Air-proof moisture-permeable freshness retaining composite film, manufacturing method and application

A composite film and fresh-keeping film technology, which is used in the production of fruit and vegetable fresh-keeping, the production of air-barrier, moisture-permeable and fresh-keeping composite film for fruits and vegetables in refrigerator freezers or fruit and vegetable boxes, and the field of special paper. Large, easy to produce condensation and other problems, to achieve excellent barrier oxygen and carbon dioxide gas passage ability, increase carbon dioxide concentration, good effect of humidity control and fresh-keeping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

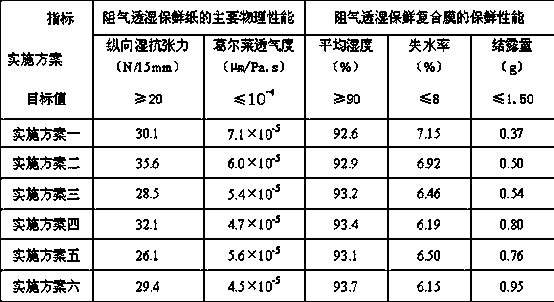

[0013] Embodiment one: base paper: 100% softwood pulp, softwood pulp beating degree 30 o SR, add 5% SWP fiber (relative to dry wood pulp), SWP fiber 3-4mm long, PAE 1.0%; papermaking equipment: fourdrinier paper machine. Subsequent processing of base paper: send the base paper into 20 o Partially hydrolyze in a sulfuric acid bath with a concentration of 72% of C for 100 seconds, then wash with water, put in 5% ammonia water to neutralize the residual acid, wash with water, and plasticize with 2% glycerin solution made by chemical treatment. The test results of the gas-barrier and moisture-permeable fresh-keeping paper and the gas-barrier and moisture-permeable fresh-keeping composite film are shown in Table 1.

Embodiment 2

[0014] Embodiment two: base paper: 100% softwood pulp, softwood pulp beating degree 50 o SR, add 5% SWP fiber (relative to dry wood pulp), SWP fiber 3-4mm long, PAE 1.0%; papermaking equipment: rotary paper machine. Subsequent processing of base paper: send the base paper into 25 o Partially hydrolyze in a sulfuric acid bath with 72% concentration of C for 80 seconds, then wash with water, put in 5% ammonia water to neutralize the residual acid, wash with water, and plasticize with 2% glycerin solution made by chemical treatment. The test results of the gas-barrier and moisture-permeable fresh-keeping paper and the gas-barrier and moisture-permeable fresh-keeping composite film are shown in Table 1.

Embodiment 3

[0015] Embodiment three: base paper: 80% softwood pulp: 20% hardwood pulp, softwood pulp beating degree 40 o SR, hardwood pulp 40 o SR, add 5% SWP fiber (relative to dry wood pulp), SWP fiber 3-4mm long, PAE 1.0%; papermaking equipment: fourdrinier paper machine. Subsequent processing of base paper: send the base paper into 25 o Partially hydrolyze in a sulfuric acid bath with 72% concentration of C for 80 seconds, then wash with water, put in 5% ammonia water to neutralize the residual acid, wash with water, and plasticize with 2% glycerin solution made by chemical treatment. The test results of the gas-barrier and moisture-permeable fresh-keeping paper and the gas-barrier and moisture-permeable fresh-keeping composite film are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com