Composite ceramic and preparation method and application thereof

A technology of composite ceramics and composite ceramics, applied in the field of ceramic materials, can solve the problems of reducing thermal conductivity and mechanical strength of composite ceramics, deterioration of thermal conductivity and mechanical properties of composite ceramics, and reduction of sintering activity of composite ceramics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] A preparation method of composite ceramics, comprising the following steps:

[0040] a) mixing the coated first-phase ceramic composite powder with the coated second-phase ceramic composite powder, and granulating to obtain a composite ceramic powder;

[0041] b) sequentially molding and sintering the composite ceramic powder to obtain a composite ceramic;

[0042] Wherein, the coated first phase ceramic composite powder includes the first phase ceramic powder and the rare earth metal oxide and / or alkaline earth metal oxide coated on the surface of the first phase ceramic powder, and the coated second phase ceramic composite powder The body includes the second phase ceramic powder and the rare earth metal oxide and / or alkaline earth metal oxide coated on the surface of the second phase ceramic powder.

[0043] In the present invention, rare earth metal oxides and / or alkaline earth metal oxides are coated on the surface of the first phase ceramic powder and the second p...

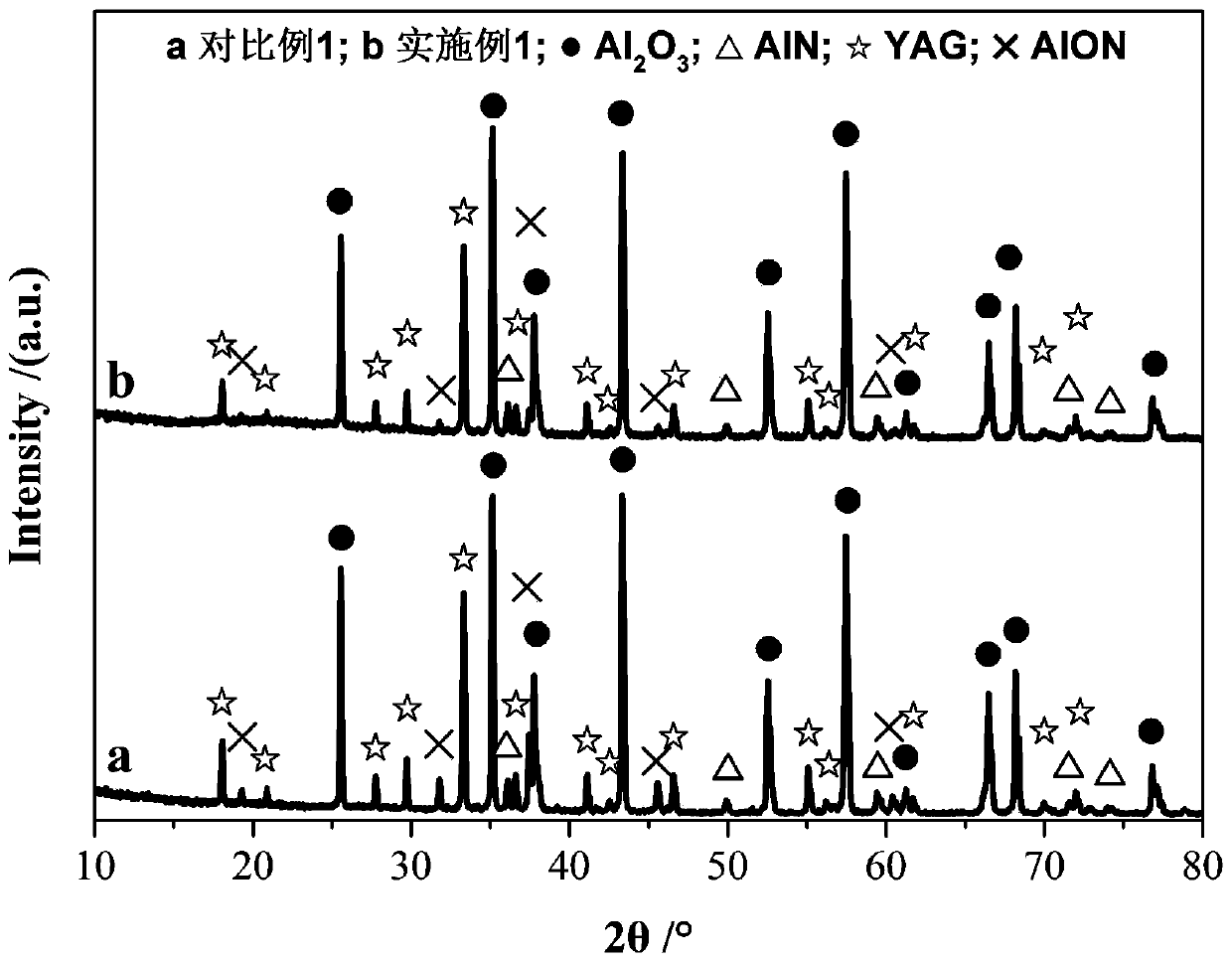

Embodiment 1

[0092] This embodiment provides the first preparation method of alumina-aluminum nitride composite ceramics, comprising the following steps:

[0093] 1. Weigh 12.17 parts by mass of yttrium nitrate, dissolve it in absolute ethanol, and prepare Y 3+ Concentration is the ethanol solution (coating solution) of the yttrium nitrate of 0.15mol / L; And the ethanol solution (precipitant solution) of the ethylenediamine of preparation pH value is 13;

[0094] 2. Weigh 95 parts by mass of alumina ceramic powder and 0.5 parts by mass of PEG 2000, add them to the coating solution, ultrasonically disperse for 1 hour, and use a magnetic stirrer to mechanically disperse at a speed of 100r / min for 1 hour to prepare alumina Ceramic slurry; then while mechanically dispersing (magnetic stirrer, 100r / min) the alumina ceramic slurry, slowly drop the precipitant solution to it until the pH of the suspension system is 9.5, stop dropping the precipitant solution , after continuing to mechanically dis...

Embodiment 2

[0100] This embodiment provides the second preparation method of alumina-aluminum nitride composite ceramics, comprising the following steps:

[0101] 1. Weigh 11.10 parts by mass of magnesium nitrate, dissolve it in deionized water, and prepare Mg 2+ Concentration is the aqueous solution (coating solution) of magnesium nitrate of 0.01mol / L; And the ammonia solution (precipitant solution) that preparation pH value is 11; Ammonium acrylate was added to the coating solution and dispersed by ball milling for 4 hours to prepare alumina ceramic slurry; then, while mechanically dispersing (paddle mixer, 300r / min) the alumina ceramic slurry, slowly dropwise dropwise precipitate When the pH of the suspension system reaches 8.5, stop adding the precipitant solution dropwise, continue the mechanical dispersion for 6 hours, and then dry it in an oven at 120°C for 4 hours; then use a muffle furnace to calcinate at 350°C for 6 hours to obtain a coating Alumina ceramic composite powder.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity at room temperature | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

| Thermal conductivity at room temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com