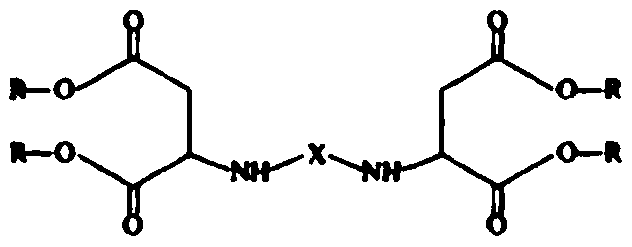

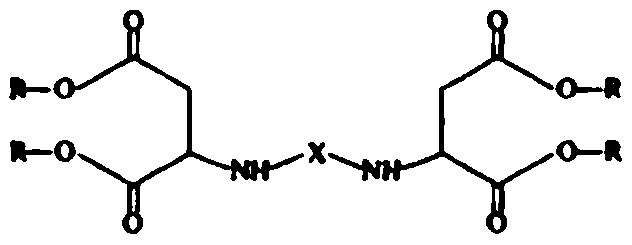

Aspartate polyurea adhesive and preparation method thereof

A technology of aspartic acid ester and adhesive, which is applied in the direction of polyurea/polyurethane adhesive, adhesive, non-polymer adhesive additive, etc., which can solve the problem of restricting use, reducing the bonding effect of substrates, affecting product appearance or Sealing performance and other issues to achieve the effect of improving appearance, strong adhesion, and excellent corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

