A kind of preparation method of high oxygen storage cerium zirconium composite oxide

A composite oxide and oxygen storage technology, which is applied in chemical instruments and methods, catalyst activation/preparation, zirconia, etc., can solve the problems of low oxygen storage capacity and unsatisfactory practical application of cerium-zirconium composite oxides, and achieve remarkable results Oxygen storage capacity, save oxidation time, and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0051] The invention provides a preparation method of a cerium-zirconium composite oxide, comprising the steps of preparing by a hydrothermal method, and the details are as follows:

[0052] S1, dissolve the salts of cerium, zirconium and rare earth metals respectively, and the total concentration is 20-160g / L;

[0053] S2, adding 30% H to the above solution at a molar ratio of hydrogen peroxide to cerium oxide of 1.5-3:1 2 O 2 , stir and oxidize for 5-35min;

[0054] S3, drip alkaline precipitating agent, described alkaline precipitating agent is one or more in ammoniacal liquor, sodium hydroxide, amines, preferably is mainly based on ammoniacal liquor, then adjust solution pH to 1.5-2;

[0055] S4, introducing the above solution into a high-pressure reaction kettle, and performing a high-temperature hydrolysis reaction at 120-220° C. for 10-20h;

[0056] S5, adding an alkaline precipitant to the precursor slurry obtained in S3 dropwise to adjust the pH to 8-10;

[0057] ...

Embodiment 1

[0061] Embodiment 1 provides a kind of cerium-zirconium composite oxide, which is prepared by the following method:

[0062] Take 527.1g of zirconium nitrate, dissolve it in 2000ml of deionized water until it becomes clear, and take another 32.1g of yttrium oxide, dissolve it in 82.0g of concentrated nitric acid, and mix it with the above solution, then add 159.2g of ceric ammonium nitrate and 23.4g of lanthanum nitrate, and stir until it becomes clear , to obtain solution A, and then add 30% H into solution A at a ratio of 2:1 in which the molar ratio of hydrogen peroxide to cerium oxide in the obtained composite oxide is 2 O 2 , stirred and oxidized for 5min;

[0063] The oxidized solution A was adjusted to pH 1.5-2 with ammonia water under the condition of 50 ℃ water bath, the volume was adjusted to 6400ml, and introduced into the pressure-dissolving bomb lined with PTFE, and hydrothermally hydrolyzed at 180 ℃ for 20 hours, at room temperature Adjust the pH to about 9.5 w...

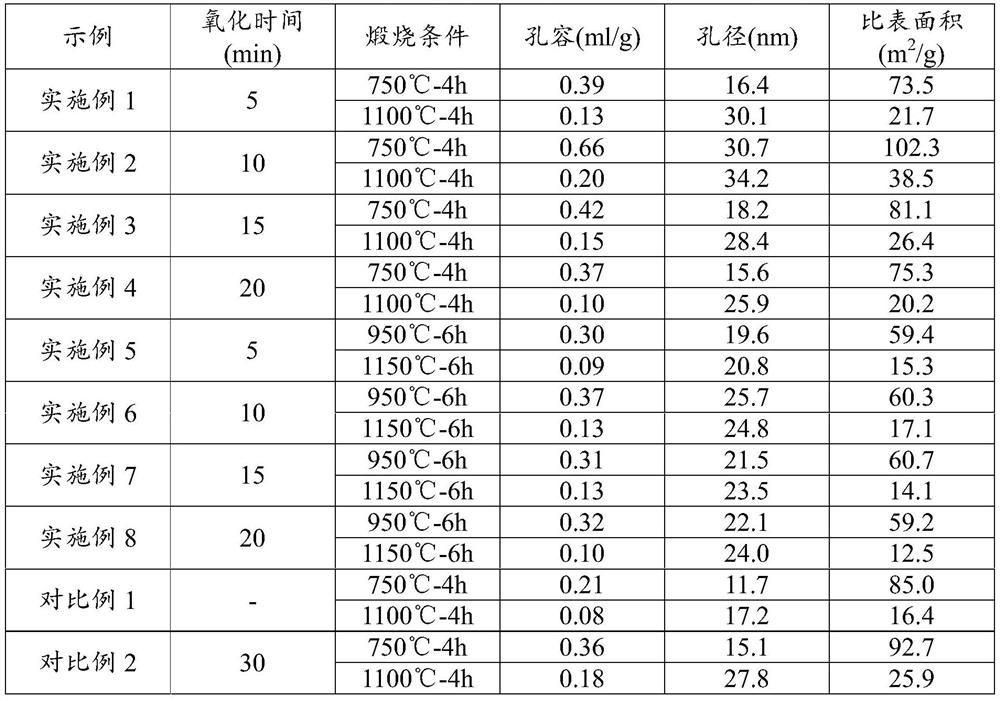

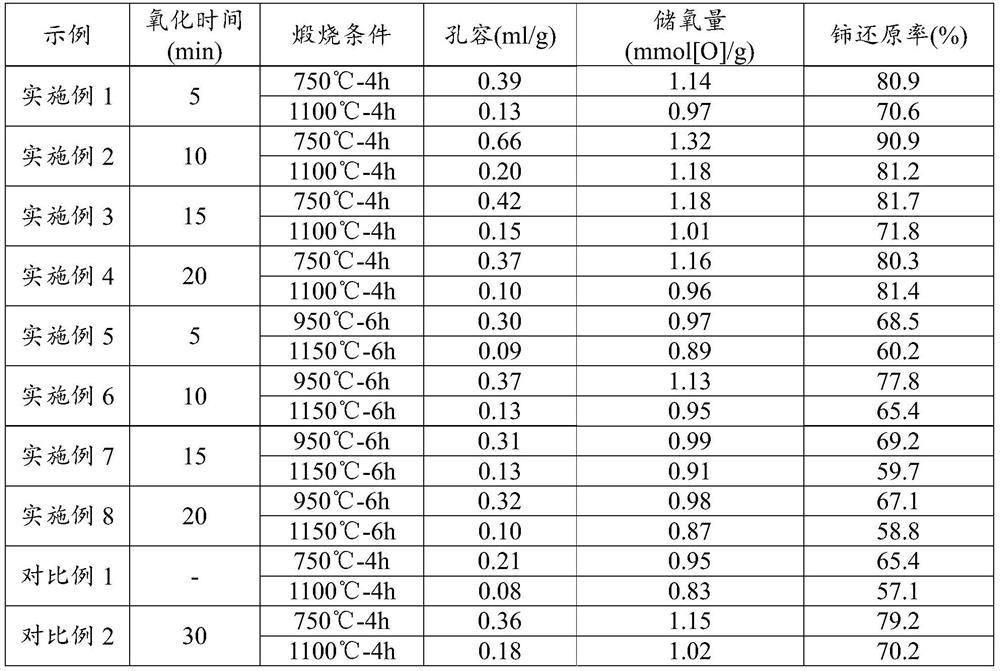

Embodiment 2-4

[0067] Examples 2-4 were prepared according to the preparation method of Example 1 to obtain a cerium-zirconium composite oxide (composition: CeO 2 20%, ZrO 2 65%, La 2 O 3 3.5%, Y 2 O 3 12.5%), the difference is only in the preparation process, adding 30% hydrogen peroxide to the mixed salt solution of cerium, zirconium and rare earth metals for stirring and oxidizing the time is different, the oxidation time of Examples 2-4 is 10min, 15min, 20min respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com