Lithium battery anode material and preparation method thereof, and lithium battery

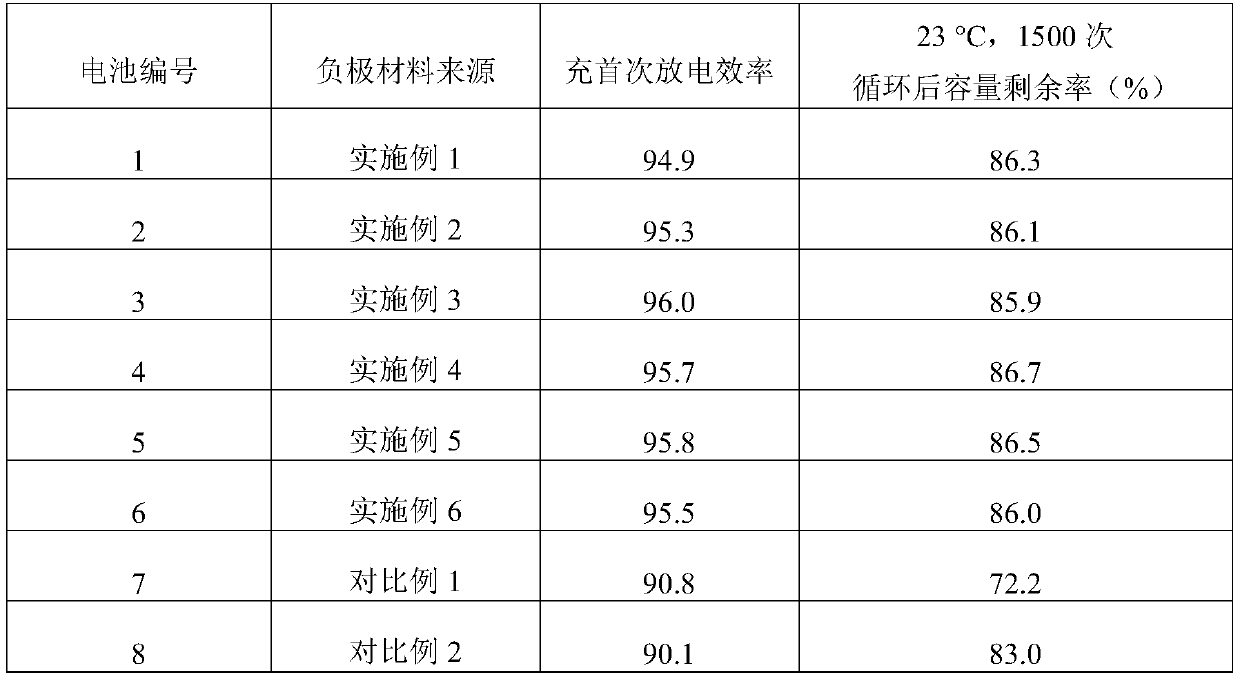

A negative electrode material, lithium battery technology, applied in the direction of battery electrodes, electrode carriers/collectors, secondary batteries, etc., can solve the problem of reducing the charge and discharge efficiency of electrode materials, SEI on the surface of electrode materials needs to be further deepened, and the irreversible capacity of the first charge and discharge increases and other problems, to achieve the effect of improving the first charge and discharge efficiency, reducing the first capacity loss, and reducing the amount of electrolyte injection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