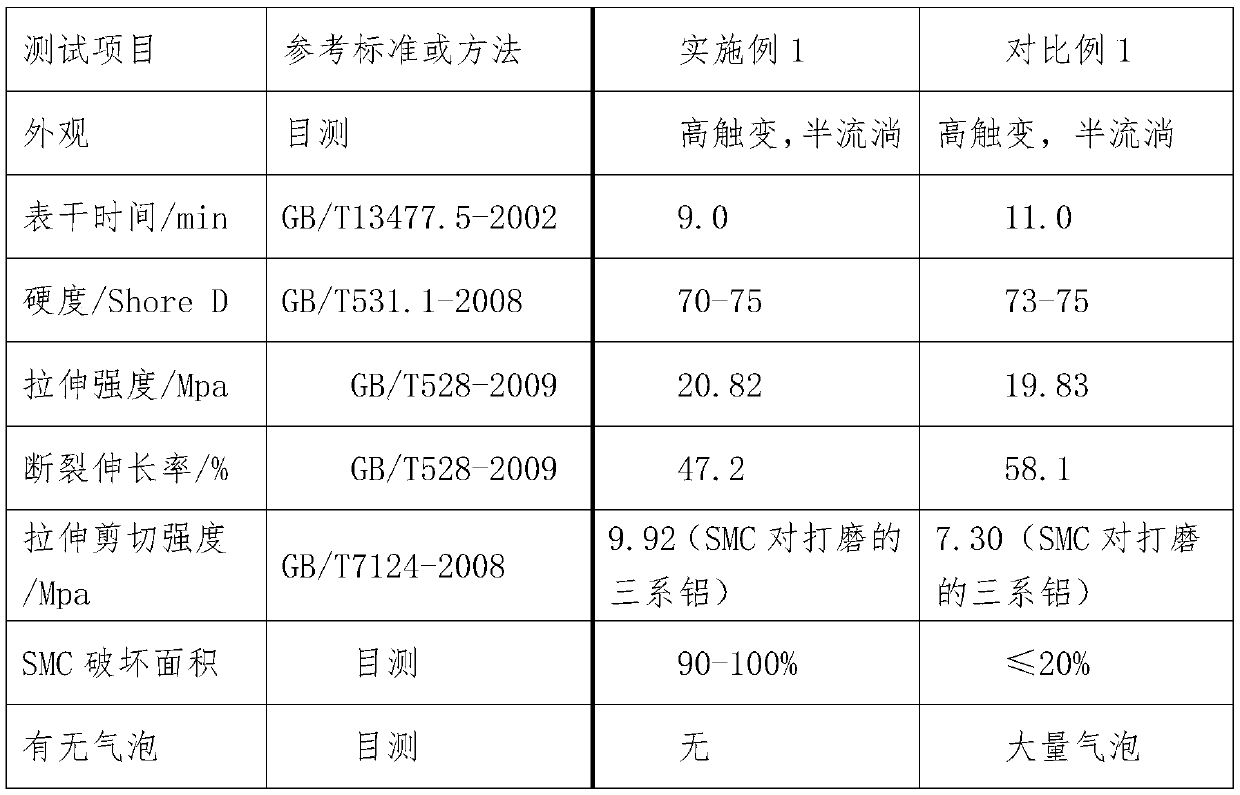

Examples

Embodiment 1

[0030] In the embodiment of the present invention, an aspartic acid ester type polyurea adhesive, the mass ratio of component A to component B is 245:100, component A includes NH1420, fumed silica, defoamer WE-D980 , catalyst DBTDL, calcium carbonate, wherein, NH1420, fumed silica, defoamer WE-D980, catalyst DBTDL, calcium carbonate mass ratio is 200:2:0.4:0.02:200, B component includes N100.

[0031] The preparation method of aspartic acid ester type polyurea adhesive described in the present embodiment, the steps are as follows:

[0032] 1) take each raw material by proportioning;

[0033] 2) Preparation of component A: Add NH-1420, fumed silica, defoamer WE-D980, and catalyst DBTDL in sequence in a dry and clean reaction bottle equipped with a stirring device and a vacuum device, and set stirring after the addition is complete The speed is 500-800 rpm, the vacuum degree is -0.098Mpa, after mixing evenly, add calcium carbonate, continue to stir and vacuumize after the addit...

Embodiment 2

[0043] In the embodiment of the present invention, an aspartic acid ester type polyurea adhesive, the mass ratio of A component to B component is 100:110, A component includes NH1420, defoamer BYK-066N, wherein, NH1420, defoamer Foaming agent BYK-066N mass ratio is 200:1, B component includes N3900, polyether NJ-220, thinner TXIB, wherein, the mass ratio of N3900, polyether NJ-220, thinner TXIB is 120:80:20 .

[0044] The preparation method of aspartic acid ester type polyurea adhesive described in the present embodiment, the steps are as follows:

[0045] 1) take each raw material by proportioning;

[0046] 2) Preparation of component A: In a dry and clean reaction bottle equipped with a stirring device, add NH1420 and defoamer BYK-066N in sequence, and stir evenly after adding, to prepare component A;

[0047] 3) Preparation of component B: Add N3900 into a dry and clean three-necked reaction flask equipped with a heating device, a stirring device, and a vacuuming device, ...

Embodiment 3

[0056] In the embodiment of the present invention, an aspartic acid ester type polyurea adhesive, the mass ratio of A component to B component is 100:30, A component includes NHQ6220, NHQ620, plasticizer DI, defoamer WE- The mass ratio of D980, silane coupling agent A-1120, NHQ6220, NHQ620, plasticizer DI, defoamer WE-D980, silane coupling agent A-1120 is 140:60:20:1:2, the B Components include N3900.

[0057] The preparation method of aspartic acid ester type polyurea adhesive described in the present embodiment, the steps are as follows:

[0058] 1) take each raw material by proportioning;

[0059] 2) Preparation of component A: Add NHQ6220, NHQ620, plasticizer DI, defoamer WE-D980, and silane coupling agent A-1120 in sequence in a dry and clean reaction bottle equipped with a stirring device and a vacuum device After the addition, set the stirring speed to 500-800 rpm, the vacuum degree to -0.098Mpa, and mix evenly to obtain component A;

[0060] 3) Preparation of compon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Functional group degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com