Aluminum alloy material and surface treatment method and application thereof

A technology of aluminum alloy surface and treatment method, applied in metal material coating technology, surface polishing machine tools, metal processing equipment and other directions, can solve the problem of difficult polishing of wear-resistant coatings, etc. Improve the effect of polishing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

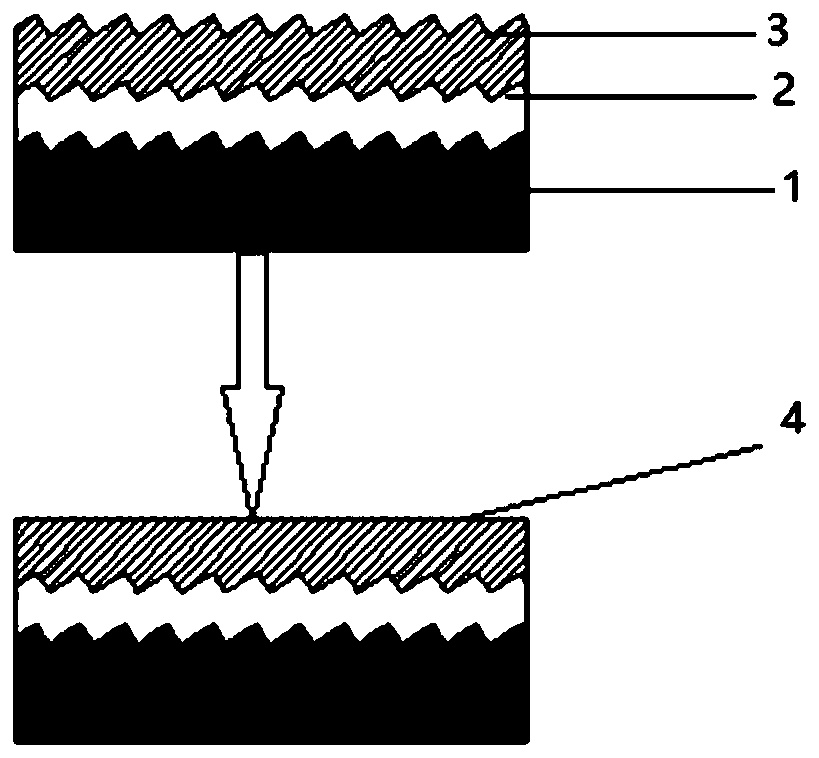

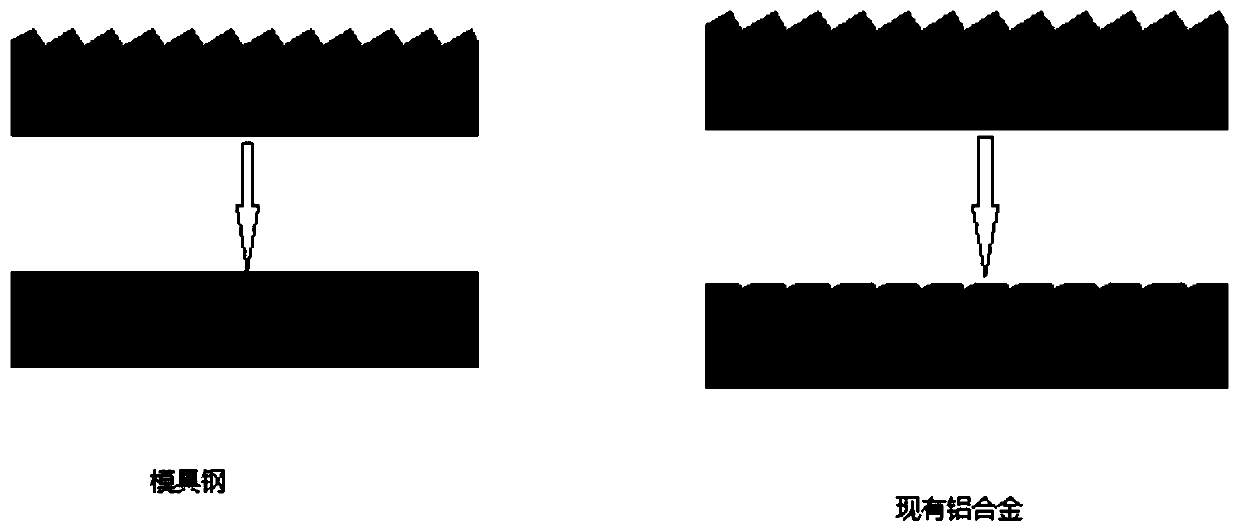

[0038] This embodiment provides a surface treatment method for aluminum alloy materials, such as figure 1 shown, including the following steps:

