Silicon nitride sintered body and preparation method thereof

A technology of silicon nitride and sintered body, which is applied in the field of materials, can solve the problems of low temperature, inability to retain the metal state, and the inability to retain the metal state, etc., and achieve the effect of good bending strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Put 3g of metal tungsten powder with a diameter of 1 μm, 3g of alumina powder, 9g of yttrium oxide powder, and 85g of silicon nitride powder into a silicon nitride ball mill jar, add 150g of absolute ethanol, and 200g of silicon nitride grinding balls;

[0047] Planetary ball mill ball milling for 4 hours, drying in an oven at 80°C for 4 hours, and sieving with 60 mesh to obtain powder raw materials;

[0048] The powder is formed by 10MPa dry pressing and 200MPa cold isostatic pressing;

[0049] The samples were sintered at 1750°C for 2h under 5MPa nitrogen pressure.

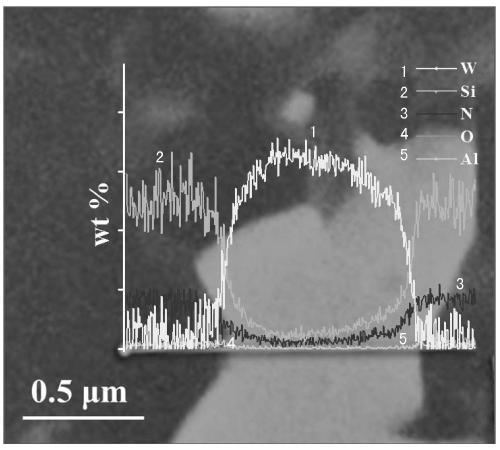

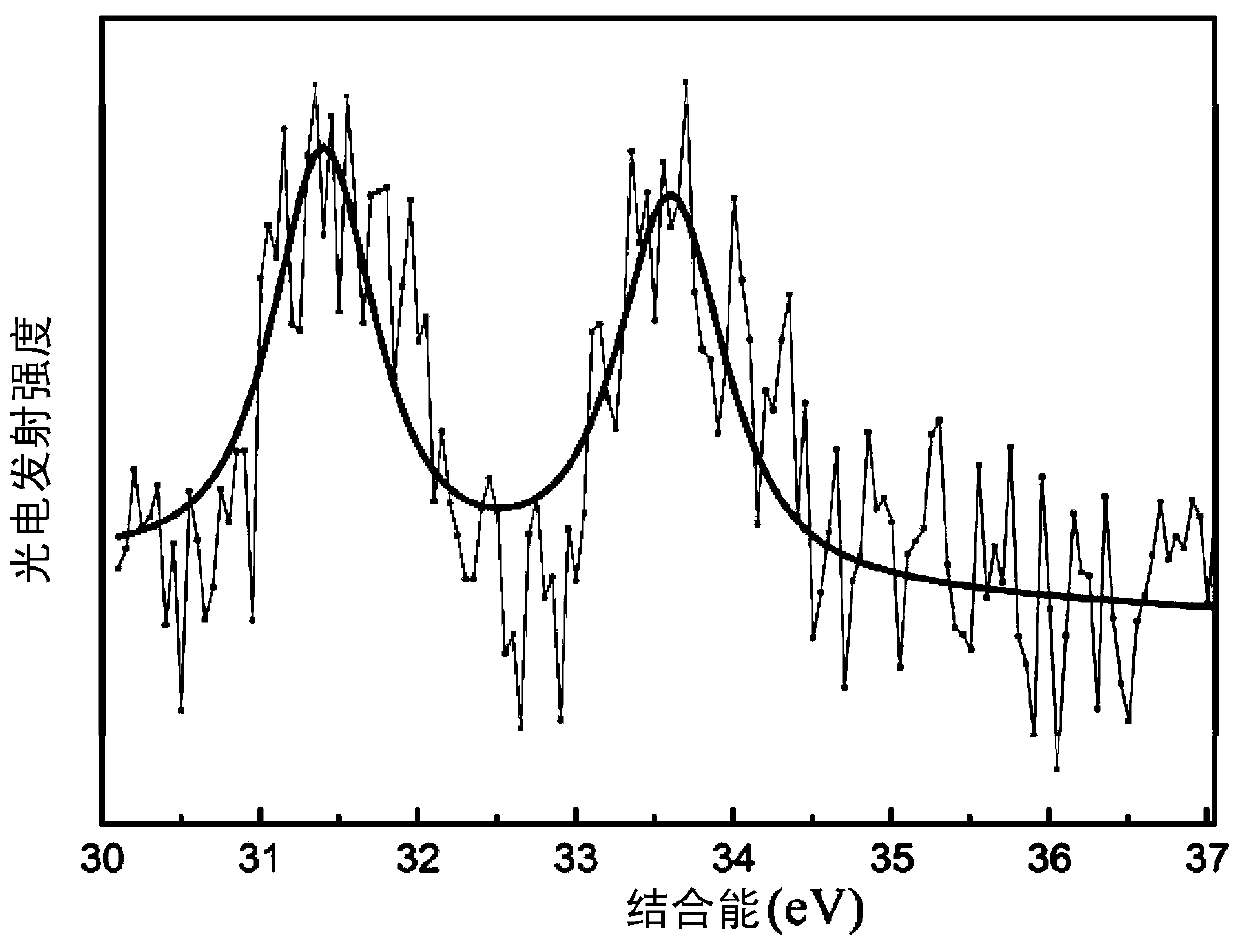

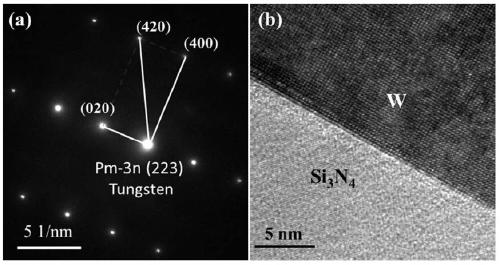

[0050] The obtained samples were polished for SEM-EDS micro-area component analysis, X-ray diffraction for chemical state analysis, and ultra-thin slices were prepared for TEM interface and electron diffraction analysis.

Embodiment 2

[0052] 15g of metal tungsten chopped fiber with a diameter of 10μm, 6g of magnesium oxide powder, 5g of ytterbium oxide powder, 2g of silicon oxide powder, and 72g of silicon nitride powder are placed in a silicon nitride ball mill jar, and 120g of absolute ethanol and 200g of nitrogen are added Silicon grinding ball;

