Magnesium oxysulfate pasting wood rock porcelain non-combustible board and manufacturing method thereof

A technology for sticking wood and veneer with magnesium oxysulfide, applied in the field of building decorative panels, can solve the problems of easy moisture absorption and halogen return, high corrosion of chloride ion metal, heavy weight of cement fiber board and gypsum board, etc., and achieves good flame retardancy and fire resistance. , Conducive to the seismic effect of the structure and the light weight structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Embodiments of the technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solutions of the present invention more clearly, and therefore are only examples, rather than limiting the protection scope of the present invention. It should be noted that, unless otherwise specified, the technical terms or scientific terms used in this application shall have the usual meanings understood by those skilled in the art to which the present invention belongs.

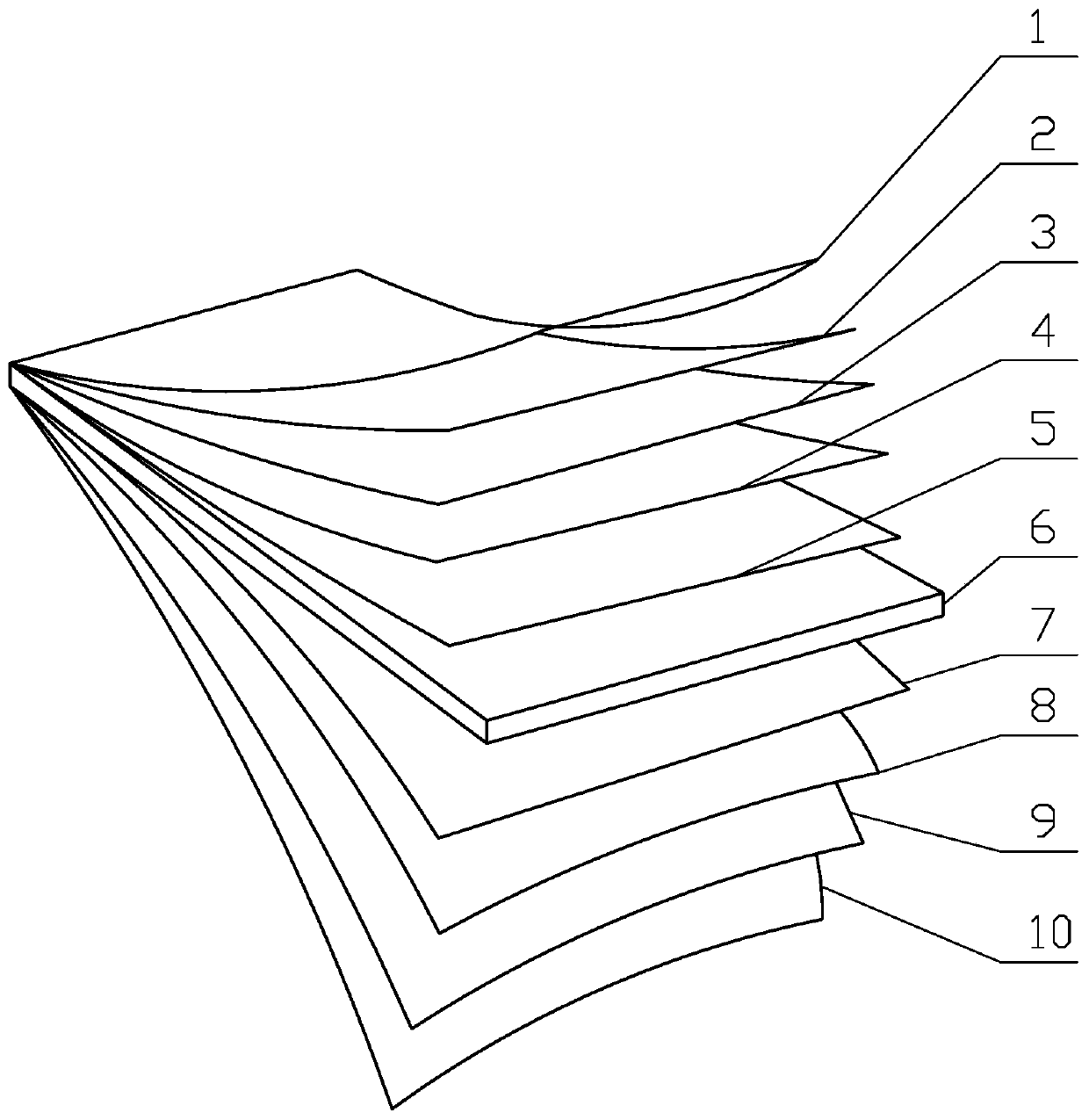

[0036] Such as figure 1 Shown: in the middle of the plate of the present invention is the magnesium oxysulfate base material 6 that is provided with multi-layer glass fiber cloth, and the upper surface of the magnesium oxysulfide base material 6 is provided with balance cloth 5, veneer 4, water-based UV color essence bottom in sequence from bottom to top Paint 3, water-based UV primer 2 and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com