Catalyst for preparing meta-xylylenediamine and application of catalyst

The technology of m-xylylenediamine and catalyst is applied in the field of synthesis of m-xylylenediamine and hydrogenation catalyst, which can solve the problems of complex separation, low activity and selectivity, and high composition, so as to optimize reaction process conditions and reduce Side reactions, the effect of improving selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

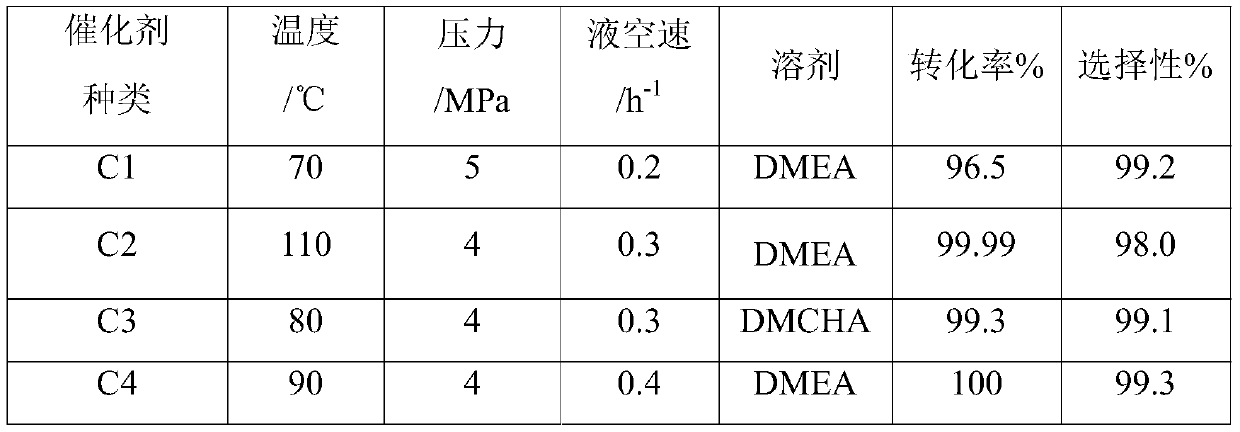

Examples

Embodiment 1

[0022] Weigh 1000g of aluminum nitrate nonahydrate and deionized water to prepare 1L solution, pour it into a 3L glass reaction kettle with stirring and heating and raise the temperature to 60°C, add 18% ammonia solution dropwise, and carry out neutralization and precipitation. The neutralization time is 15 Minutes, adjust the final pH value to 7.6, age for 40 minutes, fix the crystal form, and obtain a filter cake after filtration; the filter cake is dried, pulverized and added with 5.2 g of forming aids magnesium stearate and 1.4 g of pore-forming aids carboxymethyl cellulose g, pressed into The tablets were then calcined at a temperature of 800° C. for 2 hours to obtain the carrier Z1. The physical and chemical data of the carrier are shown in Table 1.

Embodiment 2

[0024] Weigh 800g of aluminum nitrate and 200g of magnesium nitrate hexahydrate plus deionized water to prepare 1L of solution, pour it into a 3L glass reactor with stirring and heating and raise the temperature to 80°C, add 15% ammonia solution dropwise for neutralization and precipitation. The mixing time is 25 minutes, adjust the end point pH value to 7.2, age for 20 minutes, fix the crystal form, and obtain a filter cake after filtration; the filter cake is dried, pulverized and added with 1.9 g of forming aids magnesium stearate and pore-forming aids Sinensis Powder 3.0g, pressed into The tablets were then calcined at a temperature of 700° C. for 4 hours to obtain the carrier Z2. The physical and chemical data of the carrier are shown in Table 1.

Embodiment 3

[0026] Weigh 700g of aluminum nitrate and 350g of magnesium acetate tetrahydrate plus deionized water to prepare 1L of solution, pour it into a 3L glass reaction kettle with stirring and heating and raise the temperature to 70°C, add 10% ammonia solution dropwise for neutralization and precipitation. The mixing time is 35 minutes, adjust the end point pH value to 7.8, age for 30 minutes, fix the crystal form, and obtain a filter cake after filtration; the filter cake is dried, pulverized and added with 2.0 g of forming aid stearic acid, pore-forming aid carboxymethyl Cellulose 3.0g, pressed into The tablets were then calcined at a temperature of 900° C. for 2 hours to obtain the carrier Z3. The physical and chemical data of the carrier are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com