Method for preparing platinum nitrate solution by synergism of molten salt method and ultrasound

A technology of platinum nitrate and molten salt method, applied in chemical instruments and methods, ruthenium/rhodium/palladium/osmium/iridium/platinum compounds, inorganic chemistry, etc. It can solve the problems of environmental pollution and other problems, so as to achieve the effect of easy control of the preparation process, simple process flow and easy industrialization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

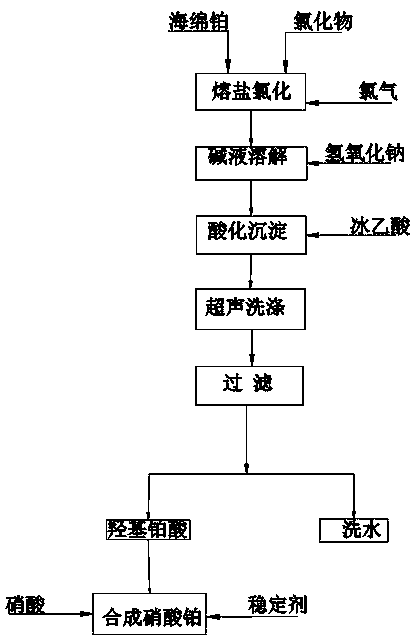

[0025] Embodiment 1: The method for preparing platinum nitrate solution in cooperation with ultrasound of this molten salt method, such as figure 1 As shown, the specific steps are as follows:

[0026] (1) Chlorination of sponge platinum medium-temperature molten salt to generate sodium chloroplatinate: mix 300 g of commercially available platinum sponge powder with a purity greater than 99.95% and 900 g of industrial sodium chloride at a mass ratio of 1:3, and then mix the mixed material Put it into a quartz boat and put it into a tube furnace to heat to 450°C, then introduce chlorine gas at a flow rate of 65mL / min, turn off the chlorine gas after 4 hours, cool to room temperature, and take it out to obtain sodium chloroplatinate powder;

[0027] (2) Hydrolysis to generate sodium hexahydroxyplatinate: Dissolve 750g of analytically pure sodium hydroxide in 5000mL of ultrapure water to prepare a sodium hydroxide solution with a mass fraction of 13.04%. The mass ratio of sodium...

Embodiment 2

[0032] Embodiment 2: the method for the ultrasonic coordinated preparation of platinum nitrate solution by the molten salt method, such as figure 1 As shown, the specific steps are as follows:

[0033] (1) Chlorination of sponge platinum medium-temperature molten salt to generate sodium chloroplatinate: mix 1000g of commercially available platinum sponge powder with a purity greater than 99.95% and 2500g of industrial sodium chloride at a mass ratio of 1:2.5, and then mix the mixed material Put in a quartz boat and put it into a tube furnace to heat to 580°C, then introduce chlorine gas at a flow rate of 85mL / min, and then turn off the chlorine gas after feeding chlorine gas for 3 hours, and take it out after cooling to room temperature to obtain sodium chloroplatinate powder;

[0034](2) Hydrolysis to generate sodium hexahydroxyplatinate: Dissolve 2000g of analytically pure sodium hydroxide in 25000mL of ultrapure water to prepare a sodium hydroxide solution with a mass frac...

Embodiment 3

[0039] Embodiment 3: the method for preparing platinum nitrate solution in cooperation with the molten salt method ultrasonically, such as figure 1 As shown, the specific steps are as follows:

[0040] (1) Chlorination of sponge platinum medium-temperature molten salt to generate sodium chloroplatinate: mix 1000g of commercially available platinum sponge powder with a purity greater than 99.95% and 1000g of industrial sodium chloride at a mass ratio of 1:1, and then mix the mixed material Put in a quartz boat and put it into a tube furnace to heat to 300°C, then introduce chlorine gas at a flow rate of 75mL / min, and then cut off the chlorine gas after 0.5h of chlorine gas introduction, and take it out after cooling to room temperature to obtain chloroplatinic acid sodium powder;

[0041] (2) Hydrolysis to generate sodium hexahydroxyplatinate: Dissolve 1000g of analytically pure sodium hydroxide in 19000mL of ultrapure water to prepare a sodium hydroxide solution with a mass f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com