Positive active material, preparation method thereof, positive electrode and battery

A positive active material and positive electrode technology, which is applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of poor battery conductivity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

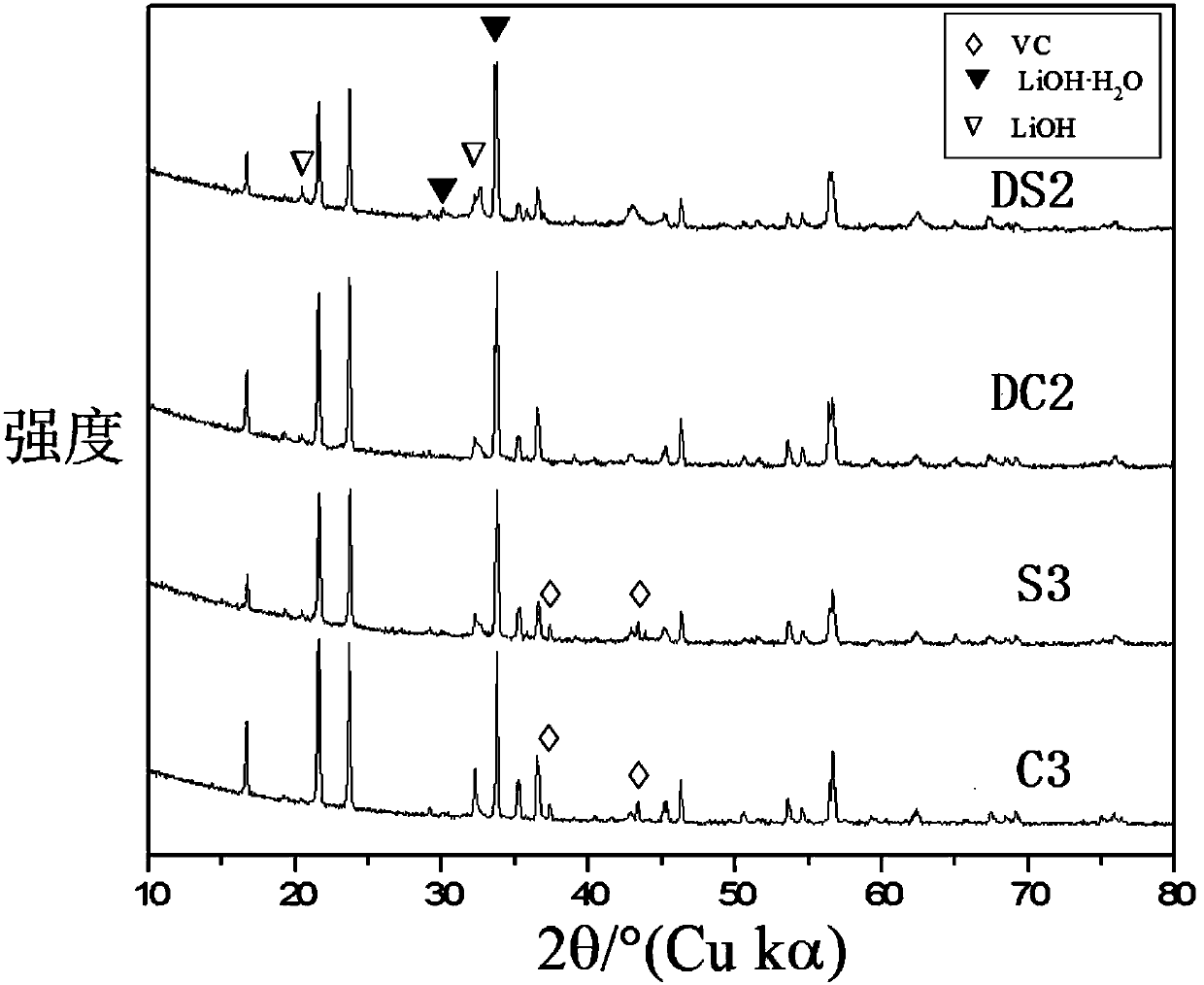

Image

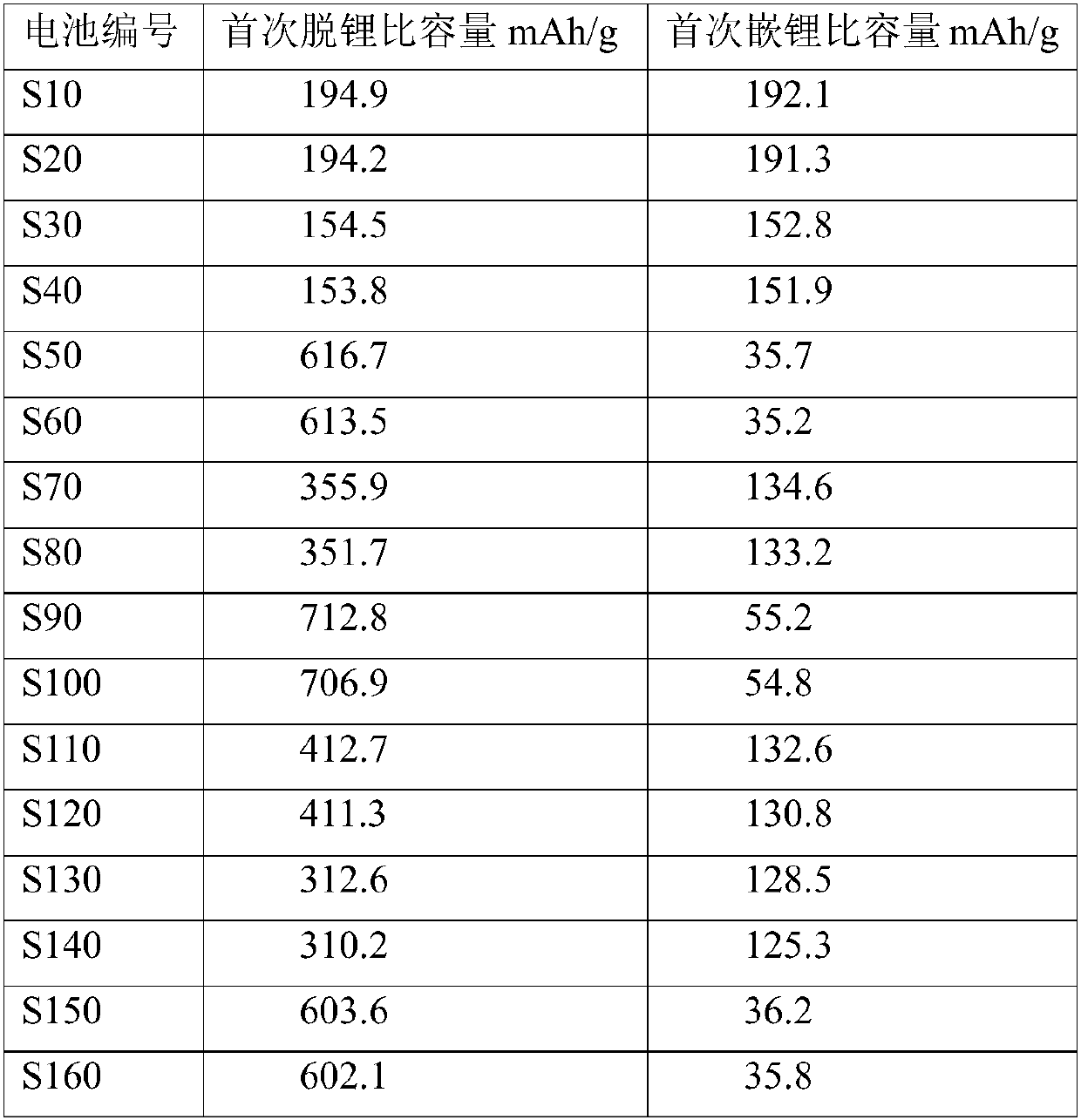

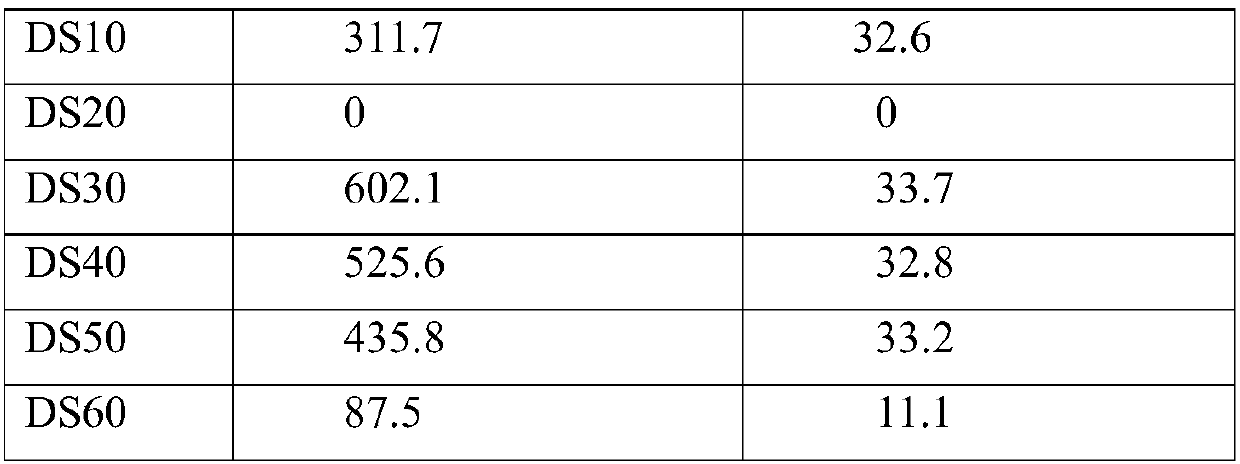

Examples

preparation example Construction

[0032] The present application also provides a method for preparing a positive electrode active material, wherein the method includes:

[0033] S1, the core material, carbon source and metal carbide are mixed and ground to obtain a precursor, the core material includes a lithium salt, and the lithium salt is selected from LiFeBO 3 , Li 2 FeSiO 4 , Li 5 FeO 4 , Li 6 CoO 4 , Li 6 MnO 4 , Li 2 NiO 2 and Li 2 CuO 2 one or more of

[0034] S2, drying the precursor prepared in S1, sintering at high temperature under an inert atmosphere, and cooling to obtain a positive electrode active material.

