Chinese fir anticorrosion modification agent and preparing method and constructing process thereof

A treatment agent and technology for fir, applied in the field of anti-corrosion modified treatment agent for fir and its preparation, can solve the problems of polluting the environment, active ingredients, unstable size, easy loss of fir, etc., and achieves improved dispersibility, good chemical stability, improved The effect of corrosion resistance and corrosion stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

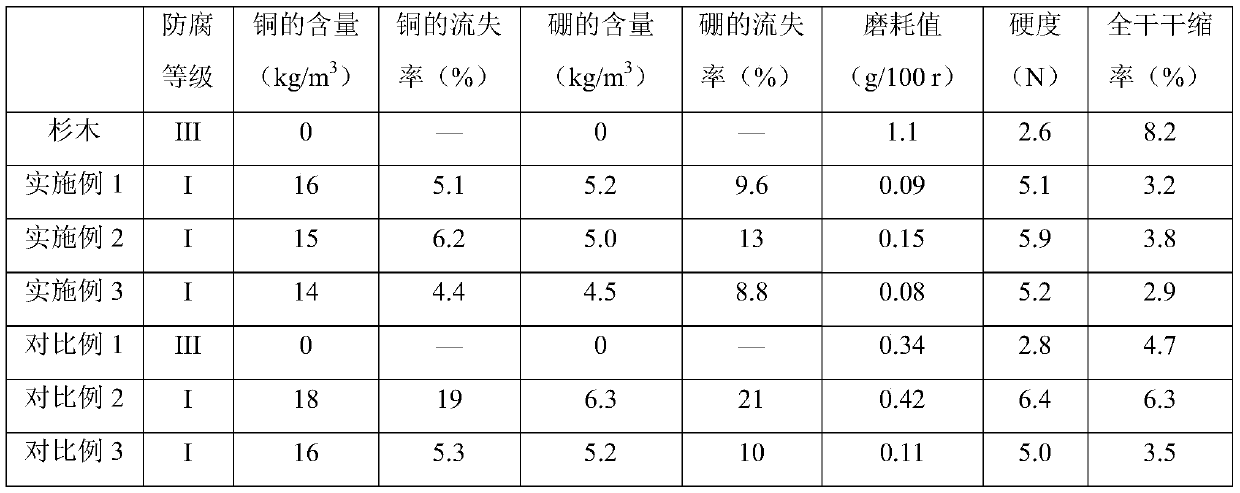

Examples

Embodiment 1

[0025] A preparation method of fir anticorrosion modification treatment agent, characterized in that: the specific steps are as follows:

[0026] Add 40g of copper ion and borate ion-supported graphene oxide, 250g of water-based polyurethane, 4.5g of didecyldimethylammonium chloride and 4.5g of polyoxypropylene oxide ethylene glyceryl ether into 1500mL of water, and mechanically stir for 90min at room temperature , and then sonicated for 90 minutes, and finally mechanically stirred for 45 minutes to prepare the fir anticorrosion modification treatment agent.

[0027] In the graphene oxide supported by copper ions and borate ions, the weight percentage of copper ions is 17.7%, and the weight percentage of borate ions is 10.5%.

[0028] A kind of construction technology of Chinese fir anticorrosion modification treatment agent, it is characterized in that: comprise the following steps:

[0029] (1) Place the dried Chinese fir sample in an automatic vacuum pressurized tank, evac...

Embodiment 2

[0032] A preparation method of fir anticorrosion modification treatment agent, characterized in that: the specific steps are as follows:

[0033] Add 20g of copper ion and borate ion-supported graphene oxide, 100g of water-based polyurethane, 2g of sodium polyacrylate and 1g of polyoxyethylene polyoxypropanolamine ether into 1000mL of water, mechanically stir for 60min at room temperature, then sonicate for 60min, and finally Stir mechanically for another 30 minutes to prepare the fir anticorrosion modification treatment agent.

[0034] In the graphene oxide supported by copper ions and borate ions, the weight percentage of copper ions is 21.9%, and the weight percentage of borate ions is 13.6%.

[0035] A kind of construction technology of Chinese fir anticorrosion modification treatment agent, it is characterized in that: comprise the following steps:

[0036] (1) Place the dried fir sample in an automatic vacuum pressurized tank, evacuate to a vacuum degree of 0.03MPa, and...

Embodiment 3

[0039] A preparation method of fir anticorrosion modification treatment agent, characterized in that: the specific steps are as follows:

[0040] Add 60g of copper ion and borate ion-supported graphene oxide, 400g of water-based polyurethane, 8g of didecyldimethylammonium chloride and 10g of defoamer DF681F into 2000mL of water, mechanically stir for 120min at room temperature, and then sonicate for 120min. Finally, mechanically stir for 60 minutes to prepare the Chinese fir anticorrosion modification treatment agent.

[0041] In the graphene oxide supported by copper ions and borate ions, the weight percentage of copper ions is 12.2%, and the weight percentage of borate ions is 7.55%.

[0042]A kind of construction technology of Chinese fir anticorrosion modification treatment agent, it is characterized in that: comprise the following steps:

[0043] (1) Place the dried Chinese fir sample in an automatic vacuum pressurized tank, evacuate to a vacuum degree of 0.06 MPa, keep ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com