A preparation method of low molecular weight hyaluronic acid based on near-infrared spectroscopy

A technology of near-infrared spectroscopy and hyaluronic acid, which is applied in the field of preparation of low-molecular-weight hyaluronic acid, can solve the problems of not being widely applicable, inaccurate analysis of trace substances, inaccurate primary data, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] The preparation of embodiment 1 chondroitin sulfate enzyme ABC I

[0063] Chondroitin Sulfate ABC lyase I (Chondroitin Sulfate ABC lyase I, ChS ABC lyase I) is an enzyme that can degrade glycosaminoglycans expressed in Proteus vulgaris (ordered from ATCC), and has been studied (J BIOL CHEM,1997,272(14):9123-9130; J.Mol.Biol.(2003)328,623-634) confirmed that the enzyme is an endonuclease, which can degrade chondroitin sulfate A-C and HA by β-elimination 1,4-hexosamine linkage, giving low M r of chondroitin sulfate and HA. At present, there have been reports on the recombinant expression of chondroitinase ABC I, all of which use Escherichia coli as the carrier bacteria, and use different fusion vectors to add different tags to facilitate extraction. After extraction, higher enzyme activity can be achieved, proving that Recombinant expression of chondroitinase ABC I is feasible, for example, according to Biochem.J. (2005) 386, 103-112 (Printed in Great Britain); Appl M...

