High-chromium cast iron for wear-resisting grinding ball and preparation method of high-chromium cast iron

A high-chromium cast iron and wear-resistant ball technology, applied in the field of wear-resistant balls, can solve the problems of high impact toughness of cast iron balls, increase production costs, and reduce production efficiency, and achieve high impact loads, improve hardness and wear resistance, The effect of improving hardenability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

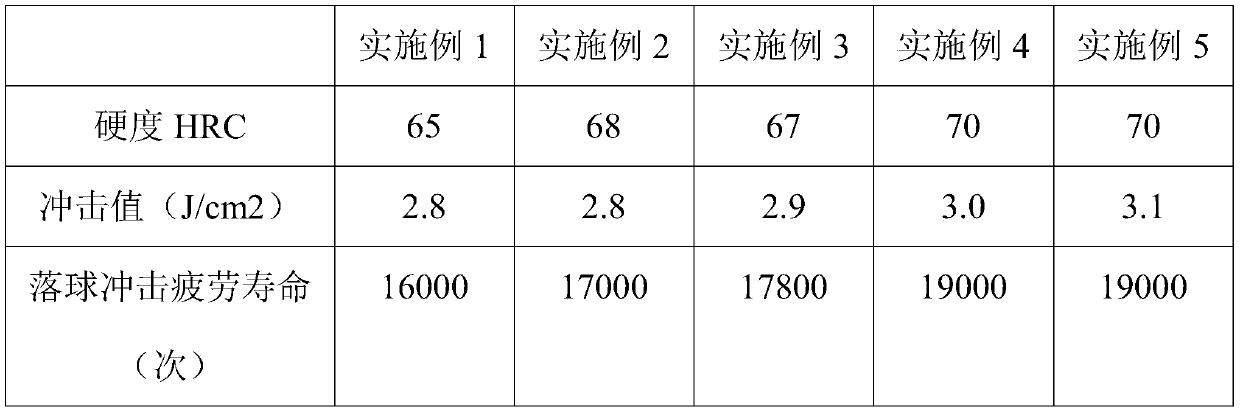

Examples

Embodiment 1

[0021] A high chromium cast iron used for wear-resistant balls proposed by the present invention is composed of the following components by weight percentage: C2.3%, Si 1.0%, Mn 0.4%, Cr 16%, Mo 0.6%, Ni 0.4 %, V 0.08%, B 0.1%, Nb 0.1%, Re 0.1%, S 0.03%, P 0.03%, and the balance is Fe.

[0022] The present invention also proposes a method for preparing the above-mentioned high-chromium cast iron for wear-resistant balls, comprising the following steps:

[0023] S1. Smelting: Add steel scrap, pig iron, ferrosilicon, and ferromanganese into an intermediate frequency induction furnace for smelting, adjust the composition before the furnace, raise the temperature to 1550°C, and then perform deoxidation treatment, and then add ferrochrome, ferromolybdenum, ferrovanadium, and nickel block, ferro-niobium, then add ferro-boron for the first modification treatment, then add Re for the second modification treatment, and then release from the furnace;

[0024] S2. Casting: pouring the m...

Embodiment 2

[0027] A high-chromium cast iron used for wear-resistant balls proposed by the present invention is composed of the following components by weight percentage: C3.0%, Si 0.5%, Mn 1.0%, Cr 20%, Mo 0.3%, Ni 0.8 %, V 0.02%, B 0.05%, Nb 0.2%, Re 0.01%, S 0.03%, P 0.03%, and the balance is Fe.

[0028] The present invention also proposes a method for preparing the above-mentioned high-chromium cast iron for wear-resistant balls, comprising the following steps:

[0029] S1. Smelting: Add steel scrap, pig iron, ferrosilicon, and ferromanganese into an intermediate frequency induction furnace for smelting, adjust the composition before the furnace, raise the temperature to 1570°C, and then perform deoxidation treatment, and then add ferrochromium, ferromolybdenum, ferrovanadium, and nickel block, ferro-niobium, then add ferro-boron for the first modification treatment, then add Re for the second modification treatment, and then release from the furnace;

[0030] S2. Casting: pouring t...

Embodiment 3

[0033] A high chromium cast iron used for wear-resistant balls proposed by the present invention is composed of the following components by weight percentage: C2.5%, Si 0.9%, Mn 0.5%, Cr 17%, Mo 0.5%, Ni 0.6 %, V 0.05%, B 0.08%, Nb 0.16%, Re 0.04%, S 0.02%, P 0.02%, and the balance is Fe.

[0034] The present invention also proposes a method for preparing the above-mentioned high-chromium cast iron for wear-resistant balls, comprising the following steps:

[0035] S1. Smelting: Add steel scrap, pig iron, ferrosilicon, and ferromanganese into an intermediate frequency induction furnace for smelting, adjust the composition before the furnace, raise the temperature to 1560°C, and then perform deoxidation treatment, and then add ferrochromium, ferromolybdenum, ferrovanadium, and nickel block, ferro-niobium, then add ferro-boron for the first modification treatment, then add Re for the second modification treatment, and then release from the furnace;

[0036] S2. Casting: pouring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com