Method for increasing methane yield by assisting anaerobic microorganism treatment through electrolysis

An anaerobic microorganism and methane technology, applied in the field of anaerobic biological treatment, to achieve the effect of reducing power, increasing hydrolysis rate, and reducing dilution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

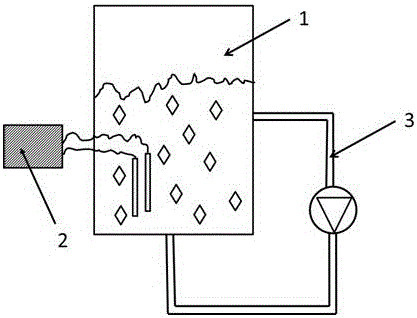

[0038] A kind of device that utilizes above-mentioned method to produce methane such as figure 1 As shown, on the anaerobic fermentation reactor 1, an electrolysis device 2 is connected, and a circulation loop 3 is connected at both ends of the anaerobic fermentation reactor 1. The electrolysis device 2 adopts scaly graphite as an electrode, and the electrolysis voltage is 2V. The current density is 0.003A / cm 2 .

Embodiment 2

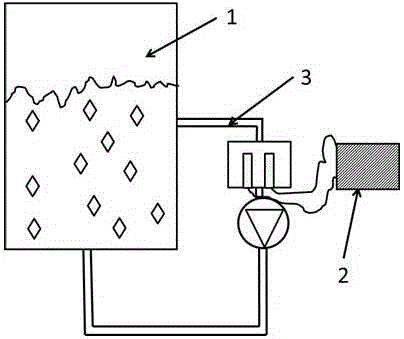

[0040] A kind of device that utilizes above-mentioned method to produce methane such as figure 2 As shown, a circulation loop 3 is connected to both ends of the anaerobic fermentation reactor 1, and an electrolysis device 2 is arranged on the circulation loop 3. The electrolysis device 2 uses spherical graphite as the electrode, the electrolysis voltage is 6V, and the current density is 0.005A / cm 2 . The electrolysis device can be an ordinary electrolysis cell or a biological electrolysis cell.

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com