Embodiment 2

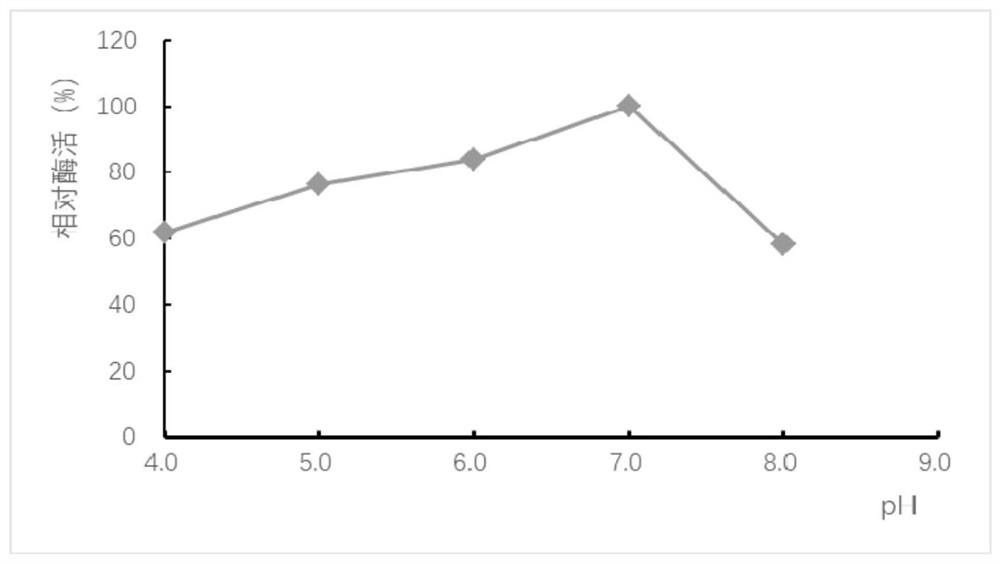

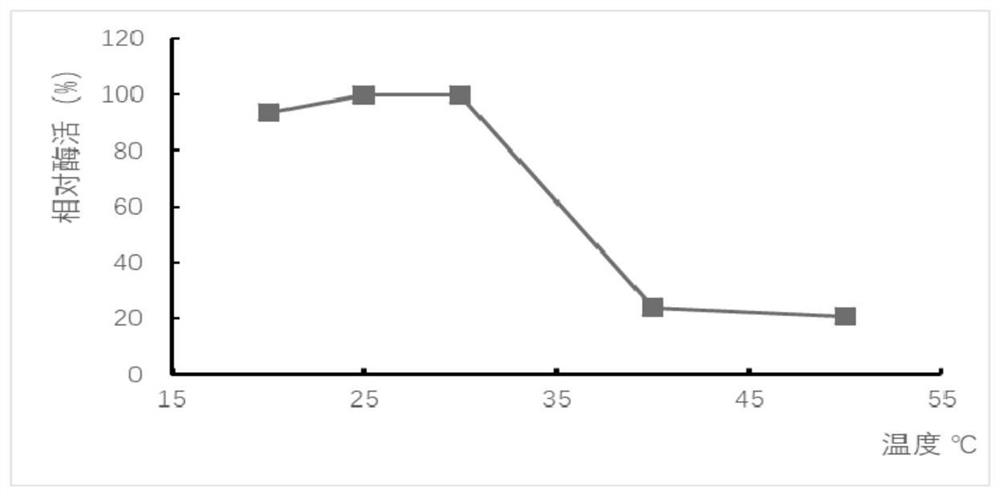

[0099] Example 2 Enzymatic Properties of Chondroitinase ABC I

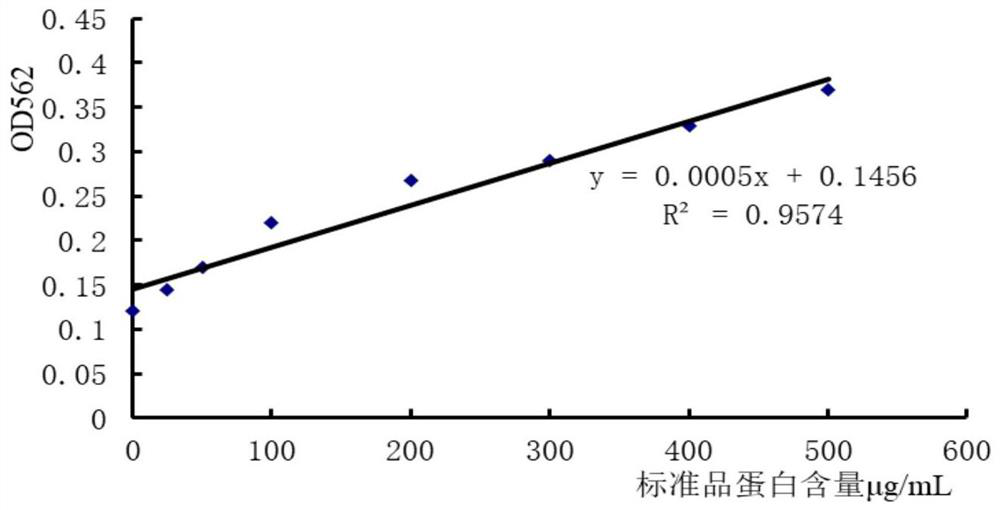

[0100] 1. The enzyme activity assay method of chondroitin sulfate enzyme ABC I

[0101] Enzyme activity unit definition: In this example, the enzyme activity unit U is defined as an enzyme that catalyzes the reaction of 0.2% HA solution at 25°C and pH 7.0, and causes an increase in absorbance of 0.001 per minute at a wavelength of 232nm quantity.

[0102] Determination of enzyme activity: Take a certain amount of 0.2% HA solution, put it in a 2mL Ep tube, add a certain volume of chondroitin sulfate ABC I enzyme solution, and react at 25°C, immediately heat and boil for 5min to terminate the reaction. The light absorption value (A232) was detected at 232 nm with a UV spectrophotometer.

[0103] The calculation formula of enzyme activity is as follows:

[0104]

[0105] Where: ΔA 232 Refers to the change in absorbance before and after the reaction; t refers to the reaction time (min); Vt refers to the total...

Embodiment 3

[0136] Example 3 Preparation of LMW-HA

[0137] 1. Example supplies

[0138] Reagents and materials

[0139] Hyaluronic acid (HA), Shandong Freda Pharmaceutical Group Co., Ltd.; ethanol (analytical pure), Tianjin Fuyu Fine Chemical Co., Ltd.; ammonium bicarbonate (analytical pure), ammonium acetate (analytical pure), trimethylol Aminomethane (Tris), sodium chloride (analytical pure), silver nitrate (chemical pure), glacial acetic acid (analytical pure), nitric acid (analytical pure), hydrochloric acid (analytical pure), Sinopharm Chemical Reagent Co., Ltd.; chondroitin sulfate Enzyme ABC I (prepared in Example 1), double distilled water, triple distilled water, self-made.

[0140] Commonly used solution preparation method

[0141] (1) 50mol / L Tris-HCl solution: Weigh 3.028g of Tris, add 500mL of double distilled water, and adjust the pH to 7.0 with hydrochloric acid.

[0142] (2) 5 mol / L ammonium acetate solution: weigh 0.19 g of ammonium acetate, add 500 mL of double d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com