Modified film cloth and preparation method thereof

A membrane cloth and modification technology, which is applied in coatings, biocide-containing paints, antifouling/underwater coatings, etc., can solve the problem of inability to guarantee the anti-pollution and antibacterial ability of membrane cloth, reduce the toughness and other mechanical properties of membrane cloth , Unable to achieve the mechanical properties of the membrane cloth, etc., to achieve the effect of ensuring anti-pollution and antibacterial ability, improving anti-pollution and antibacterial ability, and improving elasticity and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

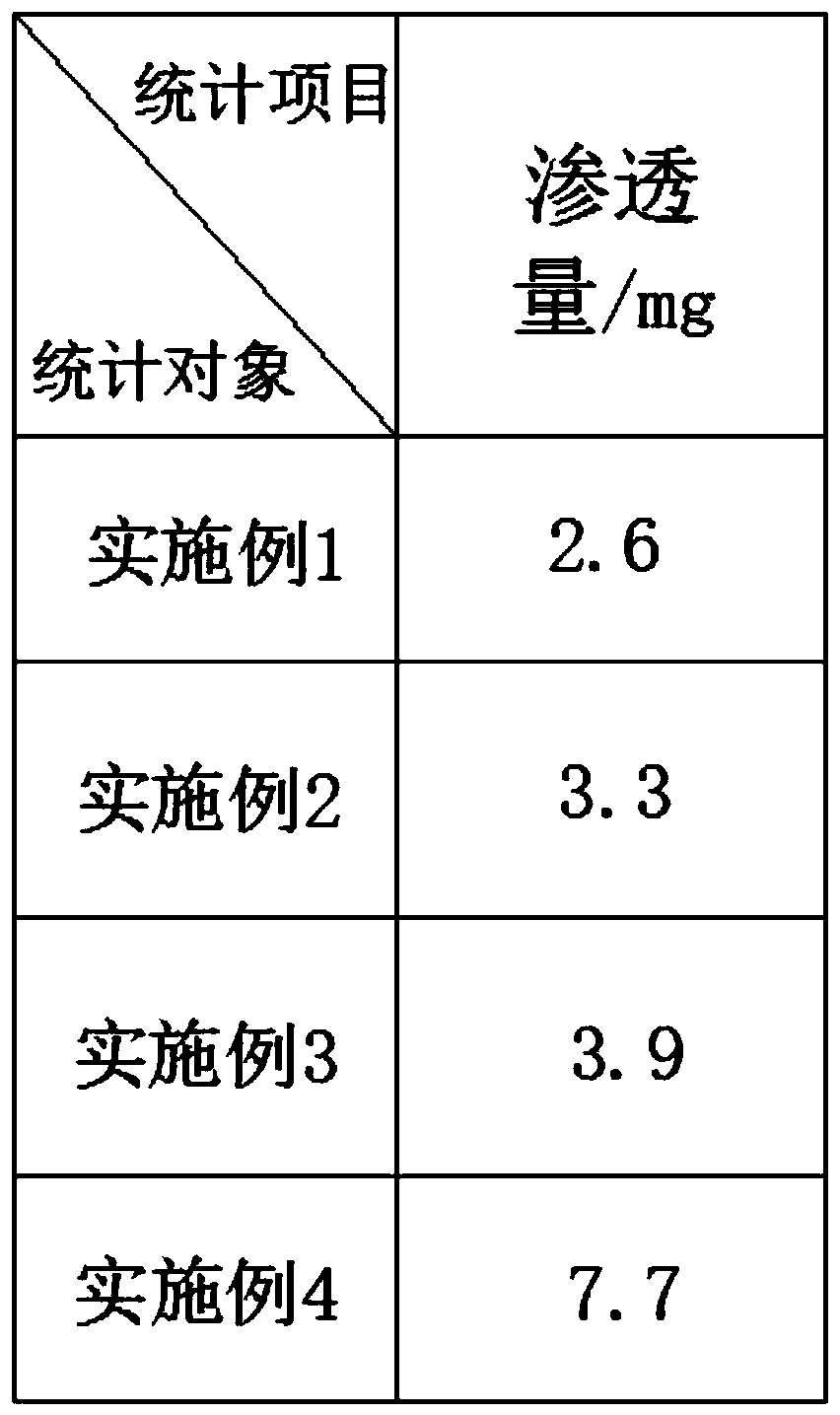

Embodiment 1

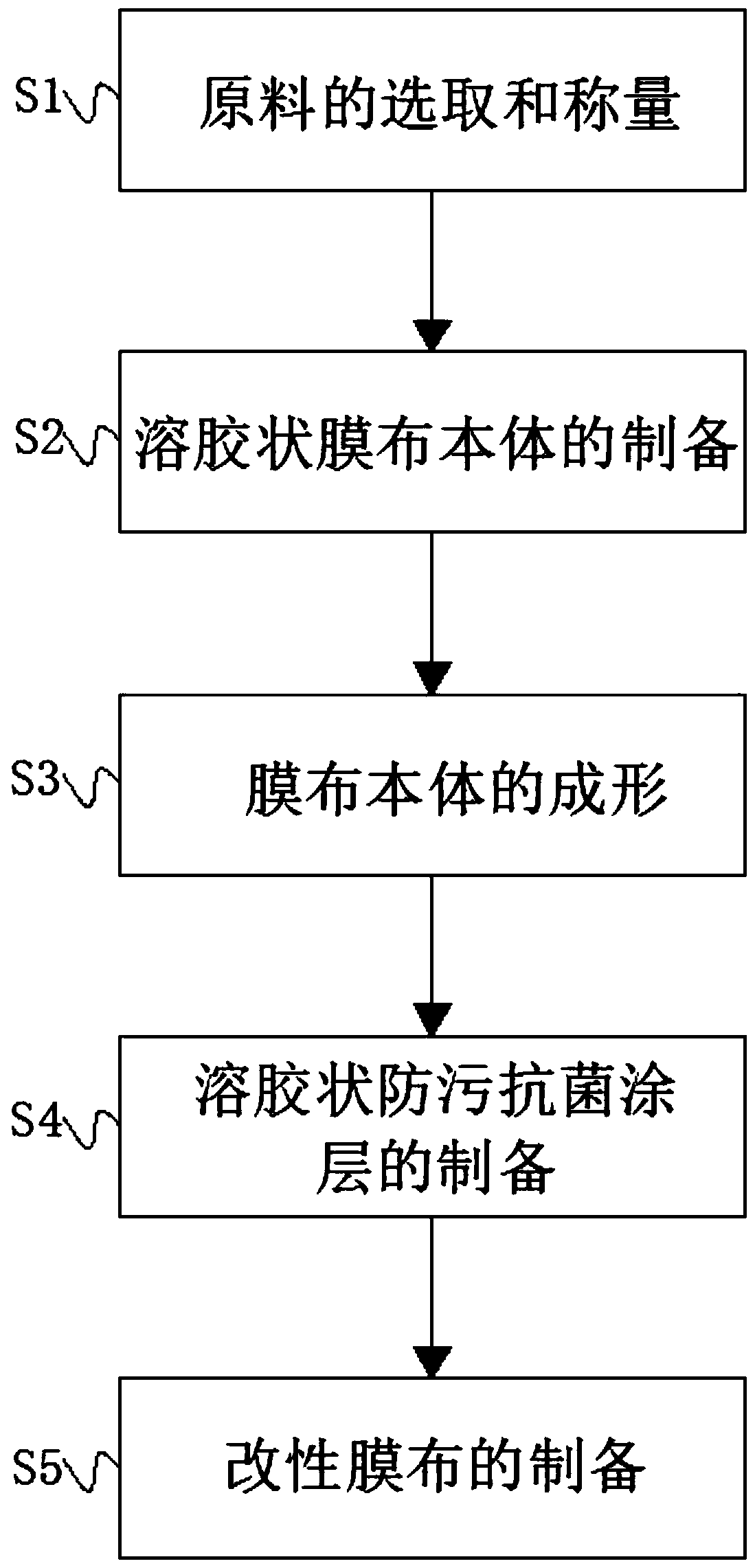

[0032] S1. Selection and weighing of raw materials: First, measure 35 parts of natural plant fibers, 15 parts of chitin, 15 parts of chitosan, 3 parts of gelling agent, and 3 parts of toughening agent by weighing equipment. , 2 parts of flame retardant, 2 parts of antioxidant, 55 parts of methyl phenyl silicone resin, 3 parts of mildew inhibitor, 2 parts of silver chloride powder and 3 parts of cross-linking agent, and poured the measured components into It is stored in a storage tank and is waiting to be used. The natural plant fiber is a combination of ramie fiber, hemp fiber, flax fiber and jute fiber, and the gelling agent is aloe vera gel, sclerotium gum, guar gum, carrageenan, gellan The composition of gum, pectin, carrageenan and konjac gum, the flame retardant is the composition of antimony trioxide, ferric oxide, zinc oxide and zinc borate;

[0033] S2, the preparation of the sol-like film cloth body: pour the natural plant fiber, chitin, chitosan, gelling agent, toughe...

Embodiment 2

