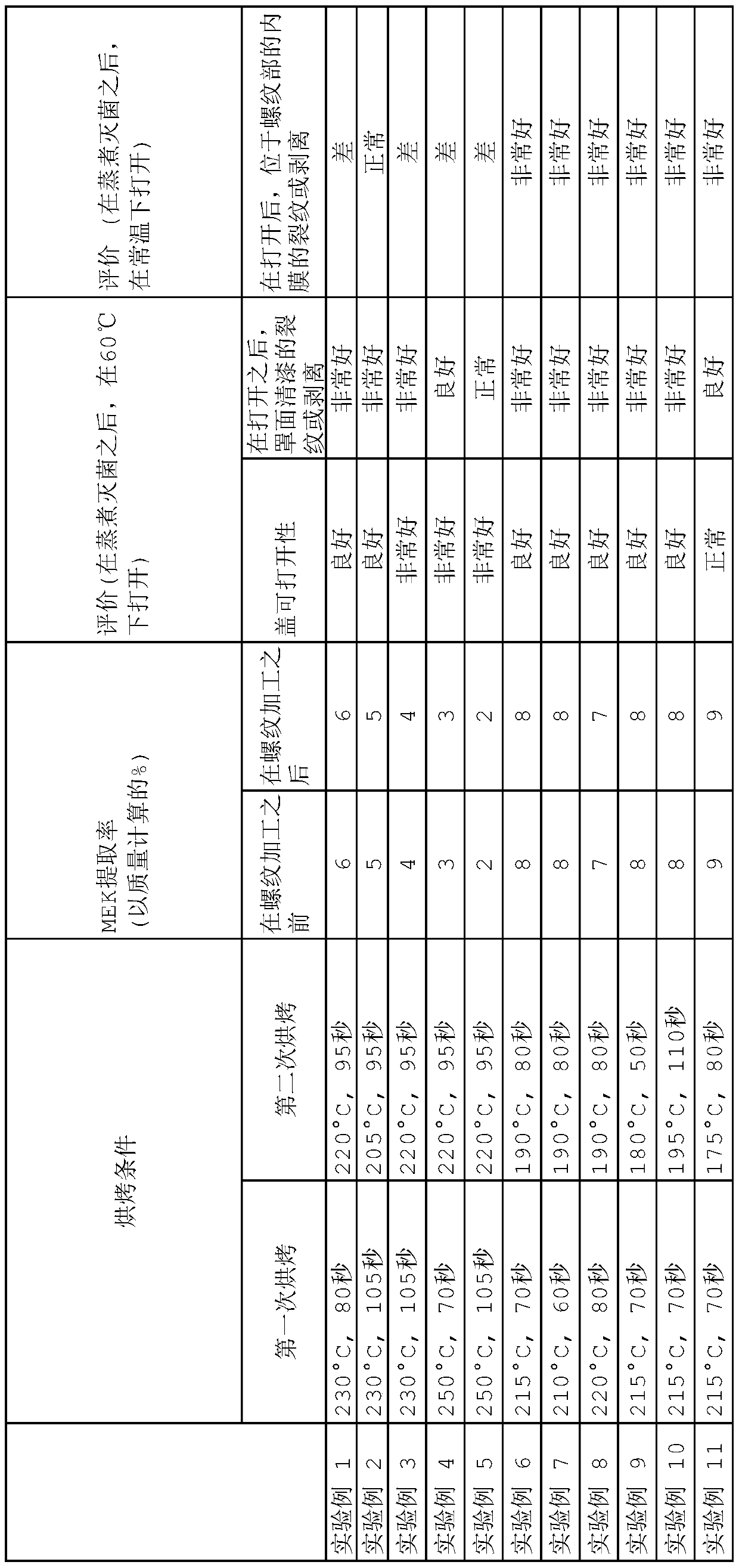

experiment example 1

[0113] A circular body was punched out from an aluminum alloy sheet JIS3104 with a thickness of 0.38 mm. The round blank is drawn and then drawn and thinned to obtain a bottomed cylinder. The opening of the bottomed cylindrical body was cut out to obtain a can body. Next, the can body is washed, dried, and printed on the side surface of the can body (except for the area that will become the mouth when the can body is formed into a bottle). In addition, a finish varnish containing a mixed resin selectively containing polyester resin, epoxy resin, and amino resin as a matrix resin was applied to the entire side surface of the can body including the region to be the mouth so that at the The film thickness will become 4 μm after the second bake. Next, a first bake was performed at 230° C. for 80 seconds in a bulk furnace. Thereafter, the inner surface of the can body was sprayed with the paint for forming the inner surface, and a second bake was performed on the inner surface o...

experiment example 2

[0115] Filled jars were prepared in the same manner as in Experimental Example 1, but with a first bake at 230°C for 105 seconds and a second bake at 205°C for 95 seconds. Measurements and evaluations were carried out on the filled bottles to obtain the results shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com