[0035] In the above preparation method, the in-situ carbon generated by the carbon source at high temperature can tightly cover the surface of the lithium salt, improve the conductivity of the lithium salt, and also protect the lithium salt; It can enter the lithium salt lattice at the lithium salt interface, and a small amount of metal ions in the lithium salt can be replaced...

Embodiment approach

[0052] Wherein, the separator can be selected from various separators used in lithium-ion batteries known to those skilled in the art, such as polyolefin microporous membrane (PP), polyethylene felt (PE), glass fiber felt or ultrafine glass fiber paper or PP / PE / PP. As a preferred embodiment, the separator is PP / PE / PP.

[0053] The preparation method of the lithium-ion battery provided by the present invention can be a method known to those skilled in the art. Generally speaking, the method includes winding the positive pole, the negative pole and the separator between the positive pole and the negative pole in sequence to form a pole core, and The pole core is put into the battery case, filled with electrolyte, and then sealed, wherein the winding and sealing methods are well known to those skilled in the art. The amount of electrolyte used is conventional. The electrolyte can also be replaced by one of all solid electrolytes, solid electrolytes or gel electrolytes.

[005...

Embodiment 1

[0057] LiFeBO with an average particle size of 100 nm 3 , glucose, and TiC nanoparticles with an average particle size of 2nm were mixed according to the mass ratio of 90:15:7, placed in a stirring ball mill, added ethanol, and wet mixed and ground for 6 hours; the precursor prepared by fully mixing and grinding was dried and placed in In a corundum crucible; put the crucible into a tube furnace, feed Ar gas, and start heating from room temperature at a heating rate of 5°C / min, then raise the temperature to 600°C and bake for 15h, then cool naturally to room temperature to obtain a carbon content of 3wt %, LiFeBO with a TiC content of 7wt% 3 / C+TiC composite, denoted as C1, in which the carbon and metal carbide coating has a thickness of 3 nm. The C1 sample was exposed to air for 1 day, and the obtained sample was marked as S1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com