A kind of thermoplastic polyester elastomer and foam

A thermoplastic polyester and elastomer technology, applied in the field of thermoplastic elastomer foaming, can solve the problems of large pores, open pores or uneven pore diameters, achieve a balance between tensile strength and low melting point, facilitate foaming processing, and improve melt The effect of intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0058] Another embodiment of the present invention provides the preparation method of the thermoplastic polyester elastomer as described above, comprising the following steps:

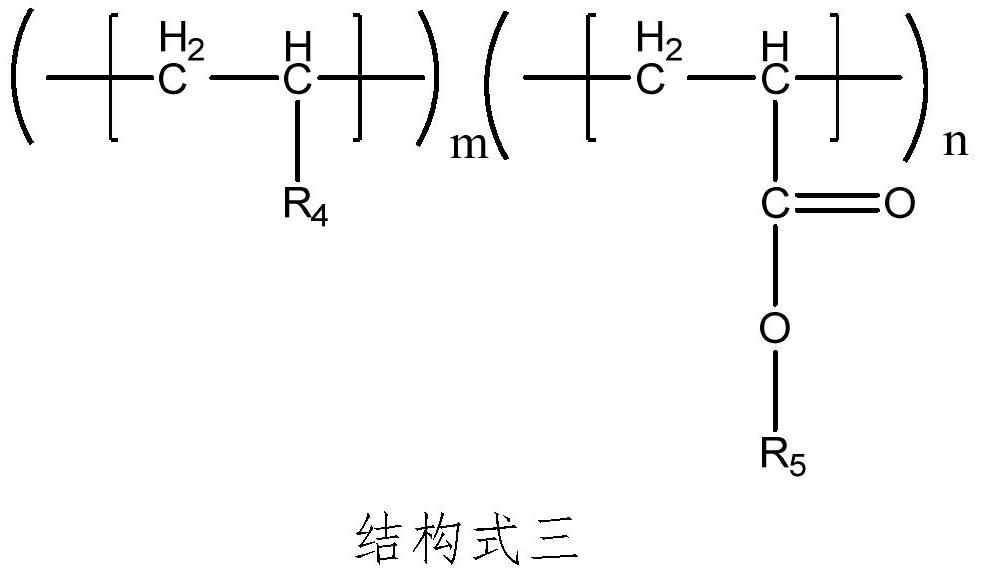

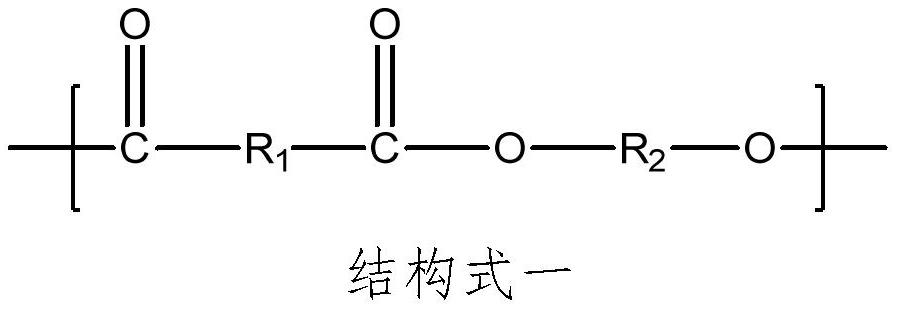

[0059] A reaction mixture is obtained by mixing dicarboxylic acid or dimethyl ester of aromatic group or tetrahydrofuran group, polyalcohol with 3 to 6 carbons, soft segment monomer and prepolymer monomer, and the prepolymer monomer is composed of It is obtained by polymerization of aromatic monomers with vinyl groups and acrylate monomers;

[0060] The reaction mixture first undergoes esterification reaction or transesterification reaction, and then undergoes polycondensation reaction to obtain thermoplastic polyester elastomer.

[0061] The preparation method of thermoplastic polyester elastomer provided by the present invention uses the prepolymer monomer obtained by polymerization of aromatic monomers with vinyl groups and acrylate monomers as one of the raw materials, and two Carboxylic acid or d...

Embodiment 1

[0094] This embodiment is used to illustrate the thermoplastic polyester elastomer, thermoplastic polyester elastomer foam and preparation method thereof disclosed in the present invention, including the following steps:

[0095] Add 17.5KG of butyl acetate into a 100L reactor, raise the temperature to 120°C, and drop a mixed solution of 1.125KG tert-butyl peroxybenzoate, 16.7KG styrene and 0.8KG methyl methacrylate from a metering pump, 2.5 The hour dropwise addition was completed. After the dropwise addition was completed, the reaction was continued at 120° C. for 4 hours. A PA intermediate of random copolymerization of styrene-methyl methacrylate was obtained. The solid content was 50.1%, the viscosity was 1150 cps, and the number average molecular weight was 2160.

[0096] Add 7.33KG of butylene glycol, 12.1KG of dimethyl terephthalate, 10.5KG of polytetrahydrofuran diol, 2.7KG of PA intermediate, and 12.5g of tetrabutyl titanate as a catalyst in a 100L reactor , antioxi...

Embodiment 2

[0099] This embodiment is used to illustrate the thermoplastic polyester elastomer, thermoplastic polyester elastomer foam and preparation method thereof disclosed in the present invention, including most of the operating steps in Example 1, the difference being:

[0100] The amount of PA intermediate was changed from 2.7KG to 5.4KG.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com