A method for inhibiting microbial corrosion of metal material pipelines

A technology for microbial corrosion and metal materials, applied in the field of inhibiting microbial corrosion of metal material pipelines, can solve the problems of poor hydrophobicity, short anti-corrosion life and general dispersibility of film-forming substances, reduce deposition corrosion rate, improve impact resistance, The effect of avoiding galvanic corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

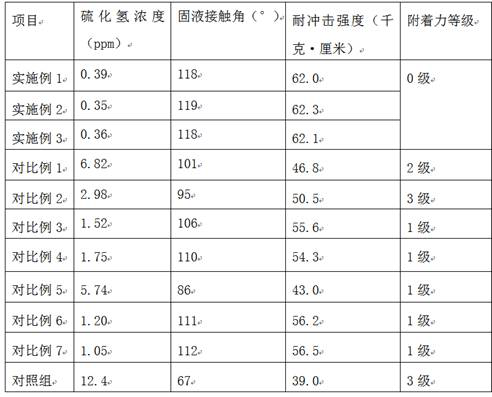

Examples

Embodiment 1

[0022] A method for inhibiting microbial corrosion of metal material pipelines. The prepared antibacterial and anticorrosive materials are added to epoxy resin to prepare anticorrosive coatings, and coated on the surface of metal material pipelines. The preparation method of the antibacterial and anticorrosive materials includes the following steps:

[0023] (1) Weigh 14 grams of silicon nitride fine powder and add it to 50 ml of n-butanol aqueous solution, ultrasonically disperse for 20 minutes, then add 1.0 grams of silane coupling agent, stir mechanically for 30 minutes, add 4.6 grams of cerium oxide fine powder to In the above mixture, continue to stir for 60 minutes, transfer it to the reaction kettle, add 4 ml of polymethyl methacrylate-carbon tetrachloride mixture to seal, pressurize and heat up the reaction, the reaction temperature is 260 ° C, and the reaction time is 17 hours After the reaction was completed, it was naturally cooled to room temperature, and the produc...

Embodiment 2

[0037] A method for inhibiting microbial corrosion of metal material pipelines. The prepared antibacterial and anticorrosive materials are added to epoxy resin to prepare anticorrosive coatings, and coated on the surface of metal material pipelines. The preparation method of the antibacterial and anticorrosive materials includes the following steps:

[0038] (1) Weigh 14.5 grams of silicon nitride fine powder and add it to 55 ml of n-butanol aqueous solution, ultrasonically disperse for 22 minutes, then add 1.1 grams of silane coupling agent, stir mechanically for 35 minutes, add 4.7 grams of cerium oxide fine powder to In the above mixture, continue to stir for 65 minutes, transfer to the reaction kettle, add 4.5 ml of polymethyl methacrylate-carbon tetrachloride mixture to seal, pressurize and heat up to react, the reaction temperature is 270 ° C, and the reaction time is 18 hours After the reaction was completed, it was naturally cooled to room temperature, and the product w...

Embodiment 3

[0052] A method for inhibiting microbial corrosion of metal material pipelines. The prepared antibacterial and anticorrosive materials are added to epoxy resin to prepare anticorrosive coatings, and coated on the surface of metal material pipelines. The preparation method of the antibacterial and anticorrosive materials includes the following steps:

[0053] (1) Weigh 15 grams of silicon nitride fine powder and add it to 60 ml of n-butanol aqueous solution, ultrasonically disperse for 25 minutes, then add 1.2 grams of silane coupling agent, stir mechanically for 40 minutes, add 4.8 grams of cerium oxide fine powder to In the above mixture, continue to stir for 70 minutes, transfer to the reaction kettle, add 5 ml of polymethyl methacrylate-carbon tetrachloride mixture to seal, pressurize and heat up for reaction, the reaction temperature is 280 ° C, and the reaction time is 20 hours After the reaction was completed, it was naturally cooled to room temperature, and the product w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com