A kind of preparation method of graphene and liquid crystal polyester synergistically reinforced polymer fiber

A technology of liquid crystal polyester and graphene, applied in the direction of conjugated synthetic polymer rayon, fiber processing, fiber chemical characteristics, etc., can solve the problems of poor spinnability, complicated preparation process, high product price, etc. The effect of improving tensile strength at break, crystallinity and crystal regularity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

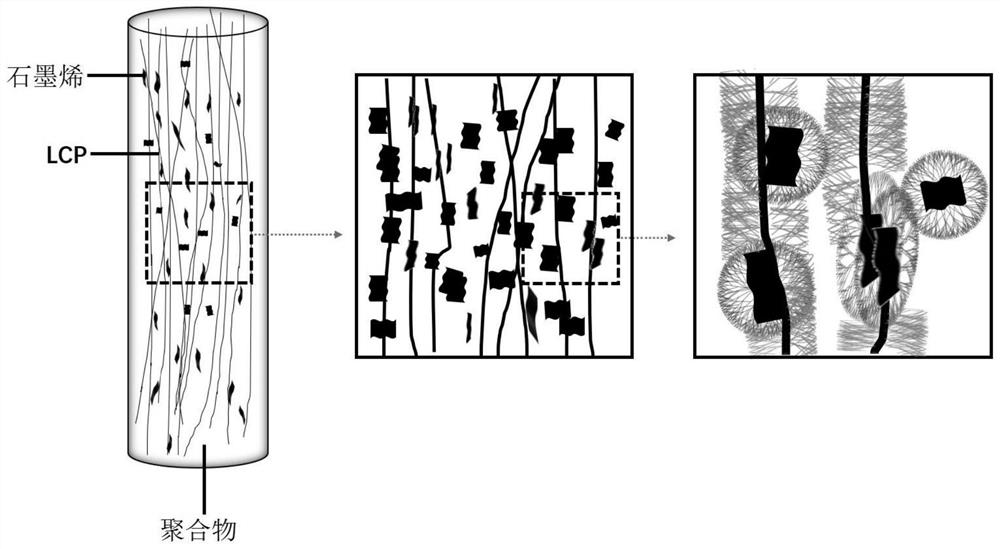

[0023] The invention provides a preparation method (method for short) of a synergistic reinforced polymer fiber of graphene and liquid crystal polyester, which is characterized in that the method comprises the following steps:

[0024] (1) The graphene and liquid crystal polyester pellets are mixed uniformly in a high-speed mixer as component A; the polymer is used as component B; wherein the mass ratio of graphene to liquid crystal polyester is 0.05~2:98.0~99.95;

[0025] Preferably, the mixed material of graphene and liquid crystal polyester is melt-extruded and granulated in an extruder, and dried as component A;

