Preparation method of high-performance neodymium-iron-boron magnet

A NdFeB, high-performance technology, applied in the direction of magnetic objects, inductor/transformer/magnet manufacturing, magnetic materials, etc., can solve the problems of inability to increase the unit weight of the surface of the magnet, limited coercive force increase, and insufficient diffusion depth, etc. , to achieve the effect of improving material utilization, eliminating the influence of surface tension, and high diffusion uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

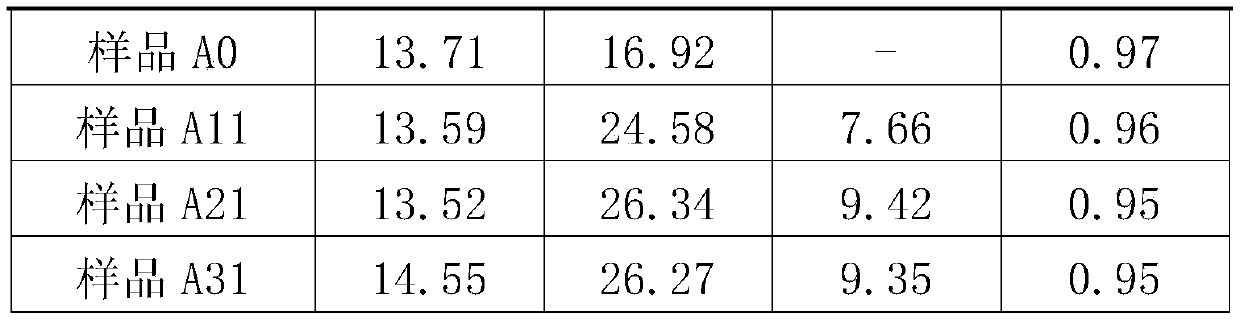

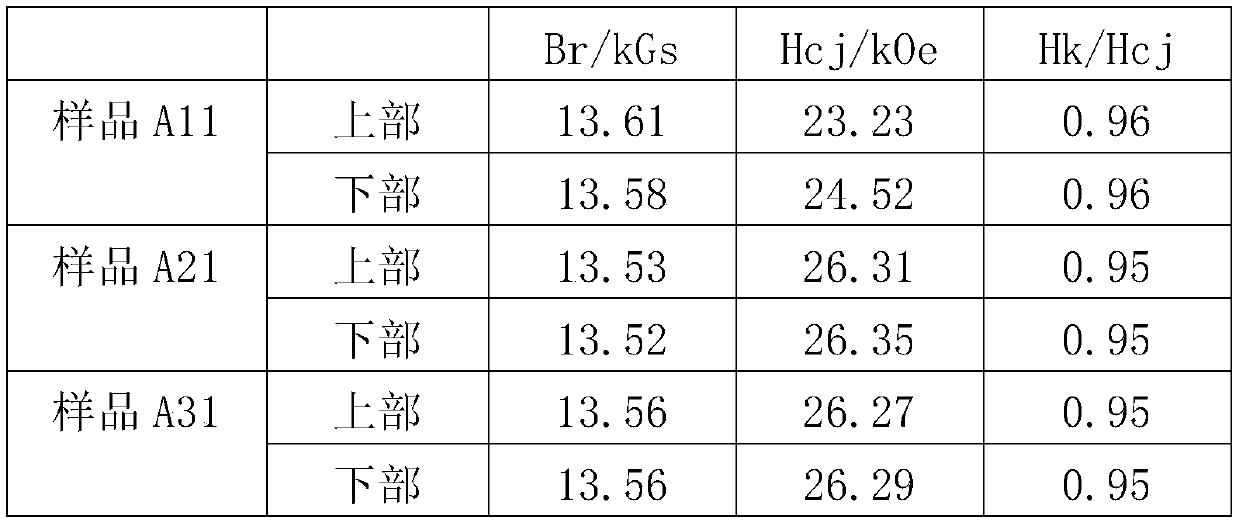

Embodiment 1

[0024] A method for preparing a high-performance NdFeB magnet, comprising the following steps:

[0025] A. The weight ratio of neodymium, dysprosium, terbium, cobalt, copper, aluminum and boron: Nd-21.8%, Pr-7.4%, Dy-1.5%, Co-1.0%, Cu-0.10%, Al-0.10%, The proportion of Ga-0.10%, Zr-0.10%, B-0.96%, the balance is Fe and unavoidable impurities, the pouring is completed in a vacuum melting furnace under an inert gas environment, the pouring temperature is 1450°C, and the speed of the quenching roll is 60r / min, cooling water is passed through the quenching roller, and the thickness of the obtained scales is about 0.36mm; then, the scales are subjected to hydrogen absorption and dehydrogenation crushing in a hydrogen crushing furnace, and then passed through a jet mill to make magnetic powder with an average particle size of 3.4 μm; at room temperature Orientation pressing is carried out in an environment with a magnetic field strength of 2T orientation field to make a compact; pu...

Embodiment 2

[0043]1), neodymium, dysprosium, terbium, cobalt, copper, aluminum, boron by weight: Nd-22.9%, Pr-7.6%, Co-0.5%, Cu-0.35%, Al-0.40%, Ga-0.40% , Zr-0.15%, B-0.96%, the balance is Fe and unavoidable impurities, pouring is completed in a vacuum melting furnace under an inert gas environment, the pouring temperature is 1450 ° C, the speed of the quenching roll is 60r / min, and the quenching Cooling water is passed through the roller, and the obtained scales have a thickness of about 0.32 mm; then, the scales are crushed by hydrogen absorption and dehydrogenation in a hydrogen crushing furnace, and then passed through a jet mill to make magnetic powder with an average particle size of 3.2 μm; at room temperature and magnetic field strength of Orientation pressing was carried out in an orientation field environment of 2T to make a compact; the compact was placed in a sintering furnace under an Ar atmosphere, and sintered at 1075°C for 5h to obtain a green compact, which was aged at 50...

Embodiment 3

[0054] 1), neodymium, dysprosium, terbium, cobalt, copper, aluminum, boron by weight: Nd-22.9%, Pr-7.6%, Co-0.5%, Cu-0.35%, Al-0.40%, Ga-0.40% , Zr-0.15%, B-0.96%, the balance is Fe and unavoidable impurities, pouring is completed in a vacuum melting furnace under an inert gas environment, the pouring temperature is 1450 ° C, the speed of the quenching roll is 60r / min, and the quenching Cooling water is passed through the roller, and the obtained scales have a thickness of about 0.32 mm; then, the scales are crushed by hydrogen absorption and dehydrogenation in a hydrogen crushing furnace, and then passed through a jet mill to make magnetic powder with an average particle size of 3.2 μm; at room temperature and magnetic field strength of Orientation pressing was carried out in an orientation field environment of 2T to make a compact; the compact was placed in a sintering furnace under an Ar atmosphere, and sintered at 1075°C for 5h to obtain a green compact, which was aged at 5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com