Silicon monoxide composite negative electrode material and preparation method thereof

A technology of silicon oxide and negative electrode materials, applied in the direction of negative electrodes, battery electrodes, active material electrodes, etc., can solve the problems of poor charge and discharge cycle performance, low Coulombic efficiency, and low conductivity of negative electrode materials, and achieve improved electrochemical performance , Improve the effect of low conductivity and improve conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

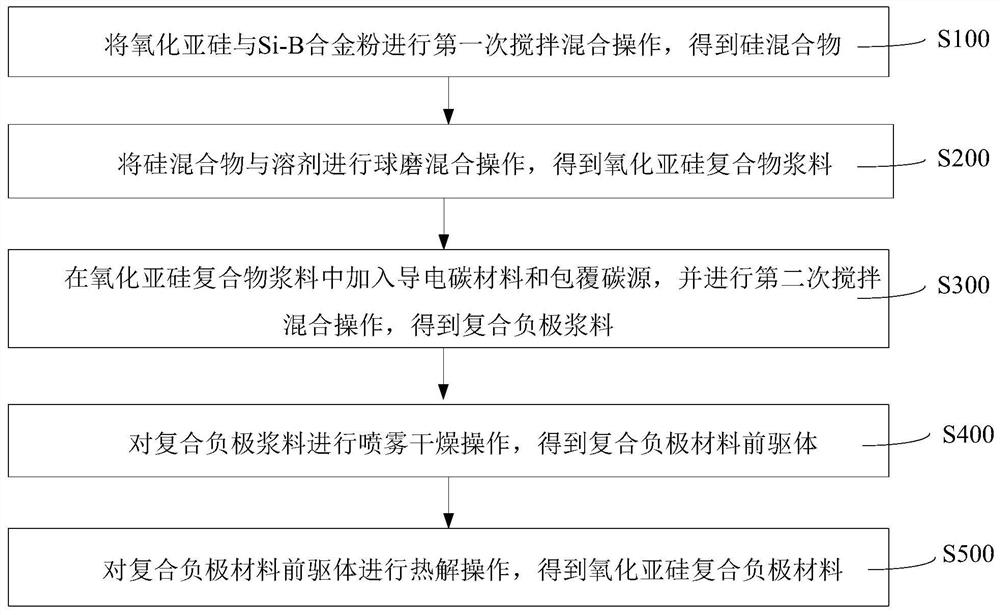

[0046] The present application also provides a method for preparing a silicon oxide composite negative electrode material as described in any one of the above embodiments, comprising the following steps: performing the first stirring and mixing operation of silicon oxide and Si-B alloy powder to obtain a silicon mixture; The silicon mixture is mixed with a solvent by ball milling to obtain a silicon oxide composite slurry; a conductive carbon material and a coated carbon source are added to the silicon oxide composite slurry, and a second stirring and mixing operation is performed to obtain a composite negative electrode slurry; performing a spray drying operation on the composite negative electrode slurry to obtain a composite negative electrode material precursor; performing a pyrolysis operation on the composite negative electrode material precursor to obtain the silicon oxide composite negative electrode material.

[0047] In the preparation method of the above silicon oxid...