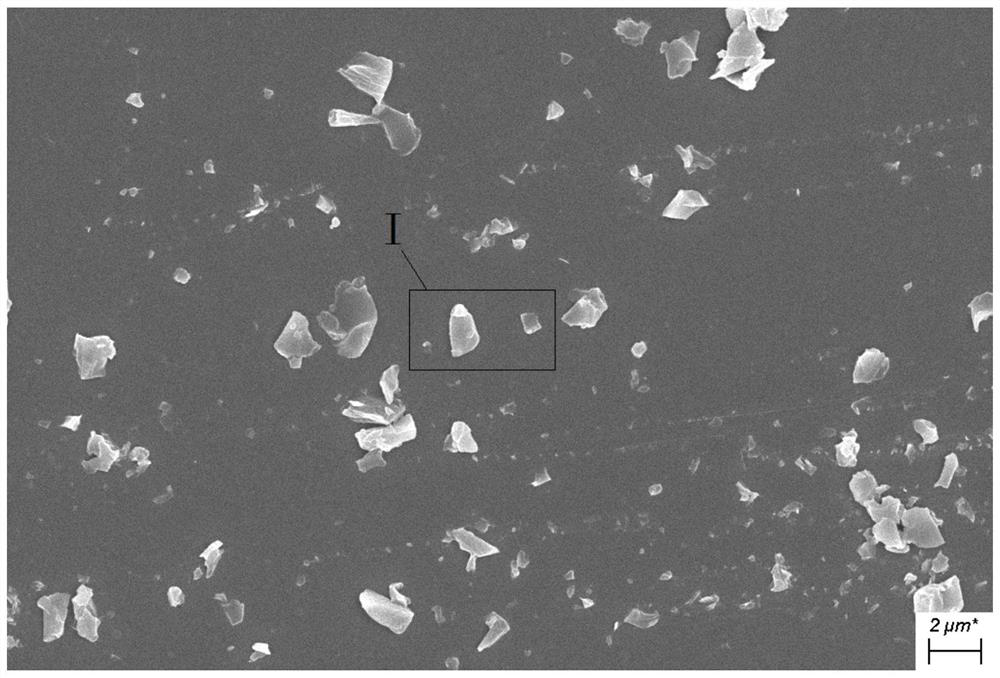

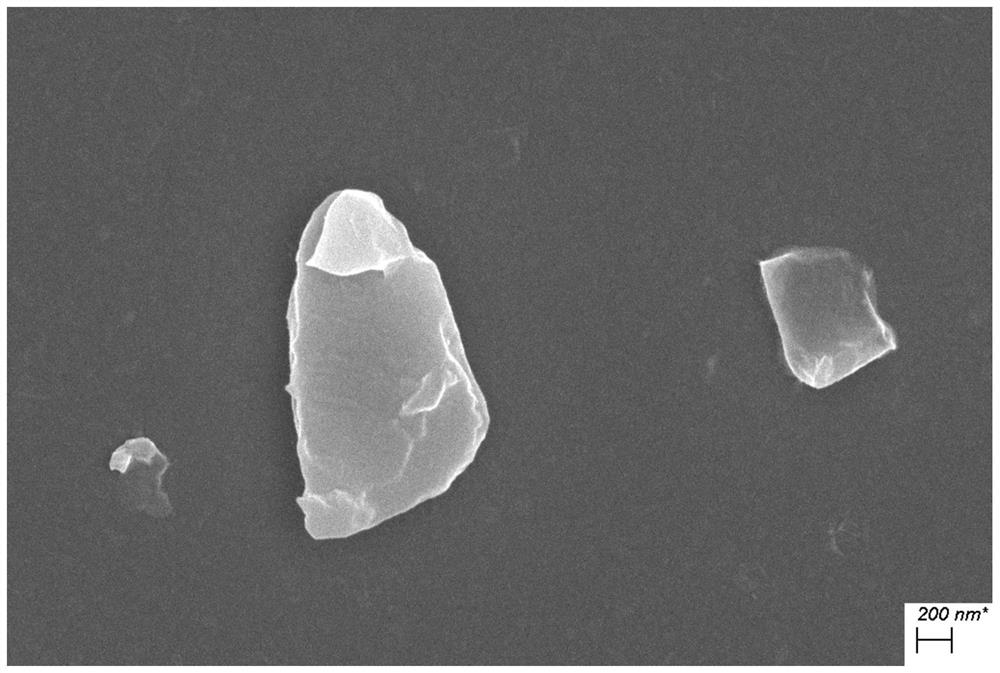

[0026] The graphene refers to graphene whose radial dimension is submicron or nanometer (0.1-0.9 μm), single-layer or few-layer (1-3 layers), and whose moisture content is lower than 120 ppm, including reduced graphene oxide and graphite oxide. graphene (GO) or functionalized graphene; the use of submicron or nanometer radial size graphene is beneficial to achiev...

Embodiment 1

[0039] Poly(2-hydroxy-6-naphthoic acid-p-hydroxybenzoic acid) copolymer (2-hydroxy- The molar ratio of 6-naphthoic acid and p-hydroxybenzoic acid was 73:27) and 98 parts by mass were mixed uniformly as component A.

[0040] Take 10 parts by mass of component A, and add 90 parts by mass of PET (component B) with an intrinsic viscosity of 1.2 to a single-screw extruder with a diameter of 25 mm. , 300 ℃, pump seat temperature 300 ℃, spinneret diameter 0.25mm.

[0041] After the thread was cooled in an air tunnel at 60°C, 65% relative humidity, and 0.4m / s wind speed, the speed of the first godet roll was 1500m / min, the first draft roll was 150°C, the second draft roll was 160°C, The drafting roller is 230°C, and the draft is 4.0 times. After setting by a 160°C hot roller, the composite fiber is wound at a speed of 5950 m / min.

[0042] The tensile breaking strength of the composite fiber was measured to be 10.2 cN / dtex, which was significantly higher than that of the PET industri...

Embodiment 2

[0045] 0.05 parts by mass of 1-3 layers of graphene with an average radial size of 0.1 microns, an intrinsic viscosity of 2.0 dL / g bisphenol A and isophthalic acid / terephthalic acid random copolymer (bisphenol A and m-terephthalic acid) The molar ratio of phthalic acid / terephthalic acid was 50:50) and 99.5 parts by mass was mixed uniformly as the A component.

[0046] Take 20 parts by mass of component A, and add it together with 80 parts by mass of PA66 with a relative viscosity of 3.1 into a single screw extruder with a diameter of 25 mm for melt extrusion and spinning. Other process and process parameters are the same as in Example 1.

[0047] The tensile breaking strength of the composite fiber was measured to be 9.5cN / dtex, which was significantly higher than that of the PA66 industrial yarn, and the crystallinity of the fiber reached 61%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com