Special bio-organic fertilizer for beta vulgaris and preparation method of bio-organic fertilizer

A bio-organic fertilizer and sugar beet technology, which is applied in the preparation of organic fertilizers, the treatment of bio-organic parts, organic fertilizers, etc., can solve the problems of hindered growth of crops, poor ventilation, and pollution of drinking water sources, etc., to increase root yield and sugar content efficiency, prevent fungal and bacterial infection, improve enzyme activity and immunity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

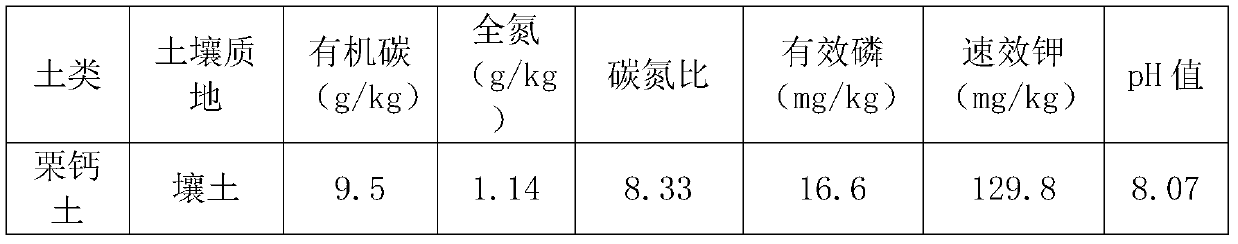

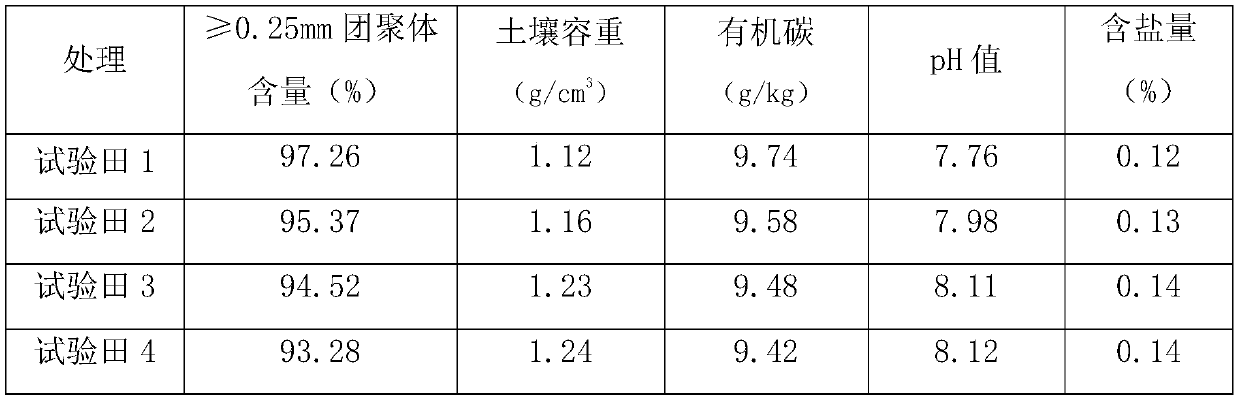

[0034] Embodiment 1: A special bio-organic fertilizer for beet, its components include 25 parts of beet tail root in parts by mass, 25 parts of sugar filter mud mixture, 20 parts of cattle and sheep manure, 3 parts of activated biological fermentation liquid, 3 parts of synergist , 8 parts of yeast urea sulfate concentrate, 0.2 part of concentrated bacteria powder.

[0035] Wherein, the sugar filter mud mixture includes the following components by mass: 3 parts of sugar filter mud, 2 parts of humic acid, and 1 part of furfural residue; humic acid and furfural residue can reduce the pH value in the sugar filter mud, making the sugar filter mud The pH value of the mixture is 7.5-8.5. At the same time, humic acid can also improve the soil, and have a complex reaction with heavy metal ions that are difficult to degrade in the soil, reducing the heavy metal content in the soil. It is suitable for planting sugar beets; the activated biological fermentation liquid includes the follow...

Embodiment 2

[0036] Embodiment 2: A special biological organic fertilizer for sugar beet, its components include 30 parts of sugar beet tail root in parts by mass, 35 parts of sugar filter mud mixture, 30 parts of cattle and sheep manure, 5 parts of activated biological fermentation liquid, 5 parts of synergist parts, 10 parts of yeast urea sulfate concentrate, and 0.5 parts of concentrated bacterial powder.

[0037] Wherein, the sugar filter mud mixture includes the following components by mass: 5 parts of sugar filter mud, 3 parts of humic acid, and 2 parts of furfural residue; humic acid and furfural residue can reduce the pH value in the sugar filter mud, making the sugar filter mud The pH value of the mixture is 7.5-8.5. At the same time, humic acid can also improve the soil, and have a complex reaction with heavy metal ions that are difficult to degrade in the soil, reducing the heavy metal content in the soil. It is more suitable for planting sugar beets; the activated biological fe...

Embodiment 3

[0038] Embodiment 3: A kind of special bio-organic fertilizer for sugar beets, its components include 27 parts of sugar beet tail roots in parts by mass, 27 parts of sugar filter mud mixture, 25 parts of cattle and sheep manure, 4 parts of activated biological fermentation liquid, 4 parts of synergists parts, 9 parts of yeast urea sulfate concentrate, and 0.4 parts of concentrated bacterial powder.

[0039] Wherein, the sugar filter mud mixture includes the following components by mass: 4 parts of sugar filter mud, 2.5 parts of humic acid, and 1.5 parts of furfural residue; humic acid and furfural residue can reduce the pH value in the sugar filter mud, making the sugar filter mud The pH value of the mixture is 7.5-8.5. At the same time, humic acid can also improve the soil, and have a complex reaction with heavy metal ions that are difficult to degrade in the soil, reducing the heavy metal content in the soil. It is more suitable for planting sugar beets; the activated biolog...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com