[0038] S1. Selection and weighing of raw materials: First, measure 30 parts of natural plant fibers, 10 parts of chitin, 10 parts of chitosan, 1 part of gelling agent, and 1 part of toughening agent in corresponding weight proportions by weighing equipment. , 1 part flame retardant, 1 part antioxidant, 50 parts methyl phenyl silicone resin, 1 part mildew inhibitor, 1 part silver chloride powder and 1 part crosslinking agent, and pour the measured components into The storage tank is stored for use, and the natural plant fiber is the composition of ramie fiber and jute fiber, the gelling agent is the composition of aloe vera gum and konjac gum, and the flame retardant is the composition of antimony trioxide and zinc borate;

[0039] S2, the preparation of the sol-like film cloth body: pour the natural plant fiber, chitin, chitosan, gelling agent, toughening agent, flame retardant and antioxidant measured in step S1 into the mixing mixer in turn, and rotate at a rotating speed. U...

Embodiment 3

[0044] S1. Selection and weighing of raw materials: First, measure 40 parts of natural plant fibers, 20 parts of chitin, 20 parts of chitosan, 5 parts of gelling agent, and 5 parts of toughening agent in corresponding weight proportions by weighing equipment. , 3 parts of flame retardant, 3 parts of antioxidant, 60 parts of methyl phenyl silicone resin, 5 parts of antifungal agent, 3 parts of silver chloride powder and 5 parts of cross-linking agent, and poured the measured components into It is stored in the storage tank for use, the natural plant fiber is ramie fiber, the gelling agent is aloe vera gel, and the flame retardant is antimony trioxide;

[0045] S2, the preparation of the sol-like film cloth body: pour the natural plant fiber, chitin, chitosan, gelling agent, toughening agent, flame retardant and antioxidant measured in step S1 into the mixing mixer in turn, and rotate at a rotating speed. Under the condition of 600r / min and temperature of 33℃, stir for 3h until ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com