Low-pressure preparation method for silicon carbide thin film epitaxy

A silicon carbide and silicon carbide substrate technology, applied in chemical instruments and methods, gaseous chemical plating, from chemically reactive gases, etc., can solve the problems of epitaxial surface morphology degradation, material quality reduction, etc., to reduce surface defects Density, avoidance of deposits, effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

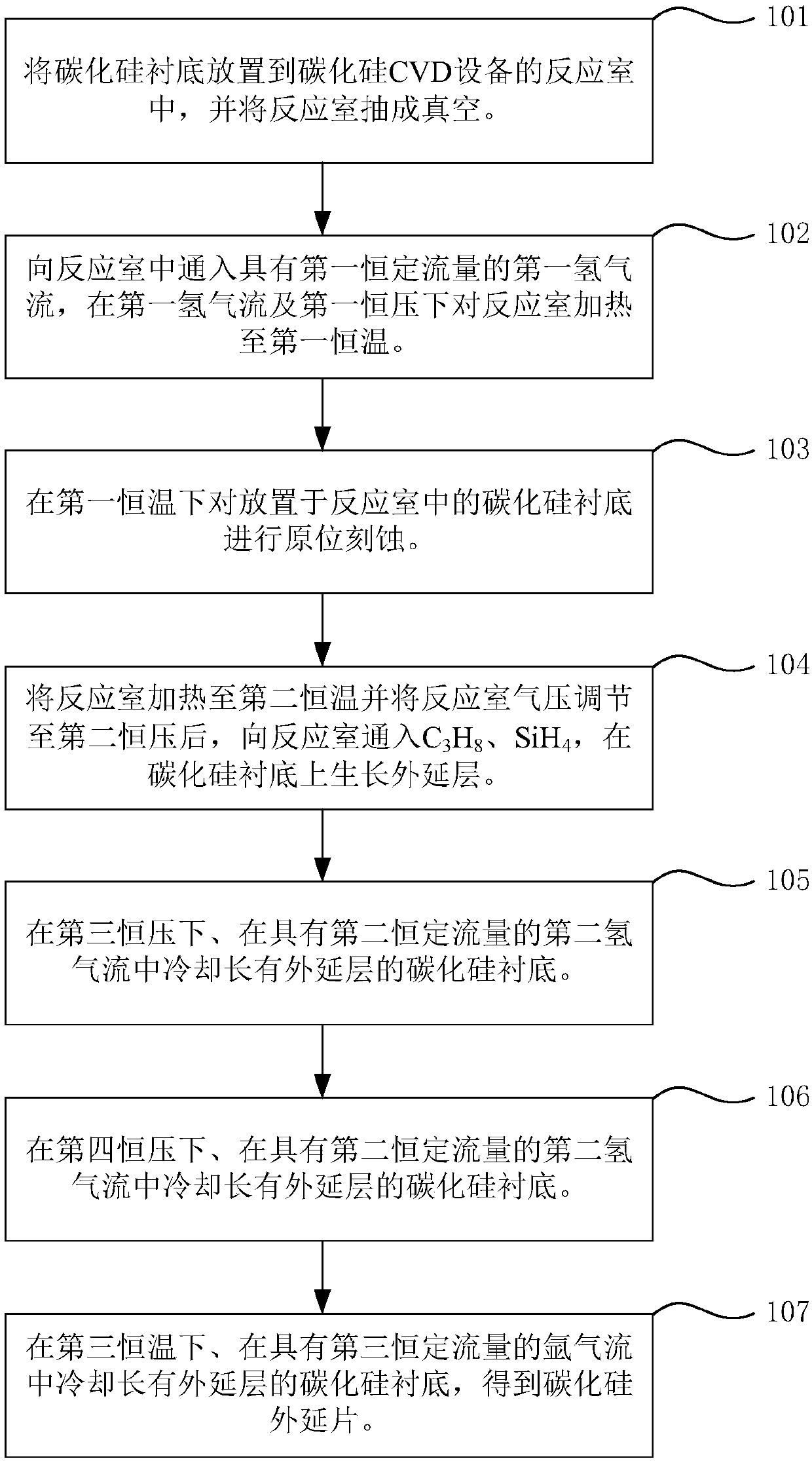

[0025] see figure 1 , figure 1 A schematic structural diagram of a virtual LED display module based on a three-color I-shaped LED chip provided by an embodiment of the present invention.

[0026] 101. Put the silicon carbide substrate into the reaction chamber of the silicon carbide CVD equipment, and evacuate the reaction chamber. CVD stands for Chemical Vapor Deposition. This step specifically includes:

[0027] 101a. Selecting a silicon carbide substrate;

[0028] In one embodiment of the present invention, a 4H silicon carbide substrate with a 4° orientation to [1120] is selected;

[0029] In another embodiment of the present invention, a 4H silicon carbide substrate with an orientation of 8° to [1120] is selected;

[0030] 101b. Evacuate the reaction chamber, specifically to make the pressure of the reaction chamber lower than 1×10 -7 mbar.

[0031] 102. Introduce a first hydrogen flow with a first constant flow rate into the reaction chamber, and heat the reaction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com