High-hardness waterborne acrylic acid modified alkyd resin baking enamel

A water-based acrylic and alkyd resin technology, applied in coatings, fireproof coatings, polyester coatings, etc., can solve problems such as low gloss, poor hardness, and limited use range, achieve good gloss, enhance apparent hardness and gloss, The effect of improving dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

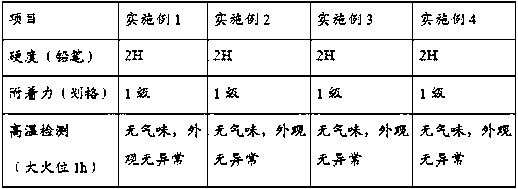

Examples

Embodiment 1

[0020] A high-hardness water-based acrylic modified alkyd resin baking varnish. The ratio of components in the high-hardness water-based acrylic modified alkyd resin baking varnish is as follows: benzoic acid modified alkyd resin: 10, water-based acrylic modified alkyd resin Alkyd resin: 25, epoxy modified water-based acrylic resin: 10, amino resin: 8, water-based colorant: 8, deionized water: 5, n-butanol: 4, nano zinc oxide powder: 5, cellulose Powder: 1, chelating titanate coupling agent: 0.3, fumed silica: 2, zinc phosphate: 0.2, organophosphate: 1, polyurethane: 0.5, modified polysiloxane: 0.2, triethylamine : 0.1, wetting and dispersing agent: 0.5, leveling agent: 0.1. The alkyd resin matrix used in the benzoic acid modified alkyd resin has an oil content of 30% to 40%. The modified matrix of the water-based acrylic modified alkyd resin is a medium alkyd resin with an oil content of 40% to 60%. The water-based acrylic modified alkyd resin is in the state of emulsion, w...

Embodiment 2

[0029] A high-hardness water-based acrylic modified alkyd resin baking varnish. The ratio of components in the high-hardness water-based acrylic modified alkyd resin baking varnish is as follows: benzoic acid modified alkyd resin: 15, water-based acrylic modified alkyd resin Alkyd resin: 40, epoxy modified water-based acrylic resin: 15, amino resin: 12, water-based color paste: 15, deionized water: 10, n-butanol: 7, nano-zinc oxide powder: 10, cellulose Powder: 5, chelating titanate coupling agent: 0.7, fumed silica: 5, zinc phosphate: 0.5, organophosphate: 3, polyurethane: 1.5, modified polysiloxane: 0.5, triethylamine : 0.5, wetting and dispersing agent: 1.5, leveling agent: 0.3. The alkyd resin matrix used in the benzoic acid modified alkyd resin has an oil content of 30% to 40%. The modified matrix of the water-based acrylic modified alkyd resin is a medium alkyd resin with an oil content of 40% to 60%. The water-based acrylic modified alkyd resin is in the state of emul...

Embodiment 3

[0038] A high-hardness water-based acrylic modified alkyd resin baking varnish. The ratio of components in the high-hardness water-based acrylic modified alkyd resin baking varnish is as follows: benzoic acid modified alkyd resin: 12, water-based acrylic modified alkyd resin Alkyd resin: 35, epoxy modified water-based acrylic resin: 10, amino resin: 10, water-based color paste: 11, deionized water: 10, n-butanol: 7, nano-zinc oxide powder: 8, cellulose Powder: 3, chelating titanate coupling agent: 0.7, fumed silica: 3, zinc phosphate: 0.3, organophosphate: 2, polyurethane: 1, modified polysiloxane: 0.4, triethylamine : 0.5, wetting and dispersing agent: 1, leveling agent: 0.3. The alkyd resin matrix used in the benzoic acid modified alkyd resin has an oil content of 30% to 40%. The modified matrix of the water-based acrylic modified alkyd resin is a medium alkyd resin with an oil content of 40% to 60%. The water-based acrylic modified alkyd resin is in the state of emulsion,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com