Radome material and preparation method thereof

A radome and fiber cloth technology, applied in the field of radome materials and their preparation, can solve the problems of high cost and high processing cost of composite materials, and achieve the effects of light weight, reduced raw material usage and cost, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

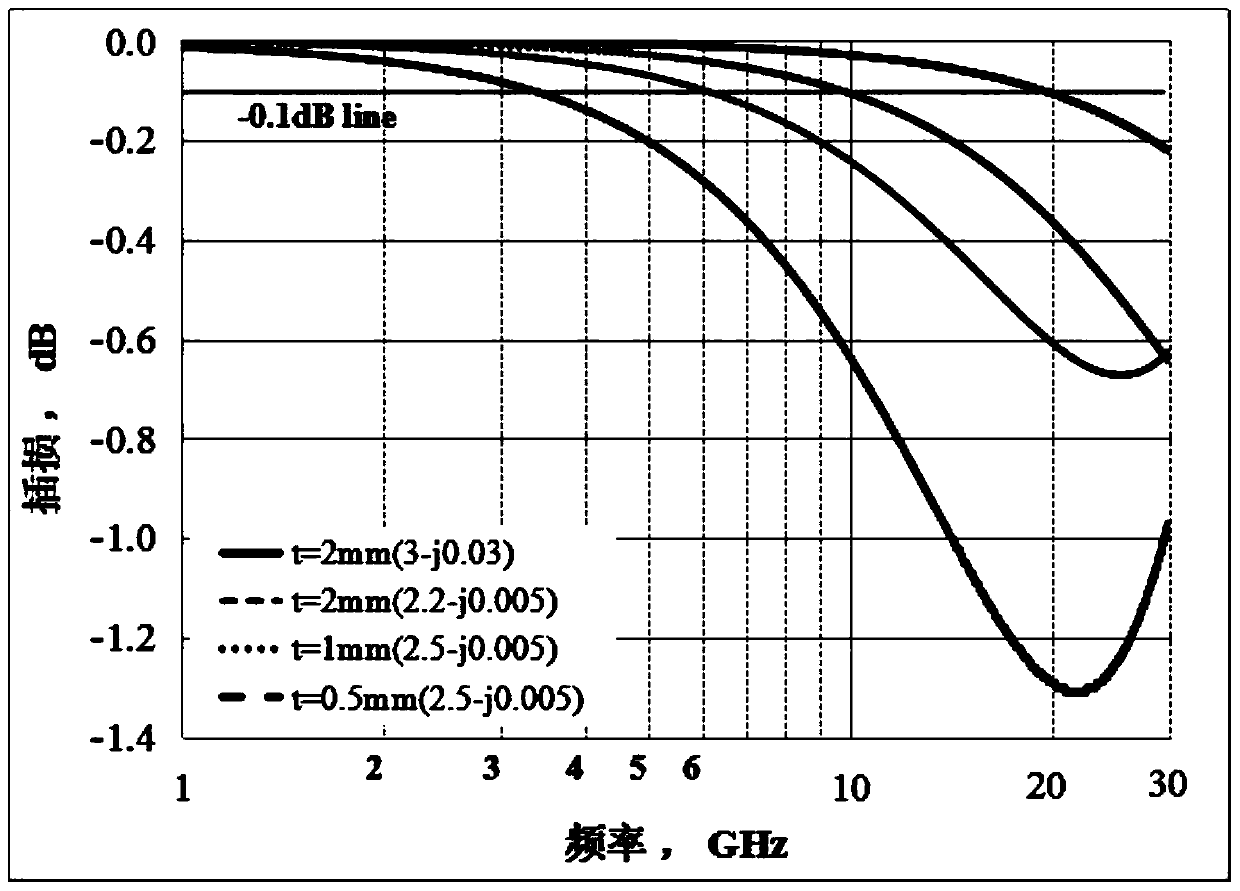

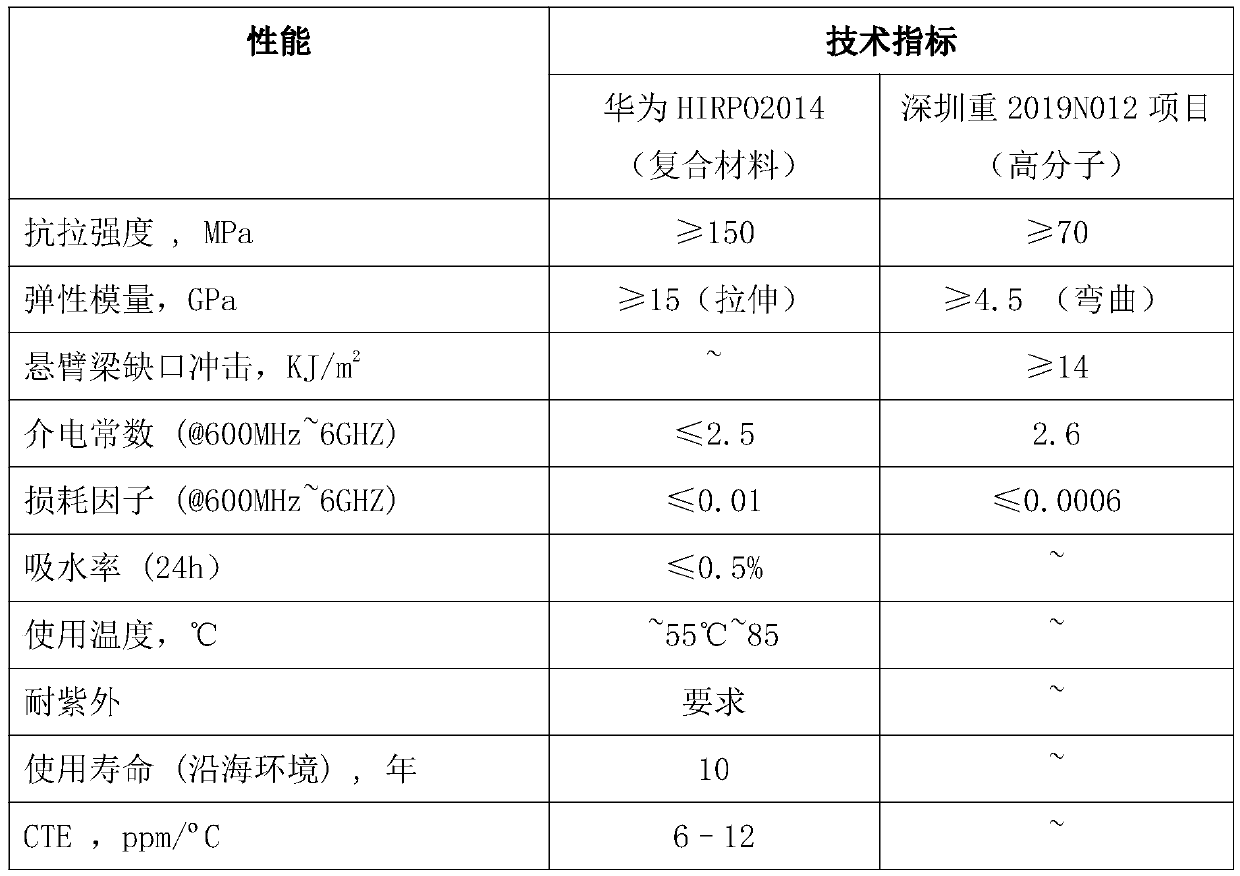

[0047] The radome made of the radome material provided by the present invention has a bulletproof function, and the above-mentioned radome adopts a single-layer or multi-layer structure of ultra-high molecular weight polyethylene fiber braided preform and modified polyethylene film thermocompression forming, dielectric The constant is less than 2.6, the loss factor is below 0.005, the tensile strength is greater than 100MPa, and the tensile modulus is greater than 10GPa. The thickness of the wave-transmitting surface of the above-mentioned radome is less than 3mm, and the thickness of the more common radome is less than 2mm. Even a radome with a thickness of 0.5mm can withstand the stress of outdoor applications. Adopting the radome material provided by the present invention to make the wave-transmitting performance of the radome and 2mm thick, the wave-transmitting performance of the radome made by the polycarbonate of 2.9 and the 2mm thick, the dielectric constant being the p...

Embodiment 2

[0057] On the basis of Example 1, this example illustrates the synthesis method of a specific high-hardness silicone resin.

