One-bath one-step processing method for dyeing and waterproof finishing of polyester fabric

A processing method and waterproof finishing technology, which is applied in the field of dyeing and finishing of textile fabrics, can solve the problems of waterproof finishing and softener influence, rough and hard fabrics, insufficient washing, etc., to achieve good production efficiency and environmental friendliness, good Economic and social benefits, the effect of saving functional finishing additives

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

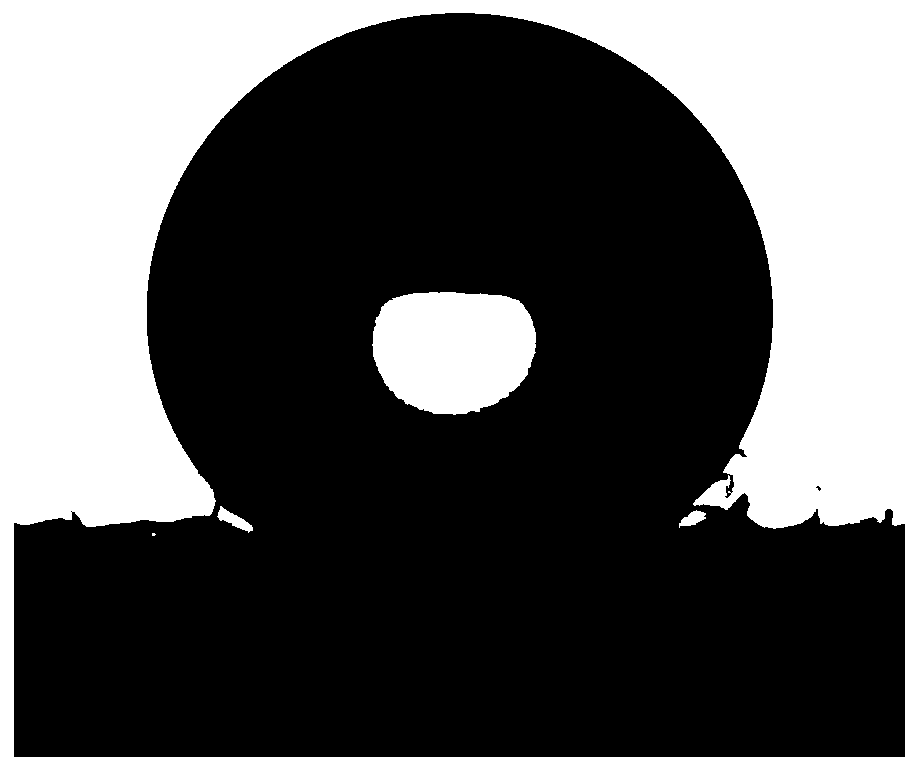

[0027] The dyeing and waterproofing process is carried out on a Rapid infrared dyeing machine (Ruibi, Taiwan). The fabric selection density is 300T, the yarn count is 50D, and the weight is 68g / m 2 Polyester pongee fabric 4g.

[0028] Dyeing at room temperature, immerse the polyester to be dyed in the working solution, the bath ratio is 1:40, the working solution is composed of the following components: Longsheng Company Disperse Blue 2BLN1% o.w.f, Rudolf environmental protection polyester non-ionic leveling agent Rucogal ERQ 1g / L, the concentration of non-ionic water repellent TG-5671 of Daikin Company is 0.5g / L, add acetic acid-sodium acetate buffer solution to adjust the pH to 5, raise the temperature to 90°C at a heating rate of 3°C / min, keep it warm for 10min, and then increase the temperature at 1 ℃ / min heating rate up to the working temperature of 130°C, and keep warm at 130°C for 45 minutes, so that the dyeing and waterproof finishing can be carried out at the same t...