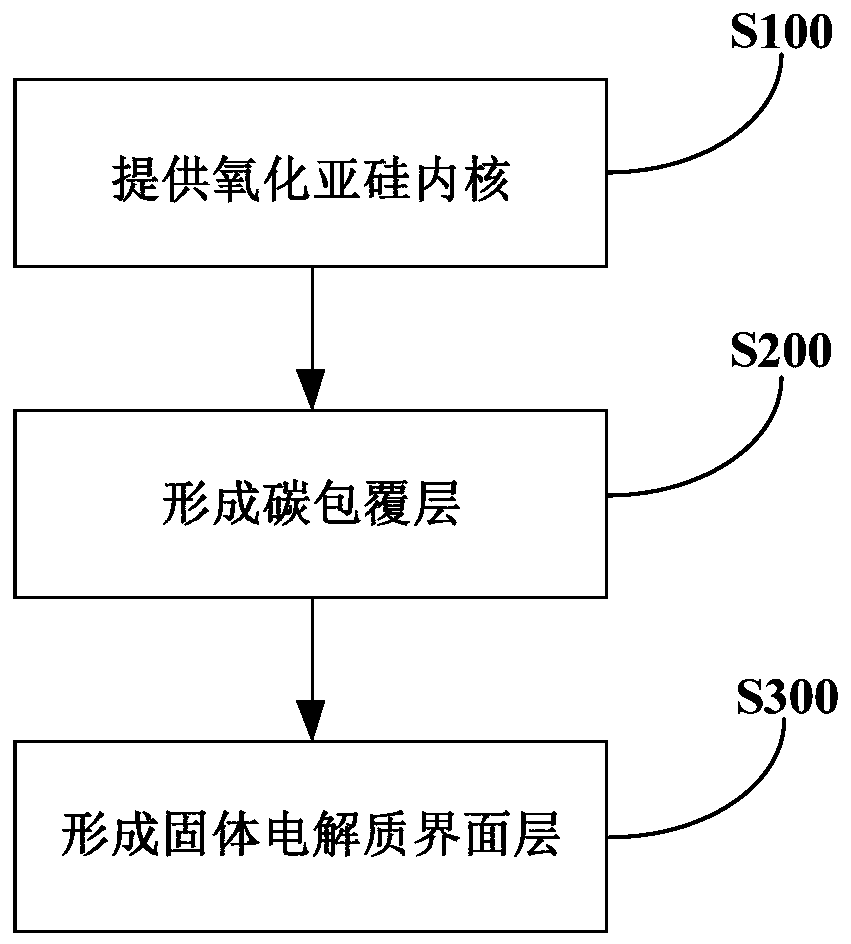

[0073] Prepare lithium battery negative electrode material according to general method, wherein,

[0074] In step (1), the average particle diameter of the silicon oxide inner core is 1 μm;

[0075] In step (2), using pitch as a carbon source, a carbon coating layer with a thickness of 2 μm is formed on the surface of the silicon oxide core by a liquid phase coating method;

[0076] In step (3), the electrolyte solution components include: ethylene carbonate: dimethyl carbonate: ethyl methyl carbonate = 1:1:1 (volume ratio), vinylene carbonate 0.1v%, the artificial SEI thickness that forms is 2nm.

Embodiment 2

[0078] Prepare lithium battery negative electrode material according to general method, wherein,

[0079] In step (1), the average particle diameter of the silicon oxide inner core is 3 μm;

[0080] In step (2), using ethane as a carbon source, a carbon coating layer with a thickness of 10 μm is formed on the surface of the silicon oxide core;

[0081] In step (3), the electrolyte solution components include: ethylene carbonate: dimethyl carbonate: ethyl methyl carbonate = 1:1.5:1 (volume ratio), vinylene carbonate 0.5v%, the artificial SEI thickness that forms is 1.5nm.

Embodiment 3

[0083] Prepare lithium battery negative electrode material according to general method, wherein,

[0084] In step (1), the average particle diameter of the silicon oxide inner core is 5 μm;

[0085] In step (2), using propane as a carbon source, a carbon coating layer with a thickness of 30 μm is formed on the surface of the silicon oxide core;

[0086] In step (3), the electrolyte solution components include: ethylene carbonate: dimethyl carbonate: ethyl methyl carbonate=1.5:1.5:1 (volume ratio), vinylene carbonate 1v%, fluoroethylene carbonate 5v% , lithium bis(fluorosulfonyl)imide 2.5v%, lithium bisfluorophosphate content 1.5v%, vinylene sulfate 5v%, propylene sulfite 5v%, tris(trimethylsilane) borate 5v% , the thickness of the formed artificial SEI is 10nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com