[0058] In a three-necked flask, add 5mol of trimethoxyphenylsilane, 0.25mol of dimethoxyphenylmethylsilane, 0.12mol of tetraethoxysilane, and 0.2mol of phenyl cage silsesquioxane, and 2 liters of methyl isobutyl ketone (MIBK), turn on the mechanical stirrer, dropwise add 360 g of 0.5 mol hydrochloric acid aqueous solution, control the temperature below 40 ° C, then carry out hydrolysis condensation under the conditions of rapid stirring and heating to reflux, and hydrolyze 2 After 1 hour, the temperature was raised to 60°C, and the reaction was continued for 5 hours. The reaction solution was poured into a separatory funnel, allowed to stand for stratification, and the water layer was separated. The oil layer was washed with water until neutral, and 1M potassium hydroxide was added to the reaction solution. Methanol solution, the quality of the above 1M...

Embodiment 3

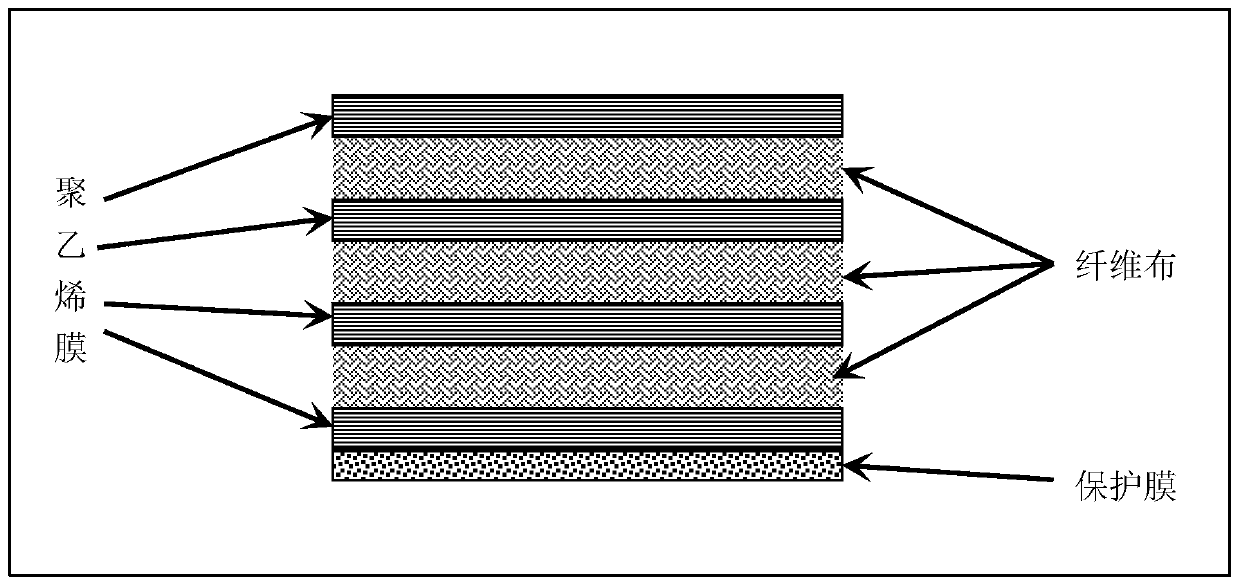

[0061] Using 0.25mm thick plain weave ultra-high molecular weight polyethylene fiber cloth, its surface density is about 120g / m 2 , the ultra-high molecular weight polyethylene fiber cloth is treated with the same 5% high-hardness silicone resin solution in Example 2, and the processing method is to immerse the fiber cloth in the solution for 2 to 5 minutes, take it out, and place it at a temperature of 80° C. Dry in the oven. The ultra-high molecular weight polyethylene fiber cloth after the high-hardness silicone resin has been shaped can be accurately cut into the desired shape, and the required 0.12mm thick polyethylene film is cut into the same shape as the ultra-high molecular weight polyethylene fiber cloth, and arranged in sequence number overlap, see figure 2 , the structure from bottom to top is: the bottom layer is 0.03mm polycarbonate protective film, the first layer of polyethylene film, then alternately arrange fiber cloth and polyethylene film, and the top lay...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com