Embodiment 1

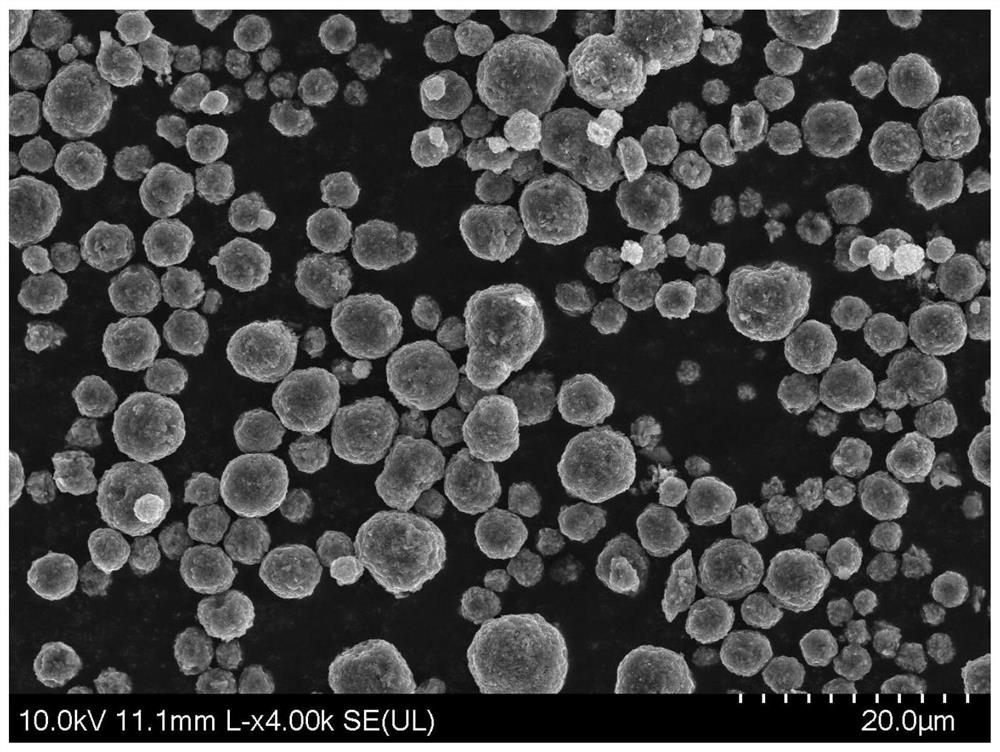

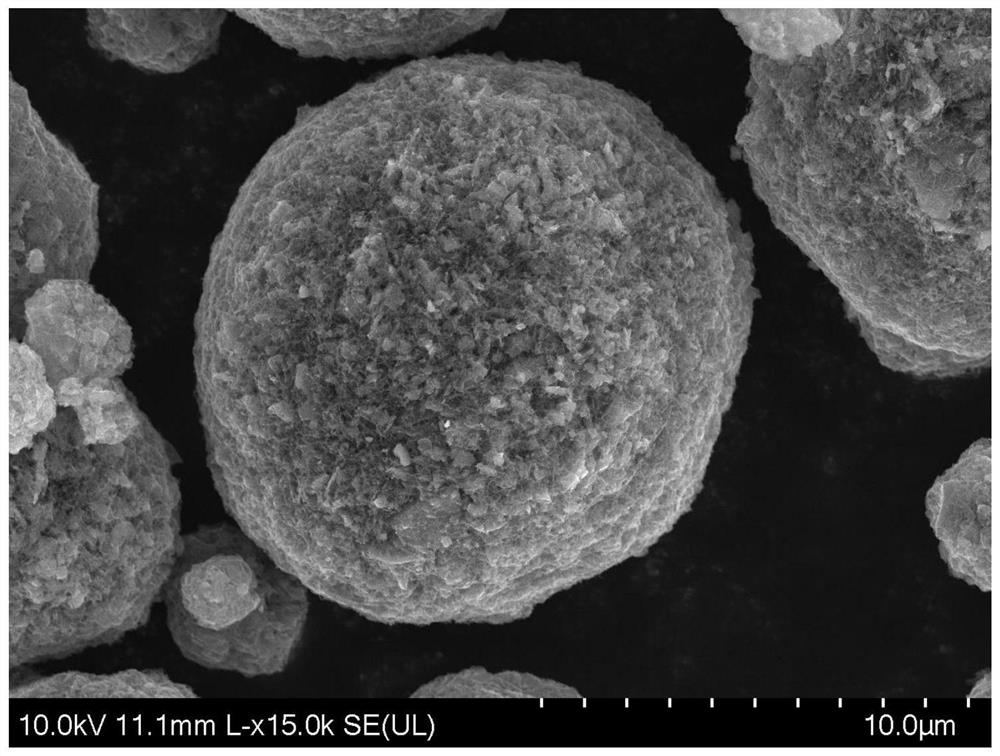

[0073] Add 5% Si-B alloy powder to silicon oxide, wherein the B content in Si-B alloy is 0.3%, and mix evenly; add the mixture to ethanol solution, wherein the weight ratio of the mixture to ethanol is 1:5 , added to a sand mill, and ball milled by a sand mill to obtain a silicon oxide mixed slurry; add 1.5% carbon nanotubes and 10% PVA to the mixed slurry, and stir evenly; spray-dry the mixed slurry to obtain a composite negative electrode material For the precursor, the inlet temperature of the spray drying is 180°C, and the outlet temperature is 80°C; the precursor is placed in a pyrolysis furnace at a temperature of 800°C under an argon protective atmosphere for 2 hours, and cooled to room temperature to obtain silicon oxide Composite anode materials.

Embodiment 2

[0075]Add 10% Si-B alloy powder to silicon oxide, wherein the B content in Si-B alloy is 0.5%, and mix evenly; add the mixture to ethanol solution, wherein the weight ratio of the mixture to ethanol is 1:4 , added to a sand mill, and ball milled by a sand mill to obtain a silicon oxide mixed slurry; add 2% carbon nanotubes and 10% SBR to the mixed slurry, and stir evenly; spray-dry the mixed slurry to obtain a composite negative electrode material For the precursor, the inlet temperature of spray drying is 200°C, and the outlet temperature is 90°C; the precursor is placed in a pyrolysis furnace at a temperature of 850°C under an argon protective atmosphere for 2 hours, and cooled to room temperature to obtain silicon oxide Composite anode materials.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com