An integrated method for forming and controlling nial alloy thin-walled pipe fittings

An alloy, thin-walled technology, applied in the field of precision forming of intermetallic compound thin-walled pipe fittings, can solve the problems of voids, material fractures, and complicated welding process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

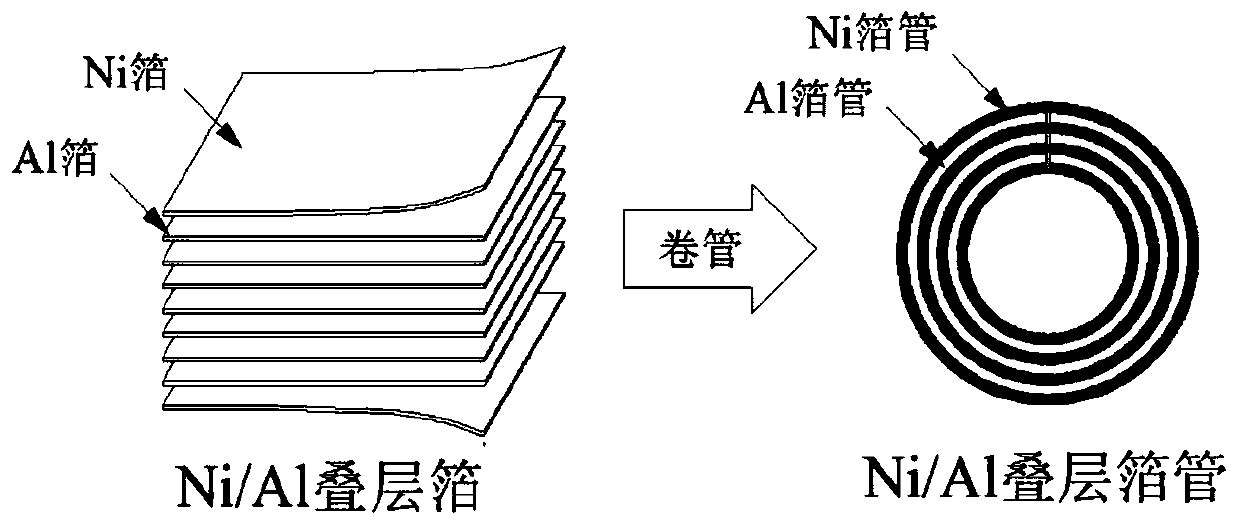

[0065] An integrated method for forming and controlling NiAl alloy thin-walled pipe fittings, comprising the following steps:

[0066] (1) According to the atomic number ratio of Ni atoms and Al atoms in NiAl alloy, calculate the thickness ratio of Ni foil and Al foil; polish Ni foil and Al foil with fine sandpaper, and then put it into acetone solution for ultrasonic Wash, then soak in distilled water for 1 min, take it out and dry it with cold air to obtain pretreated Ni foil and pretreated Al foil; the specific calculation process of the thickness ratio of Ni foil and Al foil is:

[0067] N=n×N A (1); Wherein, N represents number of atoms, and n represents the amount of substance, N A represents Avogadro's number;

[0068] m=n * M (II), wherein, m represents quality, and n represents the amount of substance, and M represents the molar mass of substance;

[0069] h=m / (ρ S) (III), wherein, h represents height, m represents quality, ρ represents density, and S represents ...

Embodiment 2

[0076] An integrated method for forming and controlling NiAl alloy thin-walled pipe fittings, comprising the following steps:

[0077] (1) same as embodiment 1;

