Low-viscosity fucosan and high-temperature high-pressure enzymatic coupling preparation method thereof

A technology of viscosity fucoidan, high temperature and high pressure, applied in lyase, fermentation, etc., can solve the problems of low sulfate retention and low enzymatic hydrolysis efficiency, and achieve the effect of low cost, high hydrolysis efficiency and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Example 1: Fucoidan prehydrolysis process optimization

[0036] In this example, by comparing the hydrolysis effect of fucoidan by acid method, oxidation method and high temperature and high pressure treatment technology, the best pre-hydrolysis method is selected based on the retention of sulfuric acid group when the viscosity value of the polysaccharide solution drops by about 20%. process conditions.

[0037] (1) Experimental method

[0038] A. Acid hydrolysis: Prepare 2wt% aqueous solution of high-polymeric fucoidan, and add HCl solution to make the final concentrations 0, 0.05mol / L, 0.1mol / L and 0.2mol / L respectively, and then Hydrolysis was carried out with or without ultrasonic (frequency 40kHz) auxiliary technology, and the change of viscosity value during the hydrolysis process was measured every 15 minutes. After the reaction, the pH value of the hydrolyzate was adjusted to neutrality, and then passed through an 8kDa ultrafiltration membrane to remove the fa...

Embodiment 2

[0045] Example 2: Hydrolysis effect of fucoidan lyase on pretreated fucoidan

[0046] In this example, the fucoidan lyase extracted from scallop viscera or abalone viscera was used as a tool enzyme to further hydrolyze the high-temperature and high-pressure pre-hydrolyzed fucoidan solution obtained in Example 1, and the viscosity value of the polysaccharide solution was changed. Observe the hydrolysis effect as an indicator.

[0047] (1) Experimental method

[0048] A. Preparation of fucoidan lyase: After the fresh scallop viscera or abalone viscera are broken and homogenized by a homogenizer, the resulting homogenate is added with pH=7.0 at a ratio of 1:5 (g / mL). Phosphate buffer solution, leaching overnight at 4°C; refrigerated centrifugation (8000r / min, 20min), collecting the supernatant; adding ammonium sulfate to the supernatant to make the ammonium sulfate concentration 30% (w / v), And leave it to react at 4°C for 2h, refrigerate and centrifuge (8000r / min, 15min), colle...

Embodiment 3

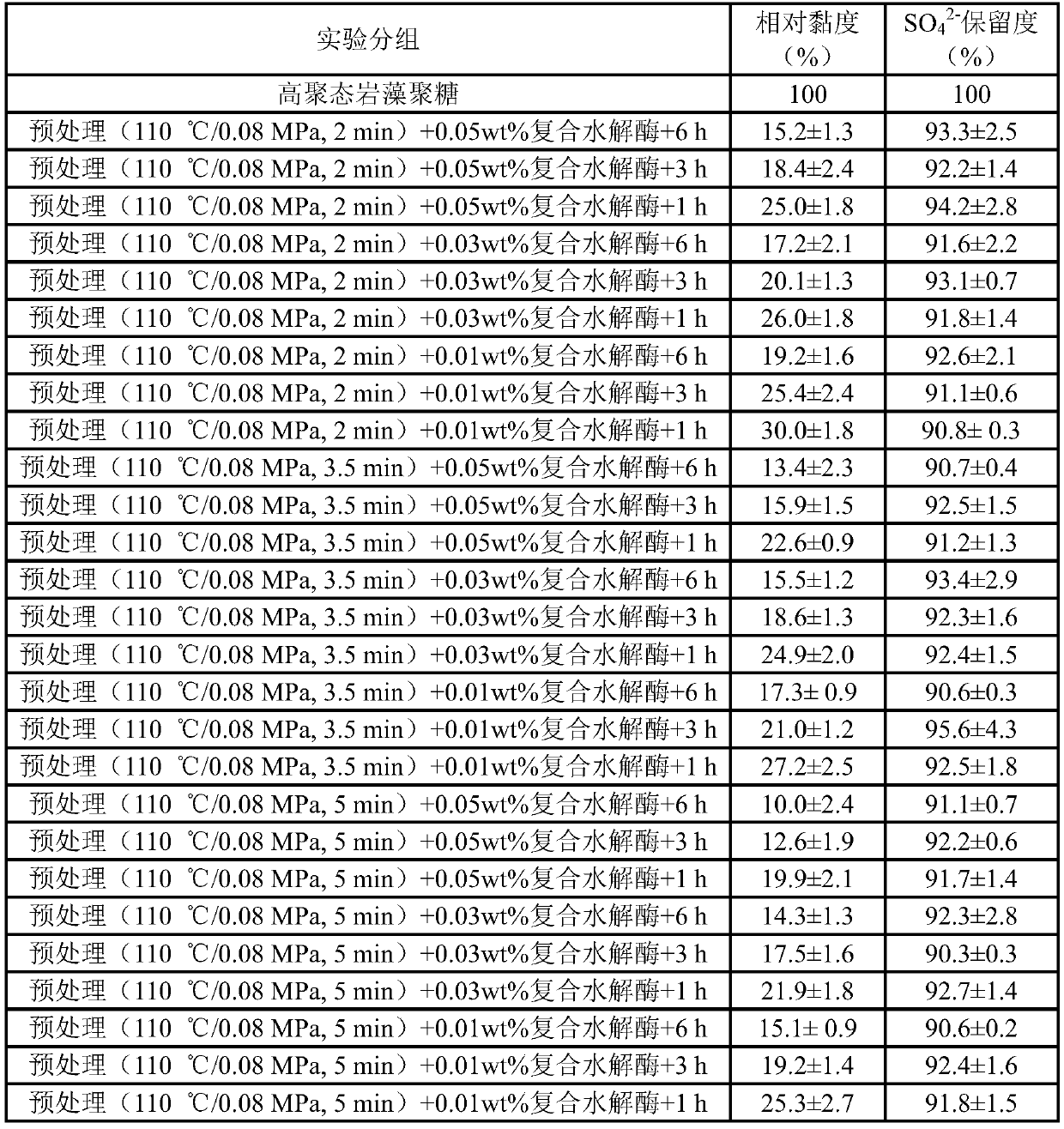

[0054] Embodiment 3: the formula design of compound hydrolase

[0055] (1) Experimental method

[0056] A. The preparation of compound hydrolase: the fucoidan lyase that embodiment 2 obtains and β-galactosidase (30000U / g), β-glucosidase (30000U / g), alkaline protease (20000U / g) g) and pectinase (8000U / g) are compounded according to the weight ratio of 6:1:1:1:1 to form a composite hydrolase.

[0057] B. Hydrolysis effect: Dissolve high-polymeric fucoidan in deionized water to obtain a 2wt% aqueous solution of high-polymeric fucoidan; use the preferred high-temperature and high-pressure pretreatment conditions of Example 1 (110°C / 0.08MPa, 2-5 minutes) to pretreat the high-polymer fucoidan aqueous solution; after cooling to room temperature, add complex hydrolase to the pretreated fucoidan solution so that the final concentration is 0.01-0.05wt%, at room temperature After hydrolysis for 1-6 hours, analyze the viscosity change of the fucoidan solution.

[0058] C. Drying: spray...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com