A kind of copper nitrogen iron antiperovskite structure room temperature soft magnetic thin film material and its preparation method

A technology of anti-perovskite and soft magnetic thin films, applied in the direction of magnetism of inorganic materials, can solve the problems of high preparation cost, inability to obtain copper nitrogen iron metal nitride room temperature soft magnetic thin film materials, and inability to obtain large-area thin films, etc., to achieve Less equipment, good for large-scale industrial production, wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) Weigh copper nitrate and ferric nitrate according to the molar ratio of copper and iron being 1:3, and simultaneously add copper nitrate and ferric nitrate to the ethylene glycol methyl ether solution at 70°C and stir until it is completely dissolved, Stir at room temperature for 6 h to obtain a precursor solution with a concentration of 0.2 mol / L.

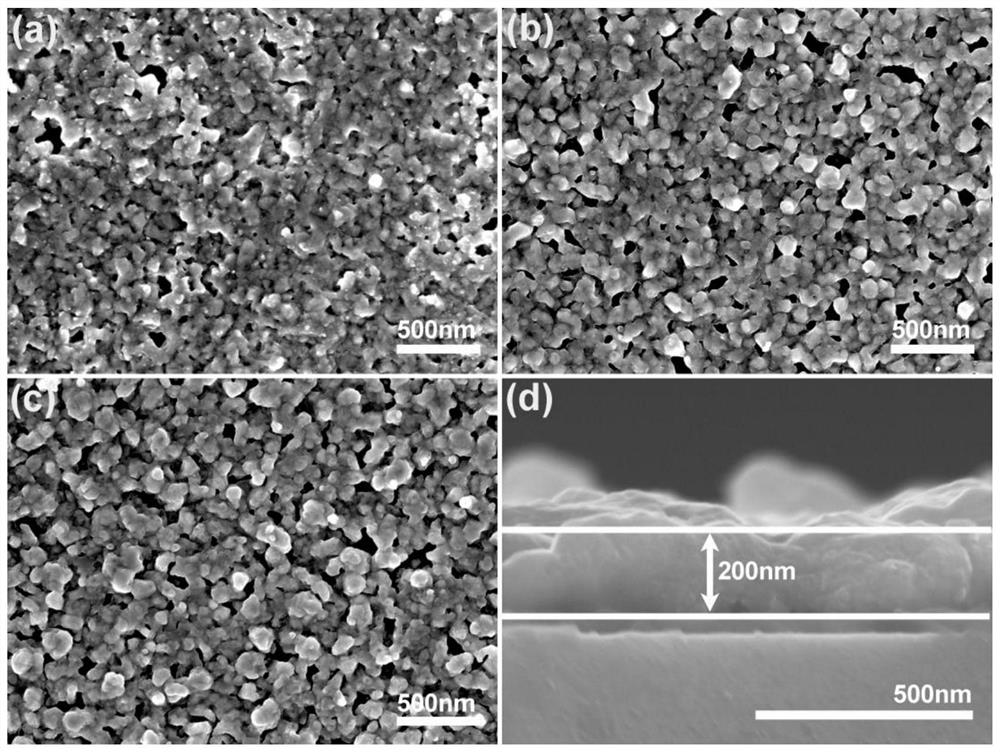

[0029] (2) First apply the precursor solution to the substrate, wherein the coating is spin coating, the substrate is a semiconductor substrate silicon wafer, the rotational speed during spin coating is 4000r / min, the time is 30s, and heated at 150°C for 5min, The substrate covered with the gel film was obtained, and then the substrate covered with the gel film was pyrolyzed at 350° C. for 12 minutes to obtain the substrate covered with the thin film.

