Soft magnetic composite material with high saturation magnetic flux density and high strength and preparation method thereof

A soft magnetic composite material and magnetic flux density technology, applied in the fields of inorganic material magnetism, inductance/transformer/magnet manufacturing, electrical components, etc., can solve the problems of unstable electromagnetic performance, poor process repeatability, and deviation of soft magnetic composite materials , to meet the requirements of use, high magnetic flux density, reduce the effect of forming stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

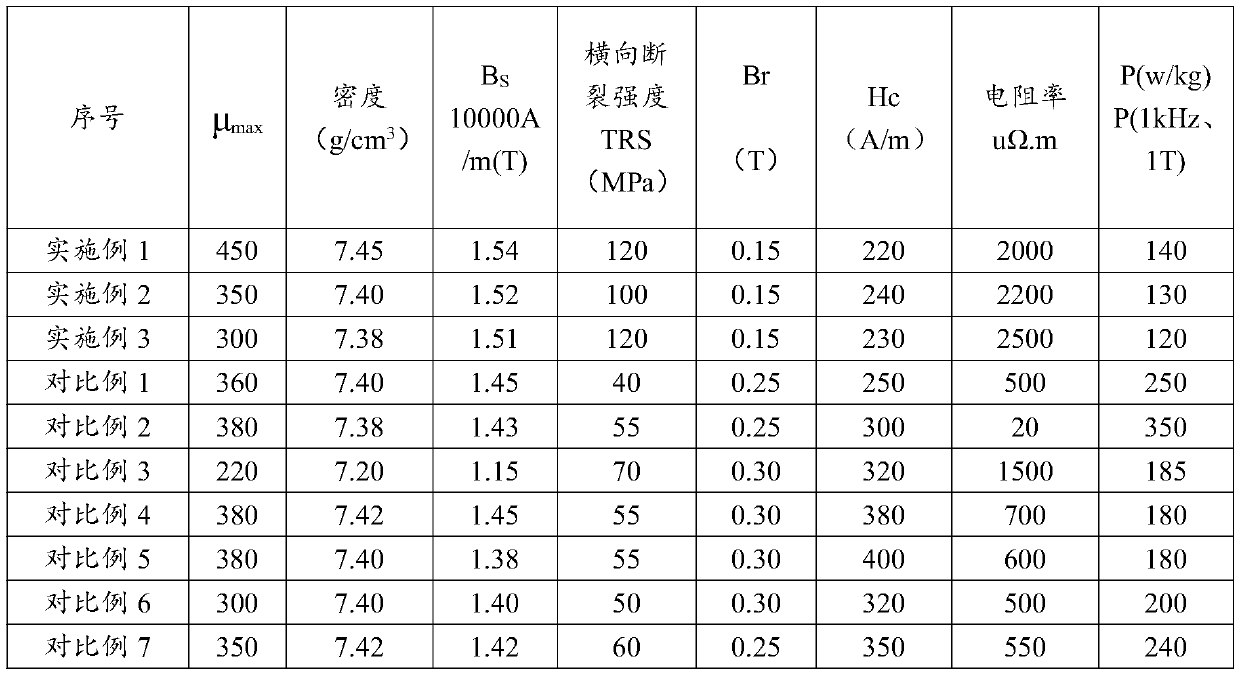

Examples

Embodiment 1

[0029] A method for preparing a high saturation magnetic flux density, high-strength soft magnetic composite material, comprising the following steps:

[0030] Step 1: Take Laiwu water atomized iron powder (iron powder particle size 80-200um, iron powder purity > 99.0%), add 100 grams to 1000 ml acetone;

[0031] Step 2: Add 10 ml of 1wt% orthophosphoric acid to the solution in step 1, and mechanically stir for 30 minutes; evaporate to dryness at 70-90°C for 2 hours, and pass through a 80-mesh sieve to obtain coated powder;

[0032] Step 3: put the above-mentioned coating powder and 0.1 g of calcium carbonate into a ball mill and mill for 20 minutes to obtain double-coated insulation-coated iron powder;

[0033] Step 4: Add 0.2 g of zinc stearate to the above-mentioned insulating coated iron powder and mix evenly;

[0034] Step 5: Heat the mold to 120°C, add the mixture in step 4 to the mold, press with 1000MPa pressure, and lubricate the mold wall;

