Cf/C-SiC-ZrC composite material and preparation method thereof

A composite material, c-sic-zrc technology, applied in the field of carbon fiber toughened ceramic matrix composite materials, can solve the problems of brittle fracture, limited application, lack of plastic deformation of ceramic materials, etc., to improve fracture toughness and strength, and improve fracture toughness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

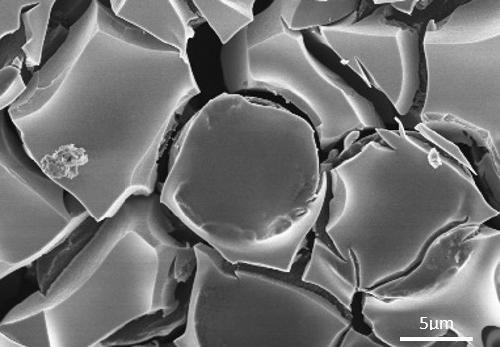

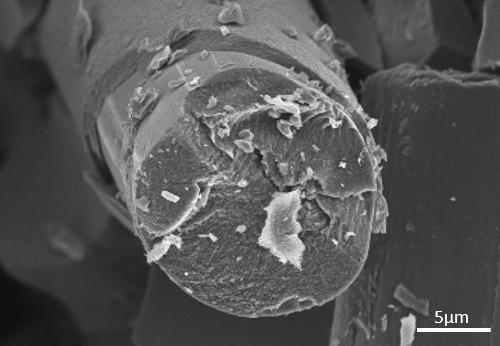

[0035] Using T700 12K carbon fiber from Toray Corporation of Japan as the raw material, the volume fraction is 40% and the initial density is 0.7 g / cm through three-dimensional weaving 3 The prefabricated carbon fiber woven prefabricated body is degummed at 900 ℃, and the prefabricated body after the degummed treatment is prepared in a chemical vapor deposition furnace for pyrolytic carbon PyC interface layer. The gas source is propane, and the flow rate is controlled at 2 L / min, the dilution gas is Ar, the flow rate is controlled at 4 L / min, the deposition temperature is 1000 °C, the deposition time is 24 h, and the density is 0.9 g / cm 3 carbon fiber preforms.

[0036] Using xylene as a solvent, polycarbosilane and polycarbozircones are mixed according to a mass ratio of 1:3, stirred until polycarbosilanes and polycarbozircones are completely dissolved in xylene solvent, and then the density is 0.9 g / cm 3 The carbon fiber prefabricated body was immersed in the mixed solutio...

Embodiment 2

[0039]Using T700 12K carbon fiber from Toray Corporation of Japan as the raw material, the volume fraction is 50% and the initial density is 1.1 g / cm through three-dimensional weaving. 3 The prefabricated carbon fiber braided prefabricated body was degummed at 950 °C, and the PyC interface layer was prepared in a chemical vapor deposition furnace after the degummed prefabricated body. The gas source was propane, and the flow rate was controlled at 3 L / min, the dilution gas is Ar, the flow rate is controlled at 3 L / min, the deposition temperature is 950 °C, the deposition time is 36 h, and the density is 1.4 g / cm 3 carbon fiber preforms.

[0040] Using xylene as a solvent, polycarbosilane and polycarbozircones were prepared in a mass ratio of 1:1, mixed and then magnetically stirred until polycarbosilanes and polycarbozircones were completely dissolved in xylene solvent, Then set the density to 1.4g / cm 3 The carbon fiber prefabricated body was immersed in the mixed solution,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com