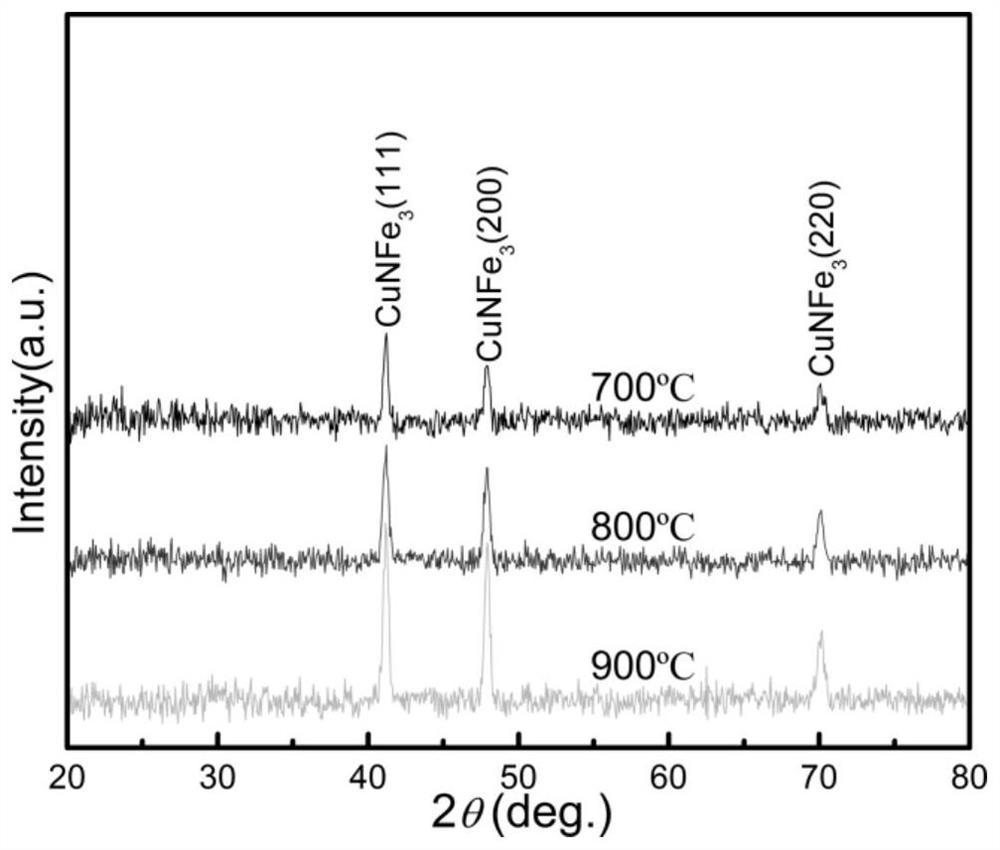

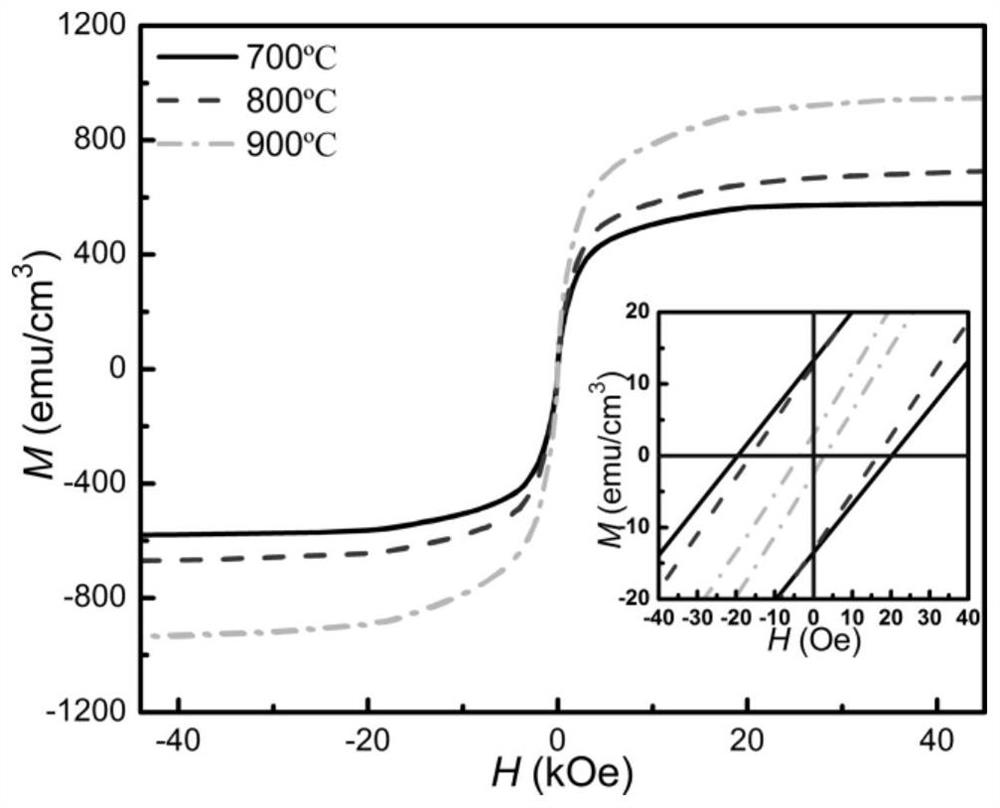

[0030] (3) After repeating the number of times of step 2 10 times, first place the obtained substrate covered with multi-layer film in an air atmosphere at 850° C. for 1...

Embodiment 2

[0032] (1) According to the molar ratio of copper and iron being 1:3, weigh copper nitrate and ferric nitrate, add copper nitrate and ferric nitrate to the ethylene glycol methyl ether solution at 75°C and stir until it is completely dissolved, Stir at room temperature for 6.5 h to obtain a precursor solution with a concentration of 0.3 mol / L.

[0033] (2) Apply the precursor solution to the substrate first, wherein the coating is spin coating, the substrate is a semiconductor substrate silicon wafer, the rotational speed during spin coating is 5000r / min, the time is 20s, and the substrate is a semiconductor substrate silicon wafer, Heating at 170° C. for 4 minutes to obtain a substrate covered with a gel film, and then placing the substrate covered with a gel film at 370° C. for 11 minutes to obtain a substrate covered with a thin film.

[0034] (3) After repeating the number of times of step 2 for 9 times, first place the obtained substrate covered with multi-layer film in a...

Embodiment 3

[0036] (1) According to the molar ratio of copper and iron being 1:3, weigh copper nitrate and ferric nitrate, and simultaneously add copper nitrate and ferric nitrate to the ethylene glycol methyl ether solution at 80°C and stir until it is completely dissolved, Stir at room temperature for 7 hours to obtain a precursor solution with a concentration of 0.4 mol / L.

[0037] (2) Apply the precursor solution to the substrate first, wherein the coating is spin coating, the substrate is a semiconductor substrate silicon wafer, the rotational speed during spin coating is 6000r / min, the time is 10s, and the substrate is a semiconductor substrate silicon wafer, Heating at 200° C. for 3 minutes to obtain a substrate covered with a gel film, and then placing the substrate covered with a gel film at 400° C. for 10 minutes to obtain a substrate covered with a thin film.

[0038] (3) After repeating the number of times of step 2 for 8 times, first place the obtained substrate covered with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com