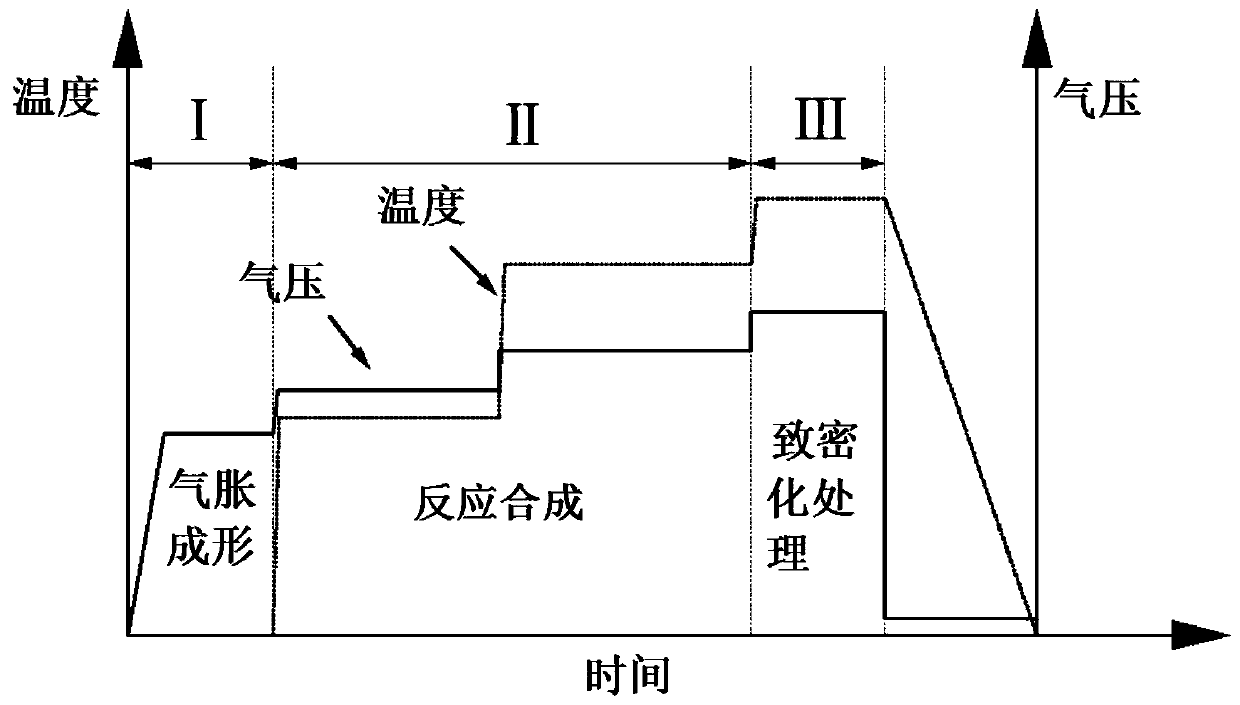

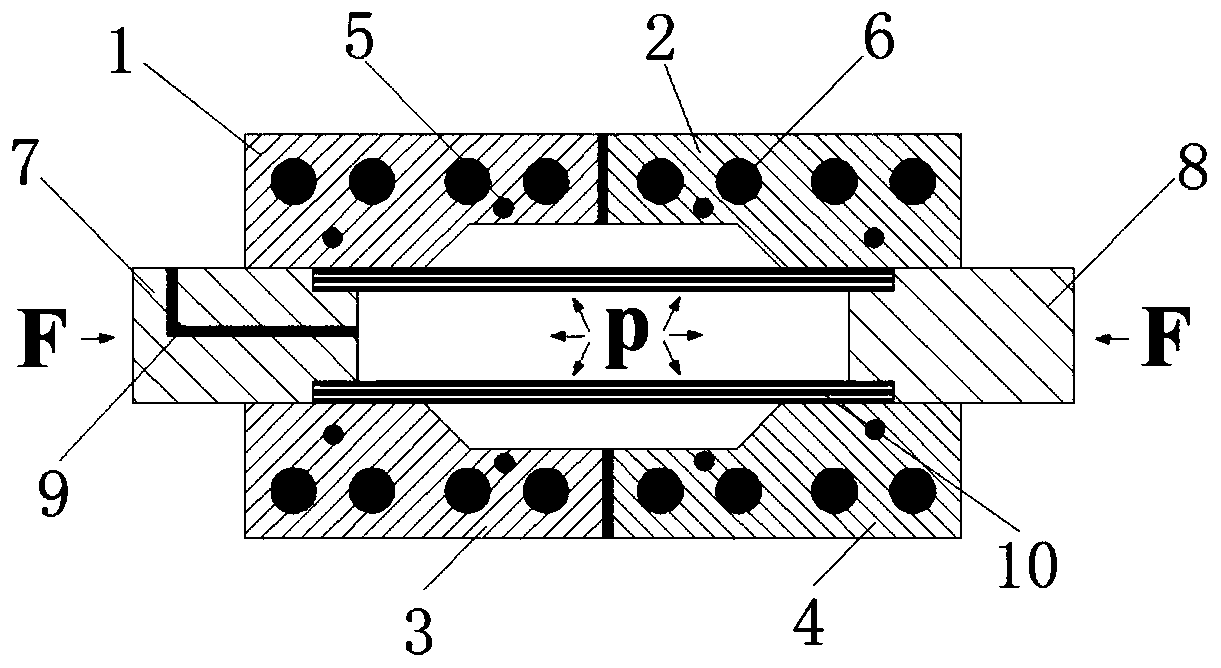

[0078] (2) Alternately stack several pretreated Ni foils and several pretreated Al foils to obtain a Ni / Al laminated foil; Insert the metal shaft tube inside, and apply boron nitride solder resist between the Ni / Al laminated foil tube and the metal shaft tube, and put the Ni / Al laminated foil tube and the metal shaft tube into the cylindrical cavity mold as a whole The temperature of the expansion is 400°C, the gas pressure of the expansion is 20MPa, and the time of the expansion is 0.5h; then the Ni / Al laminated foil tube and the metal shaft tube are taken out as a whole, and the internal Take out the metal shaft tube;

[0079] (3) The Ni / Al laminated foil tube is placed in the inflation forming mold, and the inflation forming mold is heated to 400° C. for inflation forming. The pressure required for the inflation...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com