[0053] Planetary ball mill ball milling for 8 hours, drying in an oven at 60°C for 6 hours, and sieving with 40 mesh to obtain powder raw materials;

[0054] The powder is formed by direct 250MPa cold isostatic pressing;

[0055] The samples were sintered at 1520°C for 5h under 0.5MPa nitrogen pressure to complete the sintering.

[0056] The obtained samples were polished for SEM-EDS micro-area component analysis, X-ray diffraction for chemical state analysis, and ultra-thin slices were prepared for TEM interface and electron diffraction analysis.

Embodiment 3

[0058] 50g of rod-shaped metal tungsten-rhenium alloy (W-3Re) powder with a diameter of 1μm and a length of 5μm, 3g of alumina powder, 9g of yttrium oxide powder, and 38g of silicon nitride powder were placed in a silicon nitride ball mill jar, and 100g of Water ethanol, 200g silicon nitride grinding ball;

[0059] Planetary ball mill ball milling for 4 hours, drying in an oven at 80°C for 4 hours, and sieving with 80 mesh to obtain powder raw materials;

[0060] The powder is formed by 10MPa dry pressing and 200MPa cold isostatic pressing;

[0061] The samples were sintered at 1760°C for 2 hours under 10MPa nitrogen pressure.

[0062] The obtained samples were polished for SEM-EDS micro-area component analysis, X-ray diffraction for chemical state analysis, and ultra-thin slices were prepared for TEM interface and electron diffraction analysis.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com