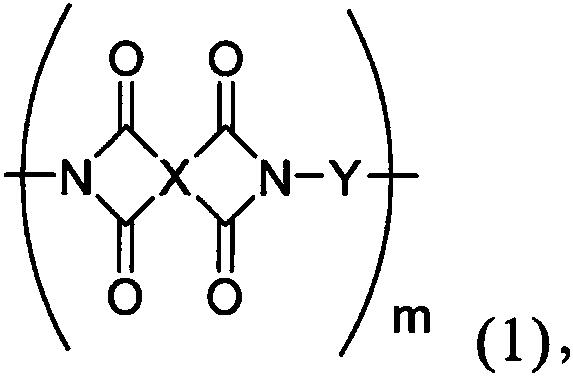

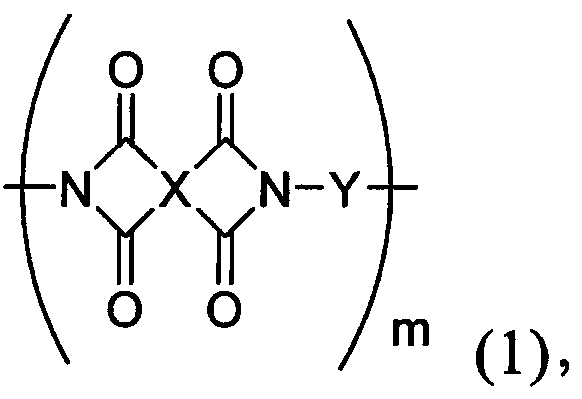

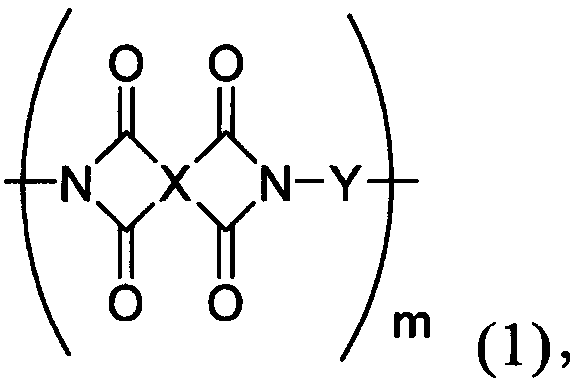

Photosensitive polyimide resin composition and polyimide film thereof

A technology of polyimide resin and resin composition, applied in the field of photosensitive resin composition, can solve the problem of limited application, low transmittance of photosensitive polyimide, unsuitable for transparent protective layer or insulation of liquid crystal display device layers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] The preparation of the interlayer insulating film and the protective film of the present invention can be carried out by coating methods such as spin coating or casting coating, and the photosensitive polyimide resin composition is coated on the substrate, and then prebaked ( The prebake) method removes the solvent to form a pre-baked coating film. Among them, the conditions of the pre-baking vary according to the types and compounding ratios of the components, and are usually carried out at a temperature of 80-120° C. for 5-15 minutes. After pre-baking, the coating film is exposed under a photomask. The light used for exposure is preferably ultraviolet light such as g-line, h-line, i-line, etc., and the ultraviolet irradiation device can be (ultra) high pressure mercury lamp and metal halide lamp. Then immerse in a developing solution at a temperature of 20-40° C. for 1-2 minutes to remove unnecessary parts and form a specific pattern. Examples of the developer inclu...

Synthetic example 1

[0049] Synthesis Example 1: Preparation of Photosensitive Polyimide

[0050] 62.12 g (0.194 mole) of 2,2'-bis(trifluoromethyl)benzidine (TFMB) and 500 g of DMAc were placed in a three-necked flask. After stirring at 30° C. until completely dissolved, 84.86 g (0.200 mole) of propylene glycol bis(trimellitic anhydride) (TMPG) was added, and then stirred continuously and reacted at 25° C. for 24 hours to obtain a polyamic acid solution. Then, 23.00 g (0.290 mole) of pyridine and 59.4 g (0.582 mole) of acetic anhydride were added, and the reaction was continued at 25° C. for 24 hours while stirring. After the reaction, polyimide was precipitated in 5 liters of water, and the mixture of water and polyimide was stirred at a speed of 5000 rpm for 15 minutes. The polyimide was collected by filtration, poured into 4 liters of water again, stirred for 30 minutes, and filtered again. Then, the obtained polyimide was dried at 45 degreeC for 3 days under reduced pressure, and the dried p...

Synthetic example 2

[0051] Synthesis example 2: Preparation of polyamic acid ester with methacrylate group

[0052] [Propylene glycol bis(trimellitic anhydride) (TMPG), 2,2′-bis(trifluoromethyl)benzidine (TFMB) and 2-hydroxyethyl methacrylate (HEMA) polyamides having methacrylate groups Synthesis of ester (D3)]

[0053] In a four-necked flask, 16.97 g (40.0 mmol) of propylene glycol bis(trimellitic anhydride) (TMPG), 10.94 g (84.0 mmol) of 2-hydroxyethyl methacrylate (HEMA), 0.04 g (0.4 mmol) ) of hydroquinone, 3.16 g (84.0 mmol) of pyridine, and 80 mL of tetrahydrofuran were sequentially added, stirred at 50° C. for 3 hours, and a transparent solution was obtained after a few minutes from the start of heating. The reaction mixture was cooled to room temperature. Then, the reaction mixture was cooled to -10°C, and 11.9 g (100.0 mmol) of thionyl chloride was added over 10 minutes while maintaining the temperature at -10°C±4°C. During the addition of thionyl chloride, the viscosity increased. A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com