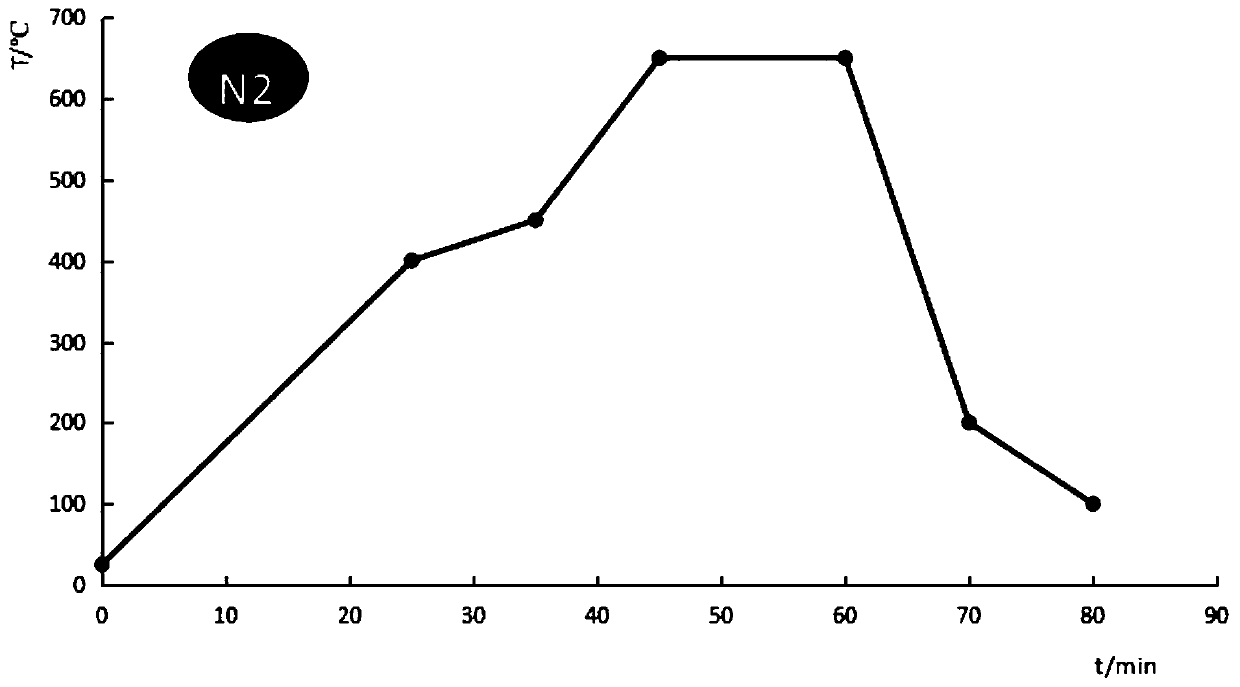

[0035] Step 6: Place th...

Embodiment 2

[0037] A method for preparing a high saturation magnetic flux density, high-strength soft magnetic composite material, comprising the following steps:

[0038] Step 1: Take ABC100.30 (iron powder particle size 80-200um, iron powder purity > 99.0%), add 100 grams into 1000 ml acetone;

[0039] Step 2: Add 10 ml of 2wt% orthophosphoric acid to the solution in step 1, and mechanically stir for 30 minutes; evaporate to dryness at 70-90°C for 2 hours, and pass through a 80-mesh sieve to obtain coated powder;

[0040] Step 3: put the above-mentioned coating powder and 0.3 g of calcium carbonate into a ball mill and mill for 20 minutes to obtain double-coated insulation-coated iron powder;

[0041] Step 4: Add the above insulating coated iron powder to 0.4 g of amide wax and mix evenly;

[0042] Step 5: Heat the mold to 120°C, add the mixture of step 4 into the mold, press with 800MPa pressure, and lubricate the mold wall to form;

[0043] Step 6: Place the pressed magnetic ring in...

Embodiment 3

[0045] A method for preparing a high saturation magnetic flux density, high-strength soft magnetic composite material, comprising the following steps:

[0046] Step 1: Take reduced iron powder (iron powder particle size 80-200um, iron powder purity > 99.0%), add 100 grams into 1000 ml of acetone;

[0047] Step 2: Add 10 ml of 5wt% orthophosphoric acid to the solution in step 1, and mechanically stir for 30 minutes;

[0048] Step 2: Add 10 ml of 5wt% orthophosphoric acid to the solution in step 1, and mechanically stir for 30 minutes; evaporate to dryness at 70-90°C for 2 hours, and pass through a 80-mesh sieve to obtain coated powder;

[0049] Step 3: put the above-mentioned coating powder and 0.6 g of calcium carbonate into a ball mill and mill for 20 minutes to obtain double-coated insulating-coated iron powder;

[0050] Step 4: Add the above insulating coated iron powder to 0.6 g of amide wax and mix evenly;

[0051] Step 5: Heat the mold to 80°C, add the mixture of step ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com