Medically degradable Zn-based composite and preparing method and application thereof

A composite material, zinc-based technology, used in medical science, prosthesis, surgery, etc., can solve the problem that the content of other elements cannot be too high, and cannot meet the requirements of rapid degradation of zinc alloys, and achieves adjustable degradation speed and easy to fall off. , the effect of fast degradation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

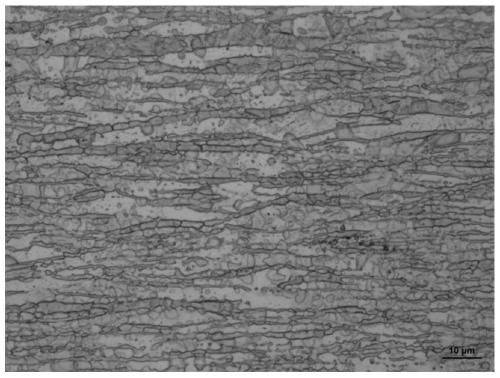

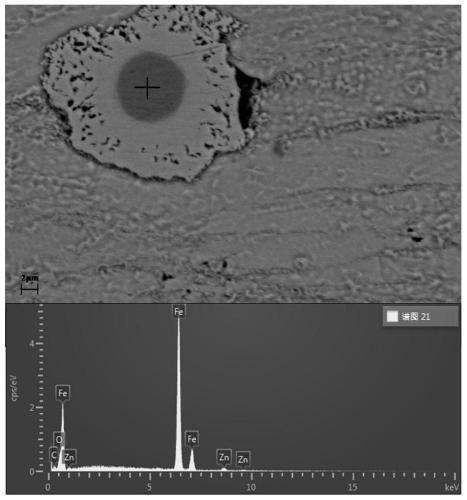

Embodiment 1

[0037] The element composition and mass percentage of the zinc-based composite material provided in this embodiment are: Zn: 99.5%, Fe: 0.5%.

[0038] The preparation method of the above-mentioned zinc-based composite material comprises the following steps:

[0039] (1) The particle size of the zinc powder is 25 μm, the particle size of the Fe powder is 50 μm, and the purity of all powders is 99.9%;

[0040] (2) Weigh various powders according to different usage requirements according to the mass ratio, and mix them evenly at room temperature;

[0041] (3) The mixed powder is placed in a mould, and it is pressed and formed at room temperature, and the pressing pressure is 50Mpa;

[0042] (4) Place the pressed composite material blank in a mold of the same size and specification, pressurize and sinter under nitrogen protection atmosphere, first raise the temperature to 200°C, keep it for 30 minutes, then continue to raise the temperature to 400°C, keep it for 5 minutes, the wh...

Embodiment 2

[0047] The element composition and mass percentage of the zinc-based composite material provided in this embodiment are: Zn 99.5%, Ag 0.5%.

[0048] The preparation method of the above-mentioned zinc-based composite material comprises the following steps:

[0049] (1) The particle size of zinc powder is 50 μm, the particle size of Ag powder is 50 μm, and the purity of all powders is above 99.9%;

[0050] (2) Weigh various powders according to different usage requirements according to the mass ratio, and mix them evenly at room temperature;

[0051] (3) The mixed powder is placed in a mould, and it is pressed and formed at room temperature, and the pressing pressure is 20Mpa;

[0052] (4) Place the pressed composite blank in a mold of the same size and specification, pressurize and sinter under nitrogen protection atmosphere, first raise the temperature to 250°C, keep it for 20 minutes, then continue to raise the temperature to 400°C, and keep it for 30 minutes. Keep the pressu...

Embodiment 3

[0056] The element composition and mass percentage of the zinc-based composite material provided in this embodiment are: Zn 99.5%, Ti 0.5%.

[0057] The preparation method of the above-mentioned zinc-based composite material comprises the following steps:

[0058] (1) The particle size of the zinc powder is 100 μm, the particle size of the Ti powder is 150 μm, and the purity of all powders is above 99.9%;

[0059] (2) Weigh various powders according to different usage requirements according to the mass ratio, and mix them evenly at room temperature;

[0060] (3) The mixed powder is placed in a mould, and it is pressed and formed at room temperature, and the pressing pressure is 50Mpa;

[0061] (4) Place the pressed composite material blank in a mold of the same size and specification, pressurize and sinter under nitrogen protection atmosphere, first raise the temperature to 250°C, keep it for 30 minutes, then continue to raise the temperature to 450°C, keep it for 30 minutes,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com