600MPa large deformation resisting rebar and production method thereof

A technology of anti-large deformation and production method, applied in the field of high-strength steel bar production, can solve the problems of limitation, unfavorable promotion and application, lack of market competitiveness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solutions of the present invention will be further described below in conjunction with the examples.

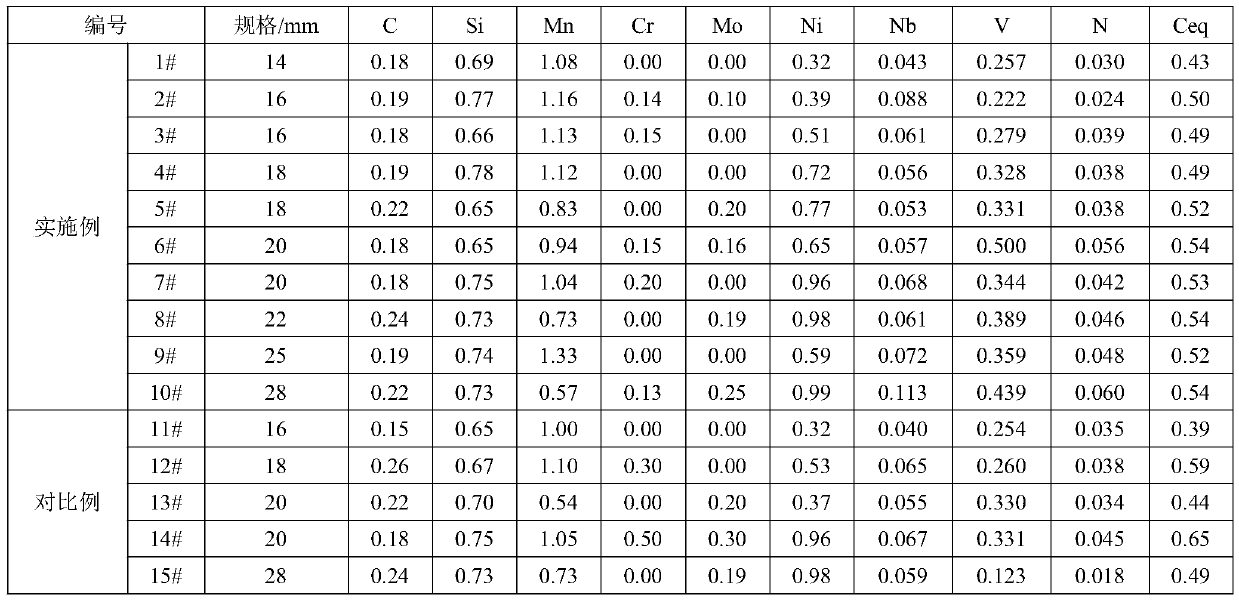

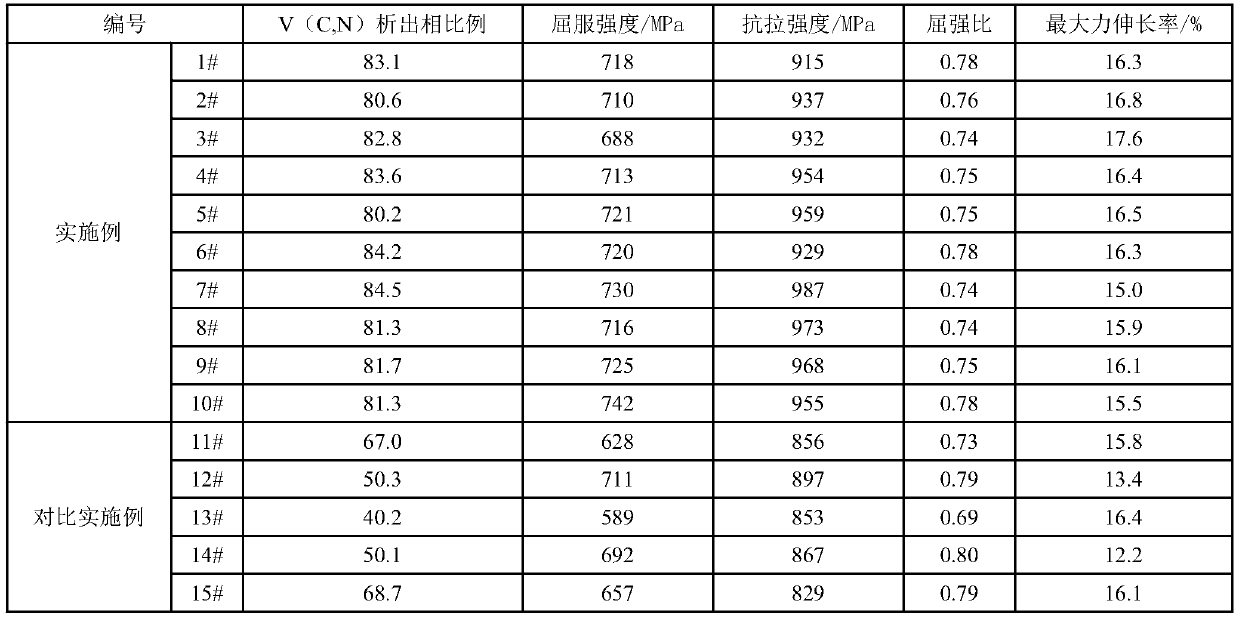

[0026] See Table 1 for the chemical components of Examples 1-10 and Comparative Examples 11-15.

[0027] Embodiments 1 to 10 adopt the short-flow production process of converter smelting+billet continuous casting+cooling bed cooling, and produce according to the following process flow:

[0028] (1) In the smelting and casting process, smelting is carried out according to the composition range and element ratio relationship of the steel bar, and VN alloy is added, and 0.3-0.5kg / t nitrogen increasing agent is added when the converter is tapping, and 0.4-0.6 is used after the converter is tapping. Molten steel is softly stirred by argon bottom blowing under MPa pressure for more than 5 minutes; cast into a billet with a cross-section of 140mm×140mm; the nitrogen-enhancing agent components used include: Si 3 N 4 35-65%, Ti 8-15%, Si 5-10%, Al 1-6%, Ca 1-5%,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com