Pre-lithiated silicon-based negative electrode material as well as preparation method and application thereof

A pre-lithiated silicon-based, negative electrode material technology, applied in the direction of negative electrode, silicon oxide, battery electrode, etc., can solve the problems of unfavorable large-scale production, extremely high operating environment requirements, high lithium powder activity, and shorten the lithium intercalation. path, improve structural stability, improve cycle life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

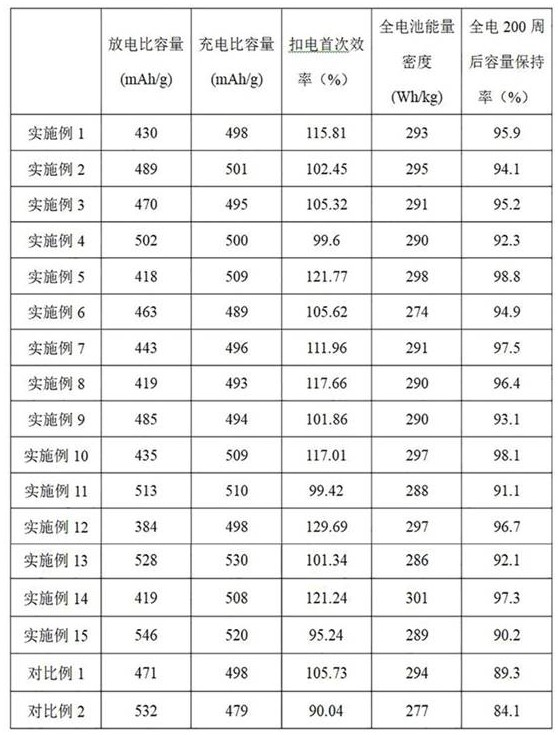

Examples

Embodiment 1

[0052] This embodiment provides a silicon-oxygen negative electrode material (commercial silicon oxide material SiO x ), the silicon-oxygen negative electrode material includes a silicon-oxygen material intercalating lithium inside and a fluorine-containing SEI film on the surface of the silicon-oxygen material.

[0053] The preparation method of the negative electrode material is as follows:

[0054] In the glove box, lithium flakes were added to a 0.5 mol / L solution of 4,4'-dimethylbiphenyl (4,4'-DMBP) in methyl butyl ether, where Li was mixed with 4, The molar ratio of 4'-DMBP is set to 4:1, and the Li-4,4'-DMBP complex is obtained by fully stirring, which is used as a chemical pre-lithiation solution; lithium hexafluorophosphate is added to the above solution to form a fluorine-containing chemical pre-lithium Lithium hexafluorophosphate accounts for 3% of the mass ratio of the solution to obtain a fluorine-containing Li-arene compound solution;

[0055] Put silicon-oxyge...

Embodiment 2

[0057] The difference between this example and Example 1 is that the aromatic hydrocarbon in this example is 4-methylbiphenyl (4-MBP).

[0058] All the other preparation methods and parameters are consistent with Example 1.

Embodiment 3

[0060] The difference between this example and Example 1 is that the aromatic hydrocarbon in this example is 3,3',4,4'-tetramethylbiphenyl (3,3',4,4'-TMBP).

[0061] All the other preparation methods and parameters are consistent with Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Areal density | aaaaa | aaaaa |

| Energy density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com