Embodiment 2

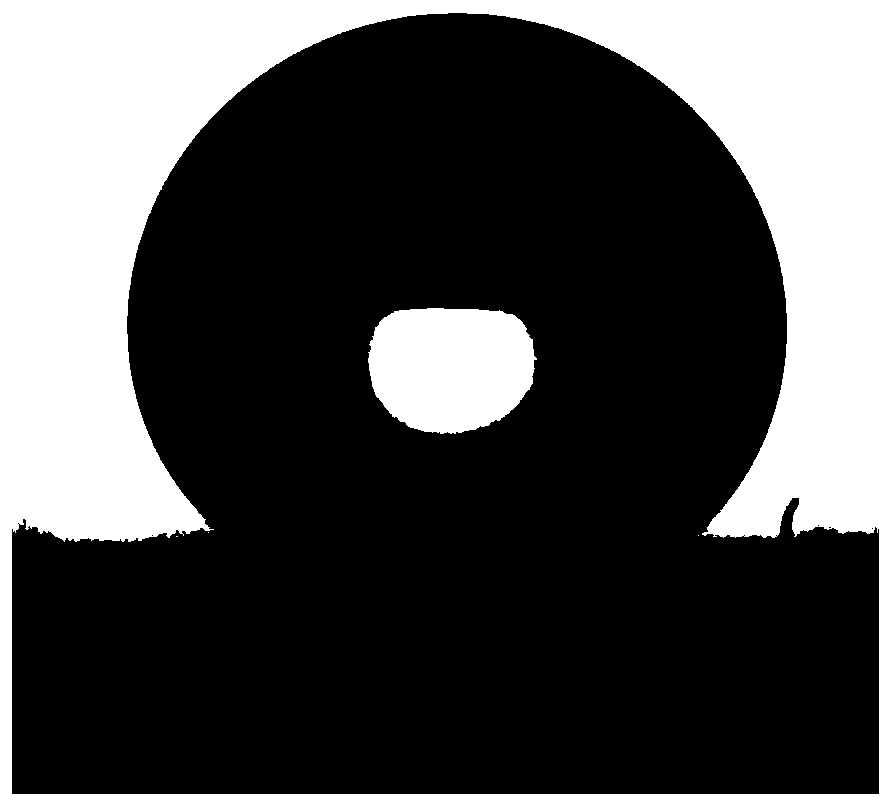

[0030] The dyeing and waterproofing process is carried out on a Rapid infrared dyeing machine (Ruibi, Taiwan). The fabric selection density is 300T, the yarn count is 50D, and the weight is 68g / m 2 Polyester pongee fabric 4g.

[0031]Dyeing at room temperature, immerse the polyester to be dyed in the working solution, the bath ratio is 1:40, the working solution is composed of the following components: Longsheng Company Disperse Blue 2BLN 1% o.w.f, Rudolph environmental protection polyester non-ionic leveling agent Rucogal ERQ 1g / L, Demei nonionic softener CGF-343 10g / L, Daikin nonionic water repellent TG-5671 concentration is 20g / L, add acetic acid-sodium acetate buffer solution to adjust pH to 5, and heat up at 3°C / min Raise the temperature to 90°C, keep it warm for 10 minutes, then raise it to the working temperature of 130°C at a heating rate of 1°C / min, and keep it at 130°C for 45 minutes, so that the dyeing and waterproof finishing can be carried out at the same time, ...

Embodiment 3

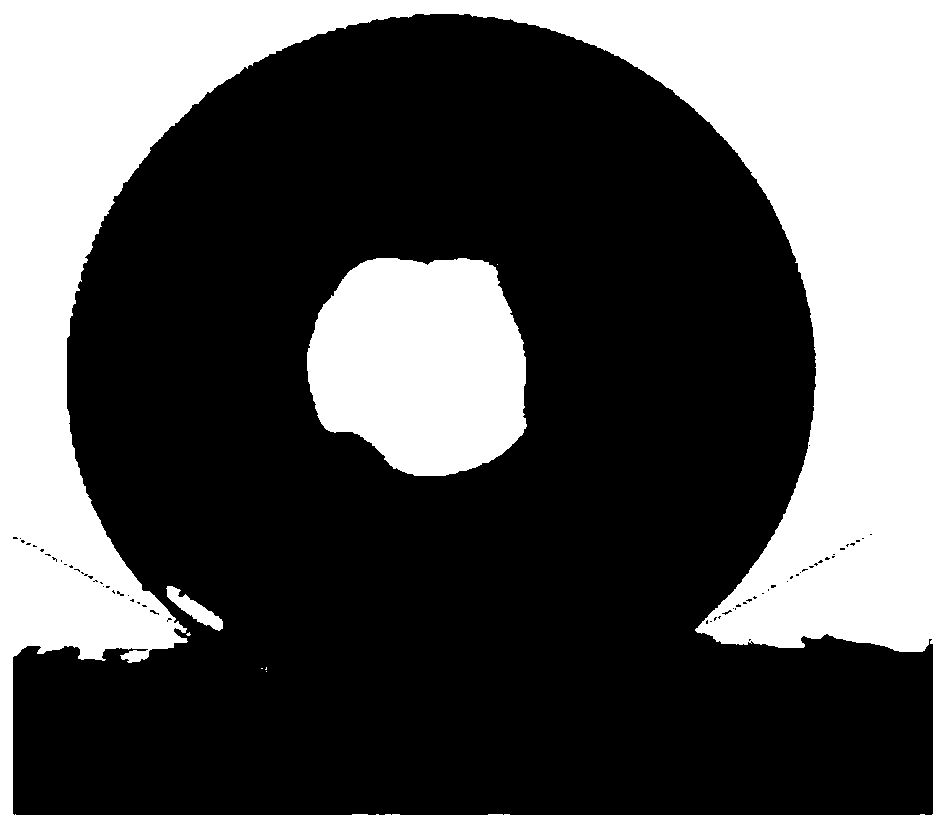

[0033] The dyeing and waterproofing process is carried out on a Rapid infrared dyeing machine (Ruibi, Taiwan). The fabric selection density is 190T, the yarn count is 63D, and the weight is 54g / m 2 polyester taffeta fabric 4g.

[0034] Dyeing at room temperature, immerse the polyester to be dyed in the working solution, the bath ratio is 1:30, the working solution is composed of the following components: Longsheng Disperse Yellow ACE 1% o.w.f, Tuona high-efficiency non-ionic dispersing and leveling agent LEVEGAL HTN03 2g / L, the concentration of Asahi Glass Waterproofing Agent AG-E081 is 10g / L, add acetic acid-sodium acetate buffer solution to adjust the pH to 4.5, raise the temperature to 90°C at a heating rate of 2°C / min, keep warm for 15min, and then increase the temperature at 1°C / min The heating rate is raised to the working temperature of 135°C, and the temperature is kept at 135°C for 40 minutes, so that the dyeing and waterproof finishing can be carried out at the same...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com