Low-smoke halogen-free flame-retardant cable material

A flame-retardant cable material and raw material technology, applied in the field of cable materials, can solve the problems of reduced mechanical properties and processing properties of materials, influence of mechanical properties of polymer materials, poor flame-retardant efficiency of magnesium hydroxide, etc., to reduce surface energy and accelerate The rate of thermal decomposition and the effect of improving the modification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

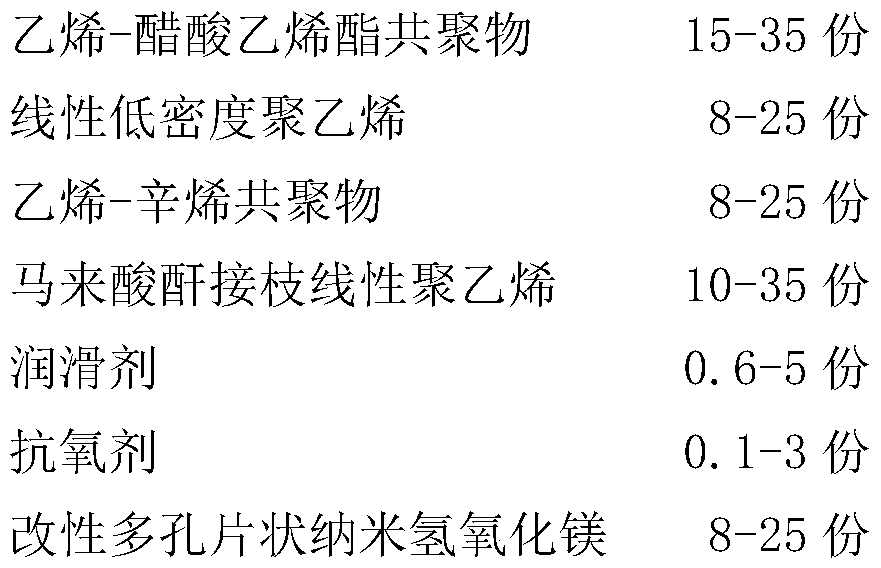

[0022] A low-smoke halogen-free flame-retardant cable material, the raw materials of which include the following components in parts by weight: 15 parts of ethylene-vinyl acetate copolymer, 8 parts of linear low-density polyethylene, 8 parts of ethylene-octene copolymer, 10 parts of acid anhydride grafted linear polyethylene, 0.6 part of stearic acid, 0.1 part of antioxidant 1010, and 8 parts of modified porous sheet-like nano-magnesium hydroxide.

[0023] Wherein, the modified porous flaky nano-magnesium hydroxide is a porous flaky nano-magnesium hydroxide modified by nano polyacrylate microemulsion, and its preparation method comprises the following steps:

[0024] a) Weigh 13.3g of magnesium chloride, add 210mL of deionized water to prepare magnesium chloride solution, slowly add 140mL of ammonia water with a concentration of 25%, add 7g of sodium lauryl sulfate after the dropwise addition, mix well and pour In the autoclave, carry out hydrothermal reaction, the reaction te...

Embodiment 2

[0029] A low-smoke halogen-free flame-retardant cable material, the raw materials of which include the following components by weight: 35 parts of ethylene-vinyl acetate copolymer, 25 parts of linear low-density polyethylene, 25 parts of ethylene-octene copolymer, 35 parts of acid anhydride grafted linear polyethylene, 5 parts of magnesium stearate, 3 parts of antioxidant 168, 25 parts of modified porous sheet-like nano-magnesium hydroxide.

[0030] Wherein, the modified porous flaky nano-magnesium hydroxide is a porous flaky nano-magnesium hydroxide modified by nano polyacrylate microemulsion, and its preparation method comprises the following steps:

[0031] a) Weigh 47.5g of magnesium chloride, add 750mL of deionized water to prepare a magnesium chloride solution, slowly add 500mL of ammonia water with a concentration of 28%, add 25g of sodium lauryl sulfate after the addition, mix well and pour In the autoclave, carry out hydrothermal reaction, the reaction temperature is ...

Embodiment 3

[0036] A low-smoke halogen-free flame-retardant cable material, the raw materials of which include the following components in parts by weight: 25 parts of ethylene-vinyl acetate copolymer, 16 parts of linear low-density polyethylene, 16 parts of ethylene-octene copolymer, 20 parts of acid anhydride grafted linear polyethylene, 2.5 parts of polyethylene wax, 1.5 parts of antioxidant DLTP, and 16 parts of modified porous sheet-shaped nano-magnesium hydroxide.

[0037] Wherein, the modified porous flaky nano-magnesium hydroxide is a porous flaky nano-magnesium hydroxide modified by nano polyacrylate microemulsion, and its preparation method comprises the following steps:

[0038] a) Weigh 28.5g of magnesium chloride, add 450mL of deionized water to prepare magnesium chloride solution, slowly add 300mL of ammonia water with a concentration of 26%, add 15g of sodium lauryl sulfate after the addition, mix well and pour In the autoclave, carry out hydrothermal reaction, the reaction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com