[0039] (1) Coarsening: by degreasing and cleaning the surface of the superhard aluminum alloy substrate 1, rough milling and grinding the surface requiring high gloss, and then performing surface roughening treatment by sandblasting to form a zigzag structure 2, the surface The roughness Ra reaches 3.2μm;

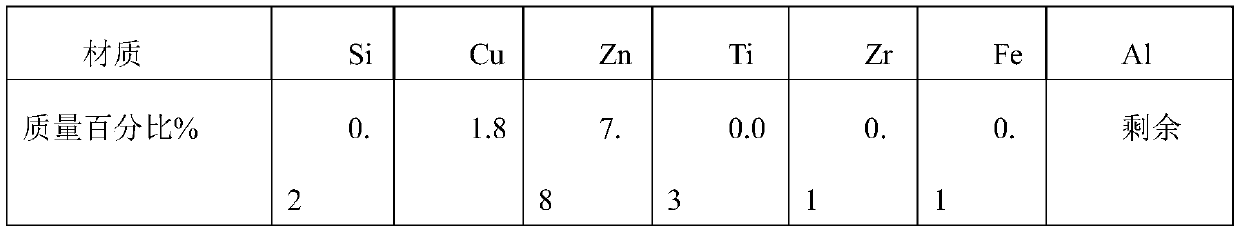

[0040] Table 1 Composition of superhard aluminum alloy matrix

[0041]

[0042] (2) Spraying: Put the aluminum alloy substrate after the surface sandblasting treatment into the thermal spraying room, first preheat the surface, in order to prevent the temperature from being too high, use compressed air to cool the sample surface during the entire spraying process;

[0043] The supersonic flame spraying method is used for spraying: through the high-speed and high-temperature flame generated in the combustion chamber by compress...

Embodiment 2

[0053] This embodiment provides a surface treatment method for an aluminum alloy material, comprising the following steps:

[0054] (1) Coarsening: by degreasing and cleaning the surface of the superhard aluminum alloy substrate, performing CNC rough milling and grinding treatment on the surface requiring high gloss, and then performing roughening treatment on the surface by sandblasting to form a zigzag structure with a rough surface The degree reaches 3.2μm;

[0055] Table 2 Composition of superhard aluminum alloy matrix

[0056]

[0057] (2) Spraying: Put the aluminum alloy substrate after the surface sandblasting treatment into the thermal spraying room, first preheat the surface, in order to prevent the temperature from being too high, use compressed air to cool the sample surface during the entire spraying process;

[0058] The supersonic flame spraying method is used for spraying: through the high-speed and high-temperature flame generated in the combustion chamber ...

Embodiment 3

[0067] This embodiment provides a surface treatment method for an aluminum alloy material, comprising the following steps:

[0068] (1) Coarsening: by degreasing and cleaning the surface of the superhard aluminum alloy substrate, performing CNC rough milling and grinding treatment on the surface requiring high gloss, and then performing roughening treatment on the surface by sandblasting to form a zigzag structure with a rough surface The degree reaches 3.2μm;

[0069] Table 3 Composition of superhard aluminum alloy matrix

[0070]

[0071] (2) Spraying: Put the aluminum alloy substrate after the surface sandblasting treatment into the thermal spraying room, first preheat the surface, in order to prevent the temperature from being too high, use compressed air to cool the sample surface during the entire spraying process;

[0072] Spraying by supersonic flame spraying method: through the high-speed and high-temperature flame generated in the combustion chamber by compressed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com