Pre-lithiated silicon-based negative electrode plate as well as preparation method and application thereof

A technology of pre-lithiated silicon base and negative pole piece, applied in the direction of negative electrode, battery electrode, active material electrode, etc., can solve the problem of unstable SEI formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

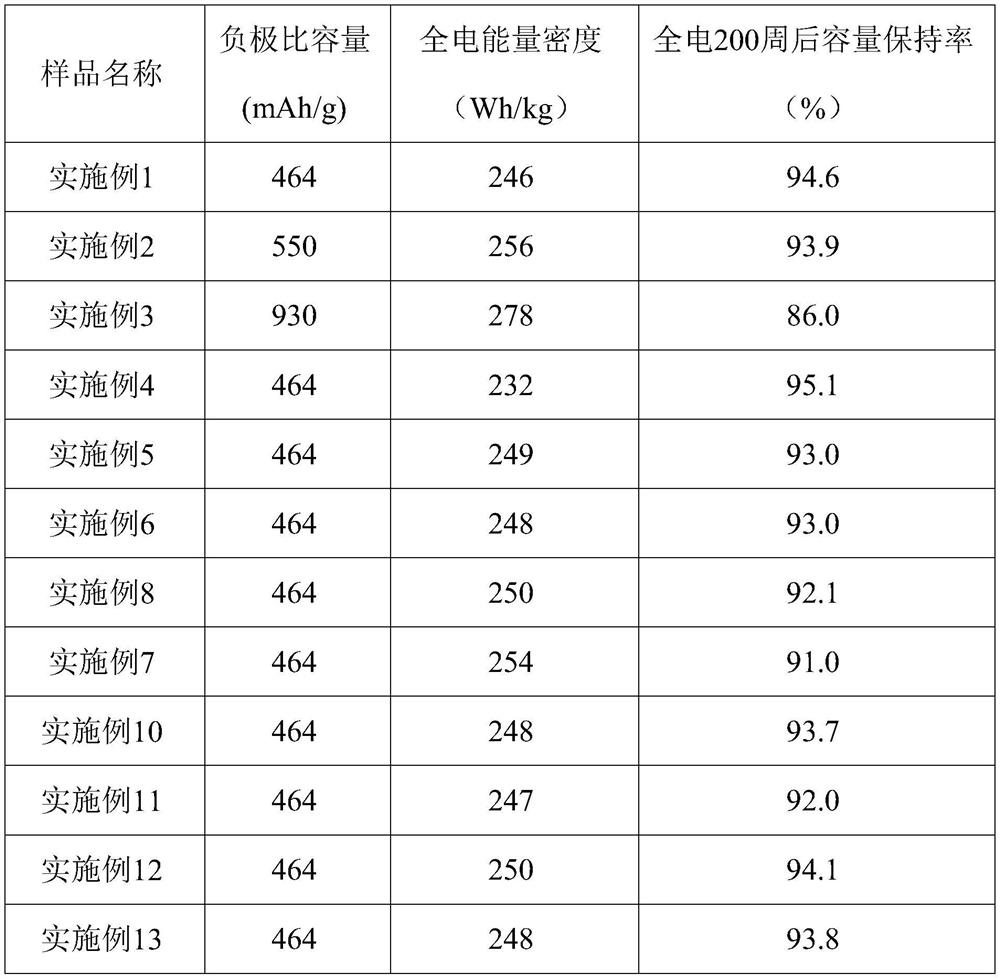

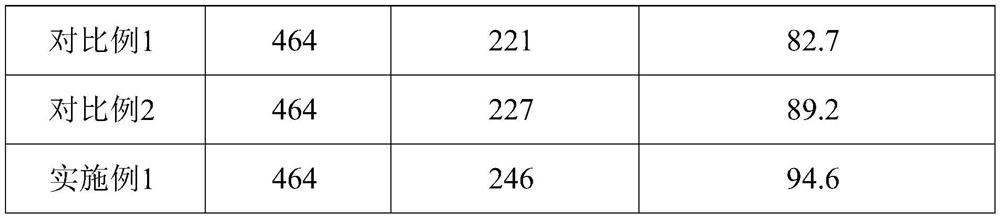

Examples

Embodiment 1

[0058] This embodiment provides a pre-lithiated silicon-based negative electrode sheet, and the preparation method of the pre-lithiated silicon-based negative electrode sheet is as follows:

[0059] (1) Mix silicon oxide and graphite at a ratio of 1:10 to make a negative electrode material with a specific capacity of 464mAh / g, and mix the negative electrode active material, conductive agent SP, and binder at a mass ratio of 80:12:8 , add an appropriate amount of deionized water, apply the mixed slurry on the upper surface of the copper foil and dry it. The electrode surface density is 20mg / cm 2 , the compacted density is 1.6g / cm 3; Micropores are formed on the surface of the silicon-oxygen inorganic sheet by laser etching, the opening size of the micropores is 20 μm, the depth is 100 μm, and the spacing between the micropores is 200 μm;

[0060] (2) In the glove box, make a Li-4,4'-DMBP complex with a concentration of 1.0mol / L as a chemical pre-lithiation reagent;

[0061] ...

Embodiment 2

[0063] This embodiment provides a pre-lithiated silicon-based negative electrode sheet, and the preparation method of the pre-lithiated silicon-based negative electrode sheet is as follows:

[0064] (1) Mix silicon oxide and graphite at a ratio of 1:10 to make a negative electrode material with a specific capacity of 464mAh / g, and mix the negative electrode active material, conductive agent SP, and binder at a mass ratio of 80:12:8 , add an appropriate amount of deionized water, apply the mixed slurry on the upper surface of the copper foil and dry it. The surface density of pole piece is 8mg / cm 2 , the compacted density is 1.6g / cm 3 ; Micropores are formed on the surface of the silicon-oxygen inorganic sheet by laser etching, the opening diameter of the micropores is 25 μm, the depth is 120 μm, and the spacing between the micropores is 300 μm;

[0065] (2) In the glove box, make a Li-4,4'-DMBP complex with a concentration of 1.0mol / L as a pre-lithiation reagent;

[0066] (...

Embodiment 3

[0068] The only difference between this embodiment and embodiment 1 is that the areal density of the pole piece described in step (1) is 25 mg / cm 2 , other conditions and parameters are exactly the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com