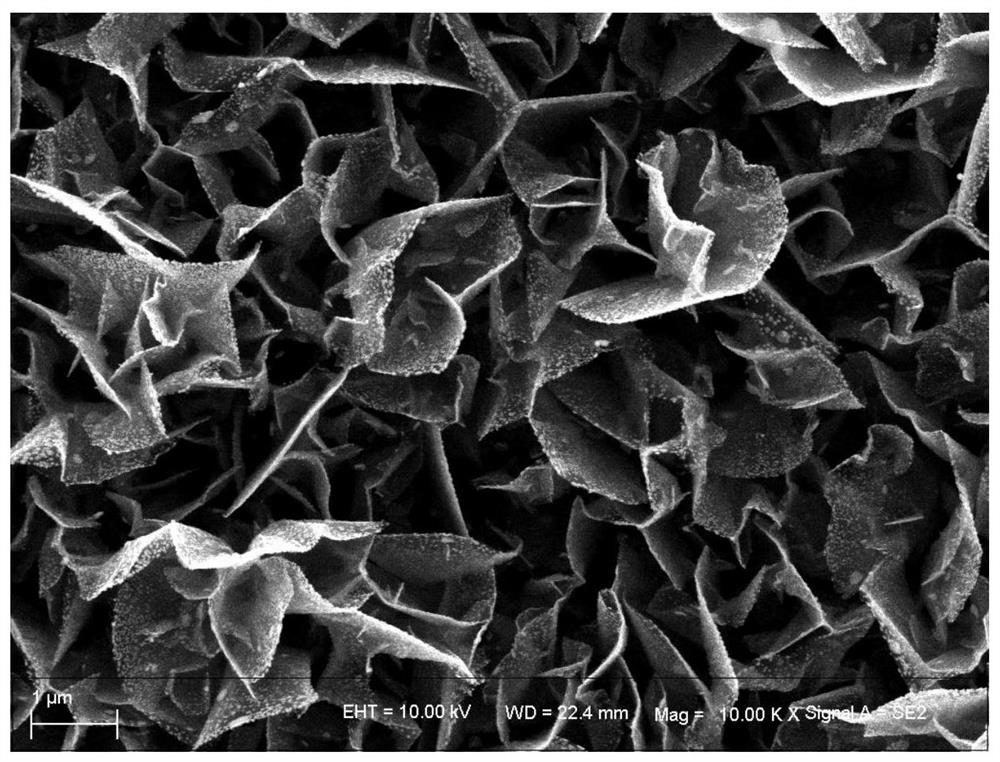

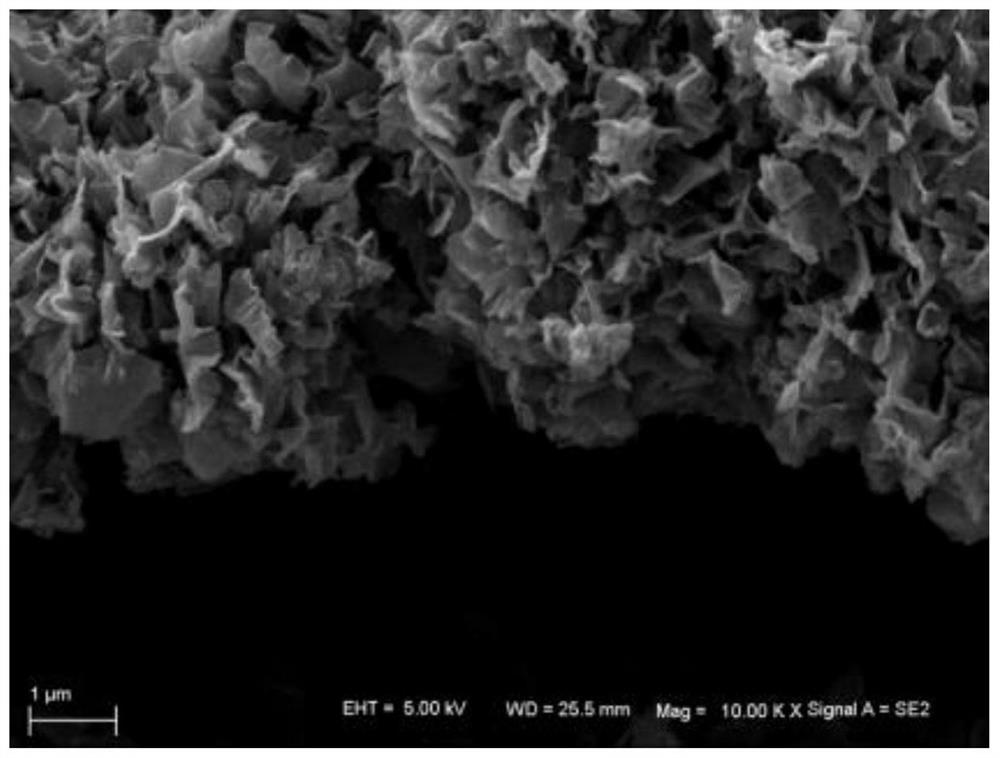

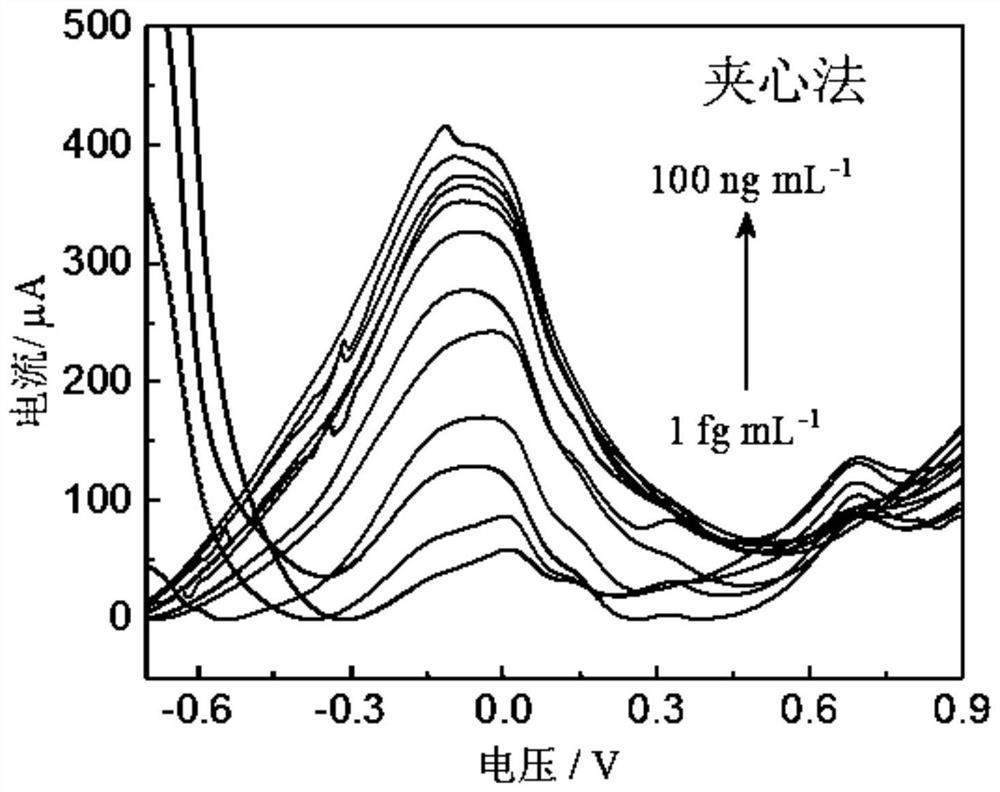

Gold-platinum co-modified graphene electrode and its preparation method and application

A graphene electrode and co-modification technology, which is applied to electrochemical variables of materials, material analysis by electromagnetic means, instruments, etc., can solve the problems of low accuracy, difficulty in automation, time-consuming and the like, and achieves a simple preparation method, Large specific surface area and high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0078] 15) Preparation method of glycine solution: add phosphoric acid dropwise into the phosphate buffer solution to make the pH of the phosphate buffer solution 2.4, and use the phosphate buffer solution to prepare a 0.1-0.2 mol / L glycine solution.

[0079] All reagents mentioned above were of analytical grade.

[0080] In the following examples, the involved instruments and models are as follows:

[0081] 1. Electrochemical workstation (CHI660E): Shanghai Chenhua Instrument Co., Ltd.

[0082] 2. Ultraviolet lamp (305nm): Shanghai Hualun Bulb Factory

[0083] 3. Magnetic stirrer (BII-2): Shanghai Sile Instrument Co., Ltd.

[0084] 4. SHZ-D(III) circulating water vacuum pump: Hebei Yuhua Instrument Co., Ltd. (for suction filtration)

[0085] 5. Constant temperature incubator (DH3600B II): Tianjin Test Instrument Co., Ltd.

[0086] 6. Nitrogen generator (SPN-500A): Beijing Zhonghui Analysis Technology Research Institute

[0087] 7. Youpu series ultrapure water device (UPH...

Embodiment 1

[0092] A preparation method of gold-platinum co-modified graphene electrode, comprising the following steps:

[0093] Step 1, prepare a glassy carbon sheet of 2cm×1cm and a thickness of 1mm, polish it clean, clean the glassy carbon sheet, and clean the glassy carbon sheet to remove organic and inorganic substances (dirt) on the surface of the glassy carbon sheet. The specific steps are: Purified water, absolute ethanol and ultrapure water were successively ultrasonically cleaned for 10 minutes, and dried at room temperature 25°C for 10 minutes.

[0094] Step 2, carry out direct current plasma chemical vapor deposition: put the glassy carbon sheet obtained in step 1 into the center of the sample stage in the sample chamber of direct current plasma chemical vapor deposition equipment, close the sample chamber (chamber) and evacuate to below 1Pa, and inject the The chamber is filled with argon and hydrogen at the same time. When filling, the flow rate of hydrogen is 2L / min, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com