High-temperature liquid metal lithium battery and preparation method thereof

A liquid metal, lithium battery technology, applied in the manufacture of electrolyte batteries, battery electrodes, secondary batteries, etc., can solve the problems of high battery operating temperature, increased material corrosion, battery sealing, and difficulty in safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

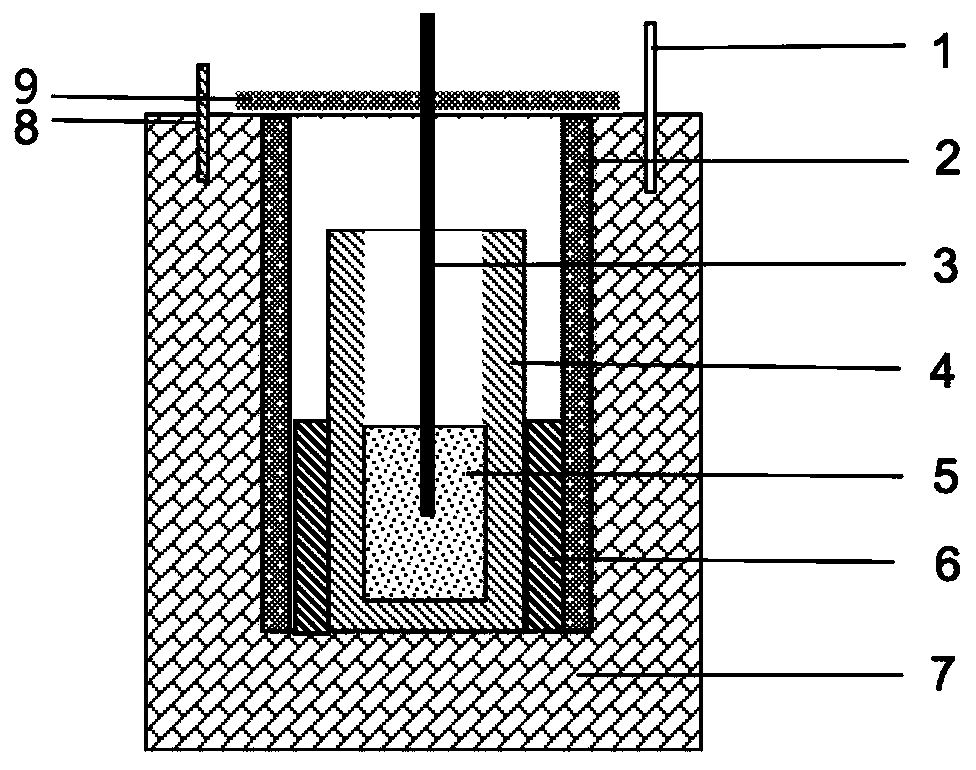

[0054] The present invention also provides a method for preparing a high-temperature liquid metal lithium battery described in the above technical solution, comprising the following steps:

[0055] In the glove box, put the alumina crucible into the graphite crucible to complete the basic assembly of the shell container;

[0056] In the glove box, put the LAGP type solid electrolyte shell into the alumina crucible, add Bi-Sn alloy between the LAGP type solid electrolyte shell and the alumina crucible, and put metal Li into the LAGP type solid state electrolyte case, insert the negative current collector, and cover the aluminum oxide crucible to obtain the high-temperature liquid metal lithium battery.

[0057] In the present invention, the alumina crucible and the graphite crucible are preferably wiped with alcohol and washed with water, and then placed in an oven for 8-10 hours before being used.

[0058] In order to further illustrate the present invention, the high-tempera...

Embodiment 1

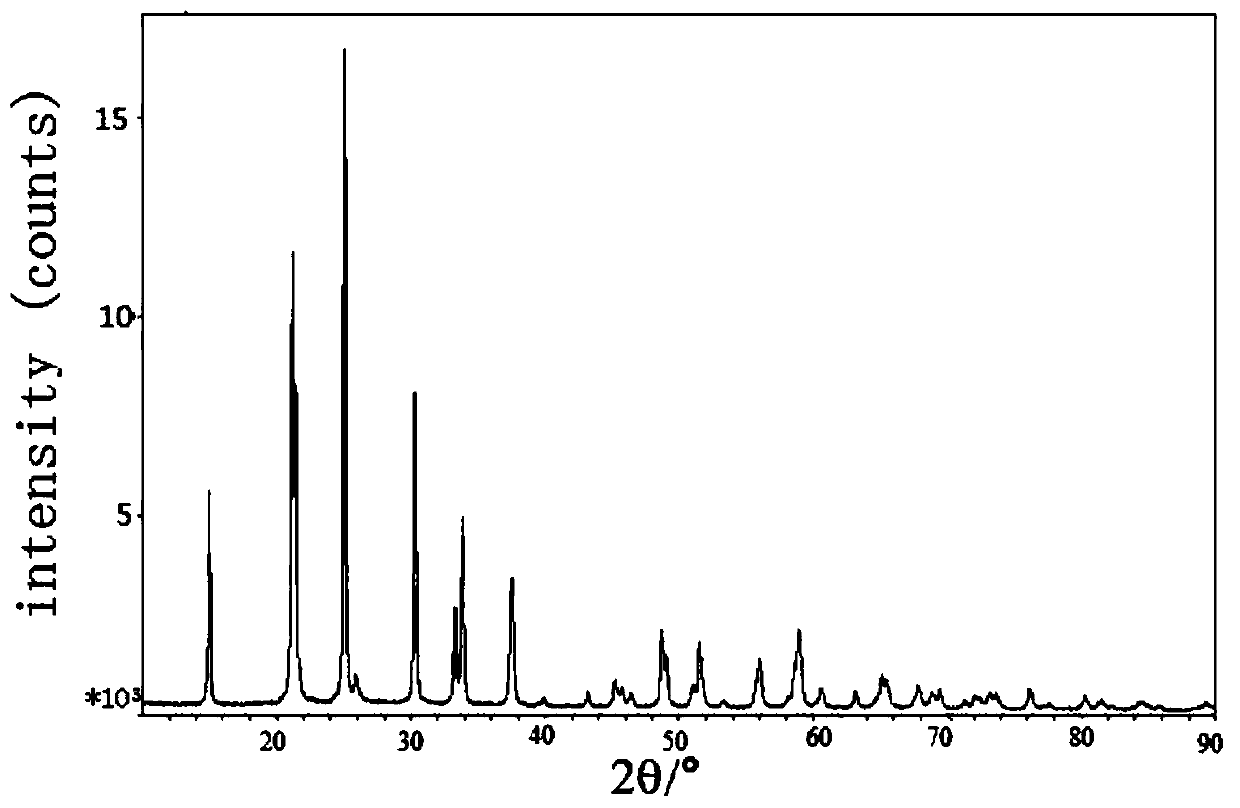

[0060] Powder: the mole fraction ratio is 14.6% LiCO 3 , 4.2% Al 2 o 3 , 2.0%In 2 o 3 , 25.3% GeO 2 and 53.9% NH 4 h 2 PO 4 Make a ratio. Put the mixed powder into a ball mill for grinding for 1 hour. Then put the uniformly ground powder in a platinum crucible, place it in a muffle furnace, raise it from 25°C to 700°C at a speed of 5°C / min, and keep the temperature constant for 2h. Then increase to 1500°C at a rate of 5°C / min and keep the temperature constant for 2h. Take the platinum crucible out of the muffle furnace, add the powder into distilled water, then put the obtained glassy substance into a tube furnace and raise the temperature to 850°C at a rate of 1°C / min, and keep the temperature for 10h. After natural cooling, the obtained glass ceramics are taken out, put into a ball mill for ball milling, and finally a powdery product is obtained. Carry out XRD pattern analysis to powdery product, the result is as follows figure 2 As shown, it can be seen from th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com